Robots help ‘smart mines’ drive China’s coal build-out

Deep beneath the earth’s surface in a remote corner of northern China, a mechanical monster comes to life. Two massive discs armed with dozens of metallic teeth begin spinning against a solid wall, spraying dust and shiny black chunks of coal.

Engineer Zhang Luoxun watches it all from an airy office about 300 meters above. Cameras and sensors connected to an underground 5G network feed live images and information on everything from mine shaft stability to air quality to Zhang and his colleagues above ground.

The technology helped the Xiaobaodang mine owners reduce the number of underground workers and convince regulators to let them stretch out the coal face to a record 450 meters long. Every day the whirling six-foot-diameter discs cut into a small portion of it, dislodging about 35,000 tons of coal, nearly enough to theoretically power Ireland.

“This is the most advanced coal mining face in China,” Zhang said.

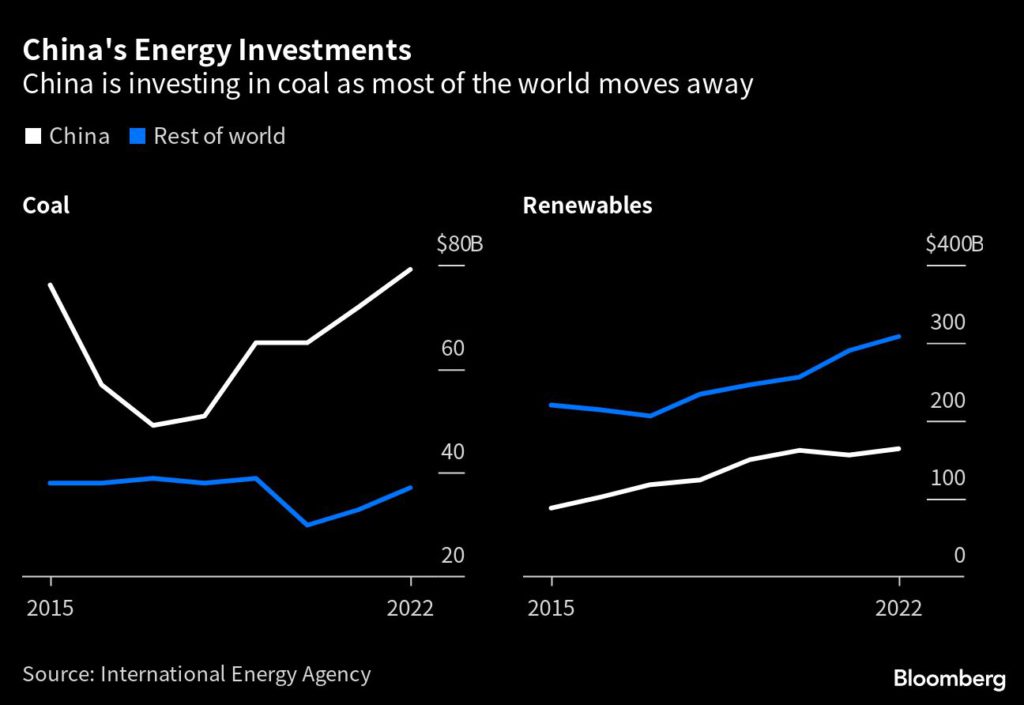

Xiaobaodang is just one example of China’s relentless push to invest more in the coal industry at a time when many countries and financial institutions are backing away from the most polluting fossil fuel. China invested $79 billion in coal production last year, according to the International Energy Agency, while the rest of the world combined spent $37 billion.

To be sure, China’s coal spending is nothing compared to its outlay for renewables, which reached a record $164 billion last year. Officials have said they expect coal to slowly morph from the country’s dominant energy source to a backup fuel as cheaper wind and solar take a larger share.

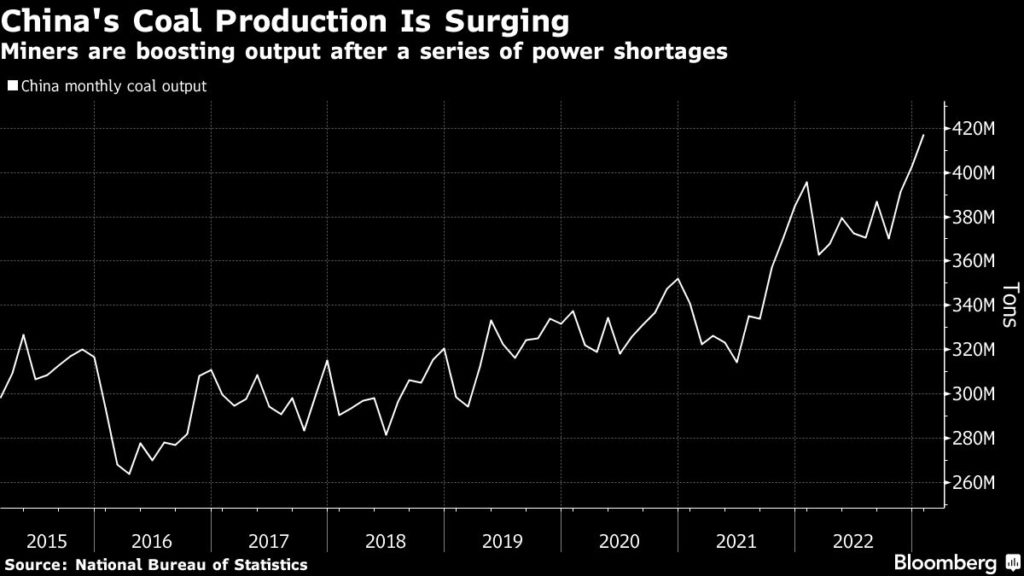

But that still means years and possibly decades of strong coal demand. National Energy Administration Director Zhang Jianhua earlier this month called coal China’s “ballast stone” for guaranteeing energy. Beijing has pushed its state-owned mining giants to ramp up output to record levels after a shortage of coal caused widespread power shortages in late 2021. Adding coal reduces the need to import more expensive liquefied natural gas, the price of which soared last year after Russia’s invasion of Ukraine.

Xiaobaodang is owned by one of those state-owned miners, Shaanxi Coal & Chemical Industry Group Co. China’s No. 5 coal producer had output of 230 million tons last year and netted a record 60 billion yuan ($8.7 billion) in profits, said Vice General Manager Liu Weimin.

The company is investing some of that money back into upgrades at mines like Xiaobaodang and Hongliulin, located on the edge of the Ordos Desert.

Beneath the ground is a maze of tunnels and shafts that workers enter in vans and trucks, slowly driving for kilometers on a gentle descent.

The coal face itself is a long borehole with shimmering black material on all sides, filled with cool, damp air smelling of sedimentary must. Wide, yellow shearers carve into the seams, and the dislodged fuel is dispatched on conveyor belts through processing equipment and ultimately out of the mine to storage silos and a train-loading terminal.

About every two to three meters along the coal face are closed circuit cameras connected to 5G routers supplied by Huawei Technologies Co., which partnered with the mines to automate their systems and this week facilitated a tour of the sites for reporters and mining experts.

At Hongliulin alone more than 2,700 pieces of underground mine equipment are connected to networks to instantaneously transmit photos, videos and operational data to the surface. Miners take video calls with managers underground, and can even scroll through social media during their breaks.

Signs of the investment in automation are everywhere: Humans are no longer needed to monitor power substations or massive water pumps, ceding that job to sensors and robots with cartoon-like heads that slowly patrol the rooms, or hang upside down from a rail like a sloth. Xiaobaodang is even experimenting with automated trucks to drive workers in and out of the mine.

From a pilot program with 71 mines in 2020, China now has about 570 “smart mines” that use technology to optimize the production of about 1.9 billion tons annually, about 42% of the nation’s total, according to industry publication China Coal News.

Mine operators are seeking to improve efficiency and regulators are pushing for enhanced safety and increased digitalization, according to Xu Jun, chief technology officer for Huawei’s mining division. Automation can save on labor costs — especially important given mining’s aging work force — and fewer accidents will reduce downtime, lifting output, he said.

Chinese regulators are also favoring sites that deploy advanced equipment for approvals, according to China Coal News.

“We see the mining industry as low-hanging fruit,” Xu said. “It’s an industry that’s been ignored by tech for too long.”

While mine safety has improved in China over the past decade as stronger safety regulations were enforced and the government closed smaller operations, the country still recorded more than 600 mining deaths last year. A February landslide at a coal mine development in Inner Mongolia left more than 50 workers dead or unaccounted for in one of the worst industrial accidents in recent memory.

Hongliulin has invested hundreds of millions of yuan on systems that reduce the number of people on site, according to Shi Chao, director of the mine’s intelligent management center. The site can operate teams with as few as six miners, compared to some traditional sites that would require 20 people per crew.

“We’d like to get all our people above ground eventually,” Shi said.

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments