Visualizing the size of mine tailings

Visualizing the size of mine tailings

On January 25th, 2019, a 10-meter tall wave traveling 120 km/h, washed 10 million m3 of mining waste from the Brumadinho tailings dam over the Brazilian countryside killing somewhere between 270 and 320 people.

This was a manmade disaster, made from mining the materials we use daily. Every copper wire in your house, steel frame in an EV, or any modern appliance comes from mining.

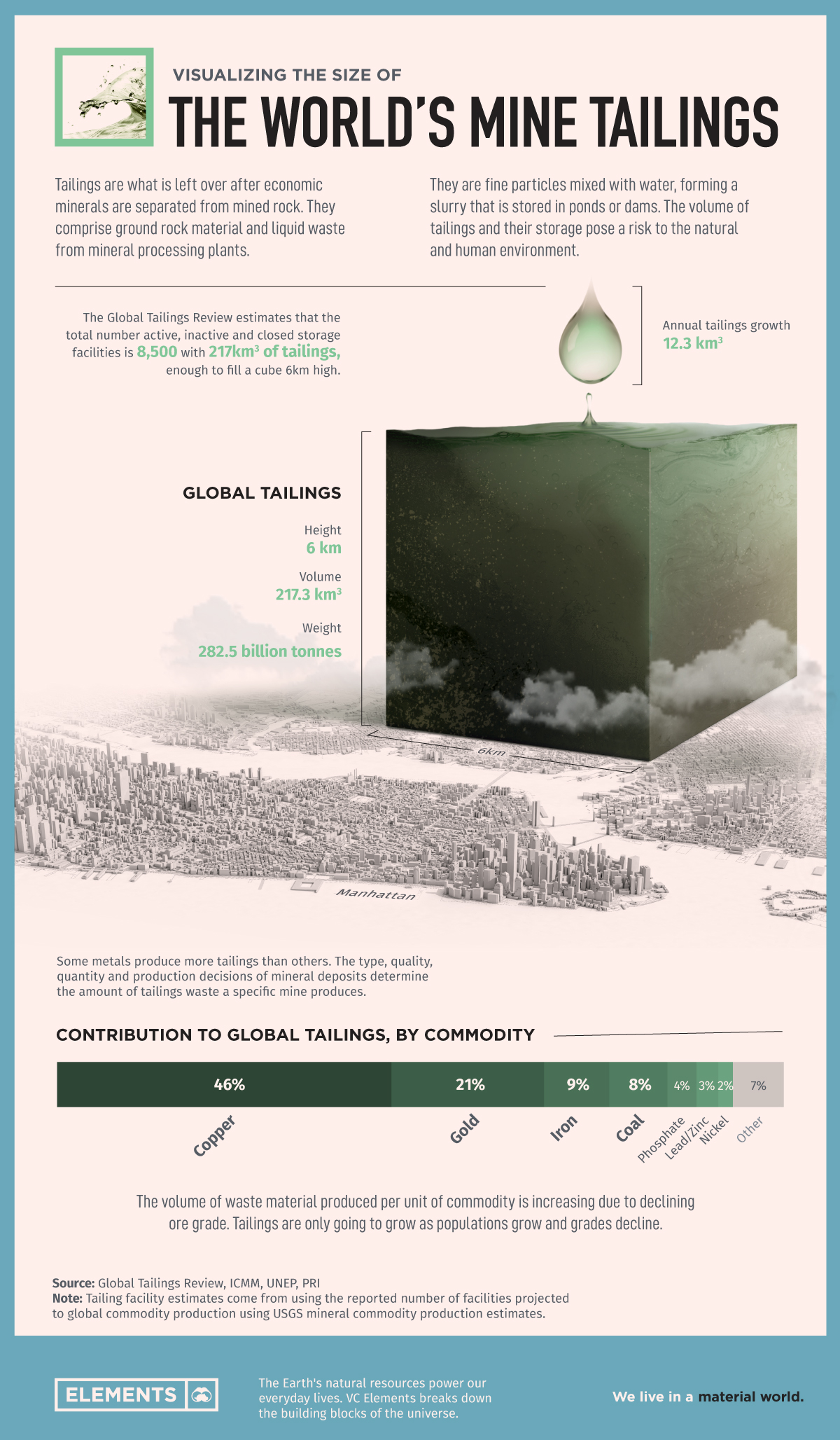

Mining leaves behind waste in the form of tailings stored in dams or ponds around the world. This infographic takes a look at the estimated size of one part of this waste, tailings, visualized next to the skyline of New York City as a benchmark.

Quantifying mining’s material impact

In the wake of the Brumadinho tailings failure, the International Council on Mining and Metals (ICMM) began a review with institutional investors and the United Nations Environment Programme (UNEP), to survey tailings facilities around the world.

The Global Tailings Review tracked a total of 1,743 unique facilities containing 44,540,000,000 m3 of tailings. This dataset represents only 30.2% of global commodity production.

However, the review estimated the total number of active, inactive, and closed facilities is around 8,500. If we use the assumptions for the 1,743 estimate to calculate for the 8,500 facilities, a total of 217,330,652,000 m3 of tailings are in storage globally.

What are tailings?

Not all rock that comes out of the ground is metal. Miners find, remove, and refine rocks that carry a small amount of metal we need.

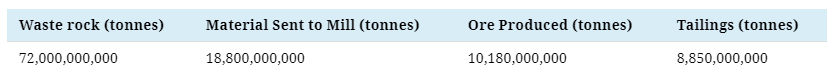

According to the USGS, 72 billion tonnes of material produced just over 10 billion tonnes of ore. Only 14% mined material makes it to processing for metals.

Tailings are what is left over after mills separate the metal from the mined rock. The processed material “tailings” comes from the “tail” end of a mining mill and comprise fine particles mixed with water forming a slurry. Mining companies will store this waste in dams or ponds.

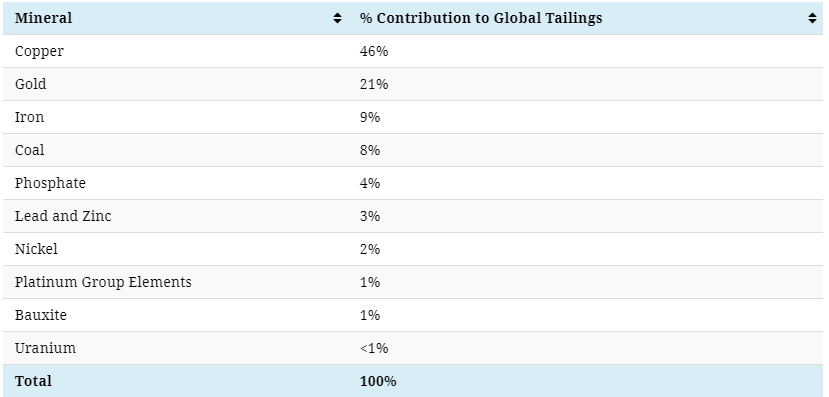

Not all minerals are equal: Tailings contribution by commodity

Not all minerals are equal in their contribution to tailings. The grade, quantity, and the process to extract the valuable metals affect each metal’s material impact.

A renewable future will be mineral intensive and will inevitably produce more mining waste, but growing awareness around mining’s true cost will force companies to minimize and make the most of their waste.

Turning a liability into an asset

While tailings are waste, they are not useless. Researchers know there remains economic value in tailings. Natural Resources Canada estimated that there is $10B in total metal value in Canadian gold mining waste.

Rio Tinto has produced borates from a mine in the Mojave Desert which has left behind more than 90 years’ worth of tailings. The company was probing the tailings for gold and discovered lithium at a concentration higher than other US projects under development.

According to UBC’s Bradshaw Initiative for Minerals and Mining professor Greg Dipple, the mining industry could help society store carbon. For over a decade, he has researched a process in which tailings naturally draw CO₂ from the air and traps it in tailings.

A material world

While the majority of mining companies manage tailing dams safely, the issue of the material impacts of mining on Earth remains.

Mining of metal has grown on average by 2.7% a year since the 1970s, and will continue to grow. The importance of the size of tailings is critical to address proactively, before it comes rushing through the front door, as it did in Brazil.

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments