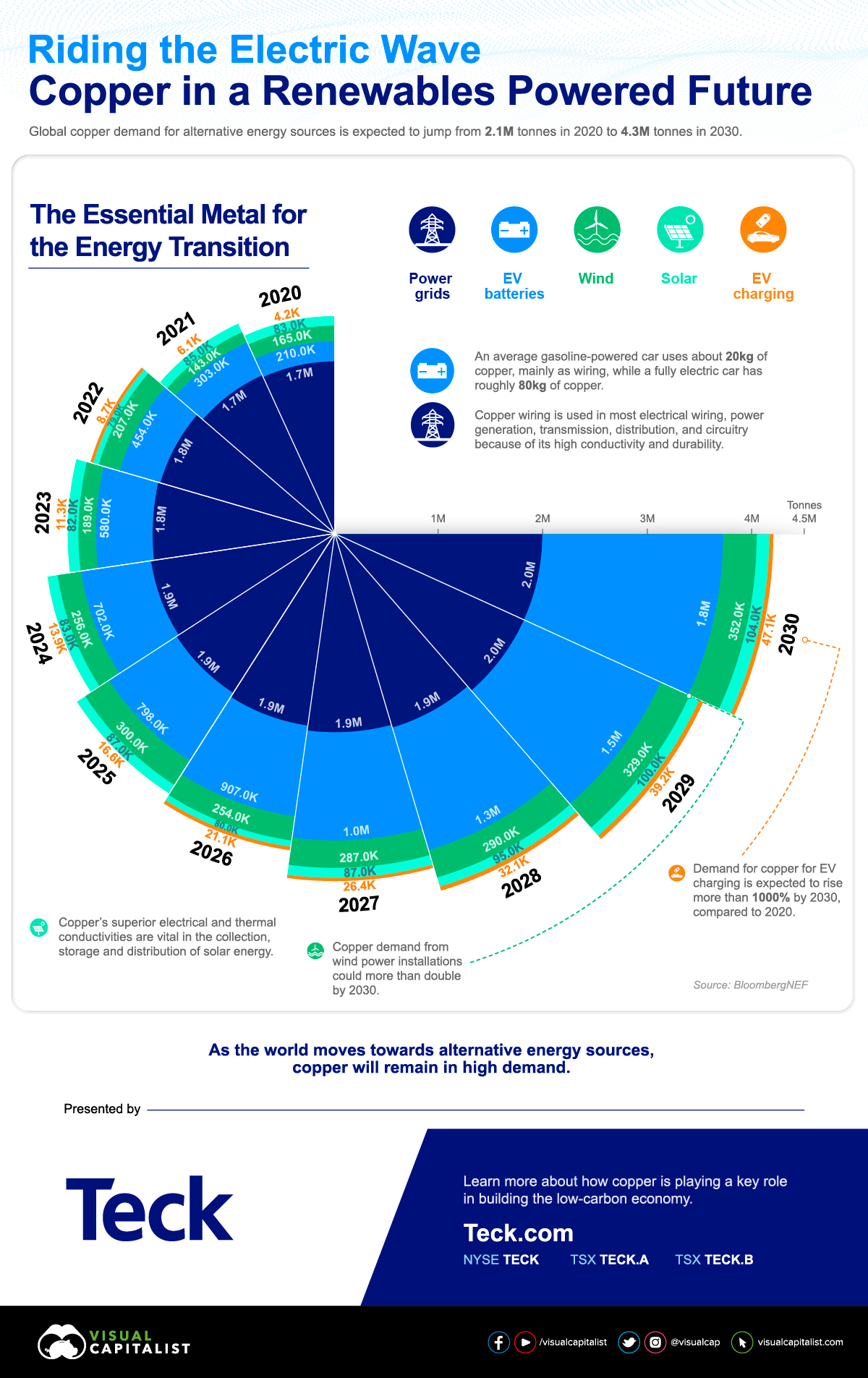

Visualizing copper demand for renewables

Visualizing Copper Demand in a Renewables Powered Future

Renewable energy is considered one of the most effective tools to reduce global carbon emissions and fight climate change. However, building technologies like solar and wind power plants or electric vehicles (EVs) can be mineral-intensive.

Copper is considered an essential metal for renewables. The metal is highly conductive, can easily be shaped into pipes, wires, or sheets, and can remove heat far more rapidly than other metals. In fact, copper itself is a sustainable material. The metal is 100% recyclable and can be used repeatedly without any loss of performance.

The Wind and Solar Boom

Copper has long been a common component in most electrical wiring, power generation, transmission, distribution, and circuitry because of its high conductivity and durability.

New energy technologies, however, require even more copper. Photovoltaics (PV) solar power systems contain approximately 5 tonnes (t) per megawatt (MW) of copper, while grid energy storage installations rely on 2.7 to 3.6t per MW.

Solar isn’t the only renewable energy source that relies on copper, as a wind farm can contain between 4 million and 15 million pounds of copper.

Copper Drives EVs

The clean transport sector also consumes lots of copper. In fact, the metal is used in every major EV component, from the motor to the inverter and the electrical wiring.

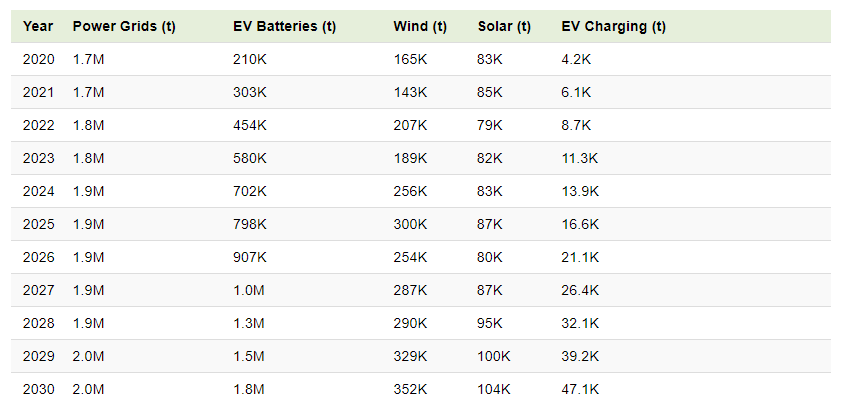

While an average gasoline-powered car uses about 20 kg of copper, mainly as wiring, a fully electric car has roughly 80 kg of copper. Therefore, copper demand for EV batteries alone is expected to jump from 210K tonnes in 2020 to 1.8M tonnes in 2030.

[Click here for an interactive chart of copper prices]

But demand for the metal won’t just come from the cars themselves. Copper used for EV charging stations is also expected to rise more than 1,000% by 2030, compared to 2020.

Meeting the Copper Demand

As the world moves towards alternative energy sources, copper will remain in high demand.

Even though the metal is 100% recyclable, recycling alone will not be enough to meet demand and ensure a stable supply of copper. Continued mining for new copper will be needed.

(This article first appeared in the Visual Capitalist)

More News

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments