Tesla in talks with BHP over nickel supply pact

Tesla is in talks with BHP on a nickel deal as the electric-car maker targets higher production and seeks to avoid a supply crunch, according to people familiar with the matter.

Talks are held up on pricing, and no final agreement has been reached so far between the automaker and BHP, the world’s largest miner, said one of the people, requesting anonymity because the talks are private. The discussions come as Tesla works to raise the amount of the metal used in vehicle batteries to improve performance, and as it makes a push into in-house cell production.

Nickel is a key component for the cathodes of EV batteries, and Tesla Chief Executive Officer Elon Musk has expressed concern about supply due to challenges in sustainable sourcing. A deal with Tesla may come as a surprise to some BHP investors since nickel makes up a small part of BHP’s business. It would signal real progress in the company’s efforts to expand in the space and retool the nickel division to serve battery makers.

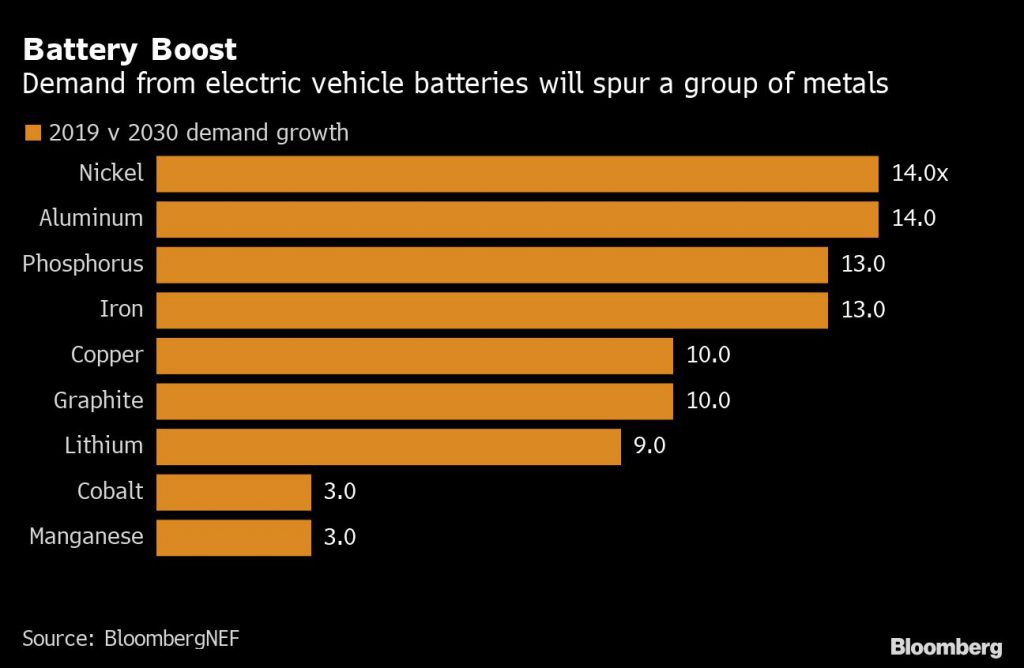

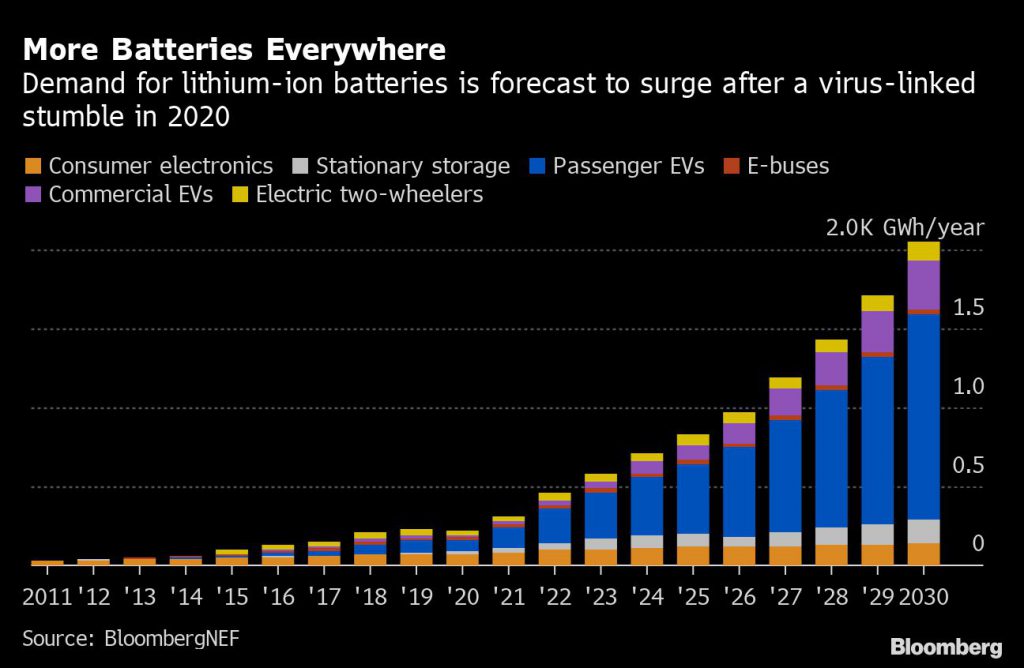

Demand for nickel is forecast to surge in coming years as Tesla expands and companies from BMW to Volkswagen add to their lineups of electric models

A spokesperson for BHP declined to comment. Tesla didn’t respond to an emailed request for comment.

Demand for nickel is forecast to surge in coming years as Tesla expands and companies from BMW AG to Volkswagen AG add to their lineups of electric models. Musk in July promised a “giant” contract to miners that produce the metal in an “environmentally sensitive way.” Nickel can help pack more energy into batteries, and allows producers to reduce use of cobalt, which is more expensive and typically has a less transparent supply chain.

Musk indicated last month his firm had been in contact with several nickel producers, without identifying the companies.

“We really need to make sure that we’re not constrained by total nickel availability — I actually spoke with the CEOs of the biggest mining companies in the world and said please make more nickel,” Musk told investors in a presentation last month.

The market for battery-grade nickel should be in a tight balance in the next two to three years as demand from lithium-ion battery producers picks up, BloombergNEF analyst Allan Ray Restauro said by email. There may be a significant deficit as early as 2023, when nickel prices start to recover, he said.

“Nickel demand will grow significantly off the back of batteries and the EV thematic, and that will pull nickel prices up,” BHP CEO Mike Henry said in an interview last month.

BHP is focused on expanding its Nickel West unit after abandoning earlier plans to sell the assets and as it shifts away from traditional customers in the stainless-steel industry. The miner’s nickel division now sells more than 75% of output to the battery-supply chain in Japan, South Korea and China, up from less than 5% in 2016, the unit’s asset president Eduard Haegel said last year.

The producer agreed in June to buy an Australian project that holds one of the country’s biggest untapped reserves of nickel from MMC Norilsk Nickel PJSC, and is partnering with a smaller company on exploration in Quebec.

BHP has held extensive talks with companies in the battery sector, Henry said, declining to specify if those discussions included recent conversations with Tesla. “We’ve been pro-actively pursuing and talking to a lot of manufacturers globally for a while now,” he said.

Tesla agreed to a deal in June to buy cobalt from Glencore Plc, and in recent weeks struck a five-year raw-materials pact with Piedmont Lithium Ltd., developing a lithium project in North Carolina.

Brazil’s Vale SA, the top commercial nickel producer, has also talked with Tesla.

“As a world leader in the production and supply of responsibly-sourced nickel, Vale has engaged in talks with stakeholders at all points along the supply chain, including Tesla, to explore the possibility of partnerships,” the Rio de Janeiro-based company said in an emailed response. “This is consistent with Vale’s positioning in the market, the quality of our product and the increasing demand for nickel as a critical component of battery manufacturing for electric vehicles.”

(By Yvonne Yue Li and David Stringer, with assistance from James Attwood)

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments

cacarr

Does BHP have access to nickel sulfide deposits?