Metso expands availability of its mill liner recycling service to the North American market

In response to the growing demands of its mining customers, Metso is strengthening its position as a supplier of innovative sustainable solutions with the introduction of its unique circularity process to the North American market.

The mill liner recycling service is a concrete example of how Metso can drive the mining industry towards more sustainable practices and a circular economy. With less unprocessed waste material sent to landfills, recycling helps to reduce CO2 emissions and improve environmental efficiency.

“Metso is expanding its recycling capabilities for the North American market by leveraging our experience with previous operations and customer cases in Europe and South America,” stated Giuseppe Campanelli, president of North America market area, Metso.

“Our service model in North America will be based on a modular solution, which gives us an interesting opportunity to bring the recycling process close to customer locations in the United States, Canada and Mexico. The availability of the service will be based on customer needs and demand.”

Pioneering recycling service for sustainable mining

Metso is committed to developing pioneering sustainable technologies and solutions for the global mining industry. Circular economy is one of the important areas of sustainability development throughout the industry. As part of Metso’s extensive mill lining offering, the company is developing ways to increase the use of recycled materials in liners to further close the circularity loop.

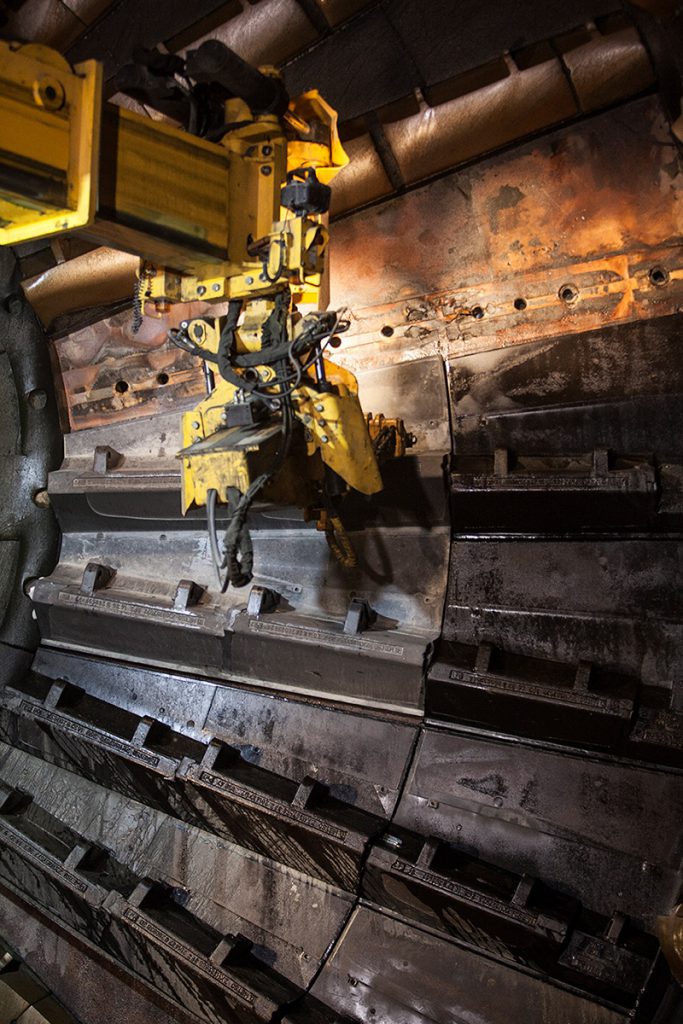

The recycling service is facilitated by an innovative technology that enables safe and efficient separation of different rubber and metal liner components, like cast inserts, wear plates, and backing plates. Composite liners, like Megaliner and Poly-Met liners, can be processed using this solution.

“As a responsible supplier and partner for sustainable wear solutions, we have set ambitious targets to help our customers reduce the environmental impact of mining in the different stages of the production process,” said Markus Marttiini, vice president, optimized mill lining products, Metso.

“Metso’s unique solution enables the efficient separation of different liner materials so that the valuable components can be reused in the manufacturing of new products.”

More News

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments