Russell: Iron ore quality premium widens to record amid China demand, lower inventories

(The opinions expressed here are those of the author, Clyde Russell, a columnist for Reuters.)

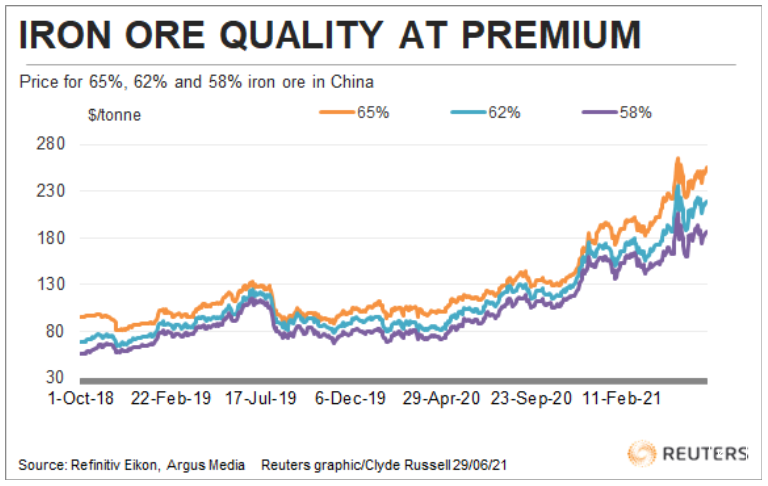

The spread between low- and high-grade iron ore has blown out to the highest on record in dollar terms, suggesting Chinese steel mills are trying to maximise output by using as much of the best quality ore as possible.

Iron ore has been one of the standout commodity performers during the recovery from the coronavirus pandemic as robust demand from China, which buys about 70% of all seaborne volumes, collided with supply issues from top exporters Australia, Brazil and South Africa.

Benchmark 62% iron ore for delivery to north China, as assessed by commodity price reporting agency Argus, has surged 175% from its 2020 low of $79.85 a tonne in March last year to the close of $219.60 on Monday.

For the current episode of wider premiums to moderate, it’s likely that inventories will have to climb

It climbed to a record of $235.55 a tonne on May 12, but has since slipped back slightly as the authorities in China announced a series of measures designed to cool the red-hot sector – steps that have largely failed to sustainably lower prices.

With the spot price rising to a record and remaining at elevated levels, a further sign of the strength in Chinese demand is the premium that steel mills are prepared to pay for higher quality iron ore: using the latter provides more steel for the same amount of input of iron ore and the coking coal used to fuel the blast furnaces.

Ore with a 65% iron content ended at $255.35 a tonne on Monday, or $35.75 higher than the close for the 62% grade.

The top grade was also $68.65 a tonne above lower-quality 58% ore, which ended at $186.20 on Monday.

In dollar terms, the spreads between the three main iron ore grades have in recent weeks surged to the widest since Argus started assessments in 2013.

However, they are not quite the biggest on record in percentage terms.

At Monday’s close, 65% ore was priced 16.3% above the 62% grade, which in turn was 17.7% higher than the 58% material.

The premium of 65% ore over 62% was exceeded in late October 2018, when the 65% grade commanded a 28.7% premium over 62%.

Inventories

It’s worth looking at what was happening at that time in China’s iron ore and steel markets to see if there are any useful parallels to the current situation.

The most obvious similarity is that the widening of the spread between grades in late 2018 and currently both came at a time of record high steel output and sustained declines in iron ore inventories at Chinese ports.

Chinese steel production reached a then-record of 2.7 million tonnes per day in September 2018. Daily output set a new record of 3.26 million in April this year, and monthly production hit an all-time high in May, even though daily output was slightly below the prior month’s record at 3.21 million.

Iron ore port inventories have been trending lower since reaching a 2021 peak of 135.9 million tonnes in the week to April 24, falling to 123.9 million in the seven days to June 25.

In late 2018, inventories were in a similar pattern, dropping from a peak that year of 161.9 million tonnes in early June to a low of 136.2 million by early December 2018.

What’s different between the two time periods is that in late 2018 Chinese steel mills were trying to maximise output ahead of production curbs implemented over the northern hemisphere winter as part of efforts to limit pollution from energy-intensive industries.

Now, the steel mills are trying to produce as much as possible given strong profit margins amid robust demand. China continues to enjoy the impact of stimulus spending put in place to boost the economic recovery from the coronavirus pandemic.

The experience of late 2018 shows that when iron ore inventories started rising again in early 2019, the spread between the various grades started contracting, even though prices for all three continued to rise.

The end of winter pollution curbs also helped to narrow the premium of higher-grade iron ore.

For the current episode of wider premiums to moderate, it’s likely that inventories will have to climb, and perhaps steel demand growth will have to slow as well.

(Editing by Kenneth Maxwell)

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments