Japan’s top steelmaker eyes $700 million ‘green steel’ project

Japan’s biggest steelmaker is considering a major investment in a green steel project powered by hydrogen as a global push to decarbonize one of the world’s most polluting industries gathers pace.

Nippon Steel Corp. is exploring a project outside its home market that may cost an estimated 100 billion yen ($733 million) or more, according to Takahiro Mori, executive vice president who oversees global operations. Australia and Brazil are among possible sites, where high-grade iron ore is accessible along with cheaper electricity than in Japan, he said in an interview.

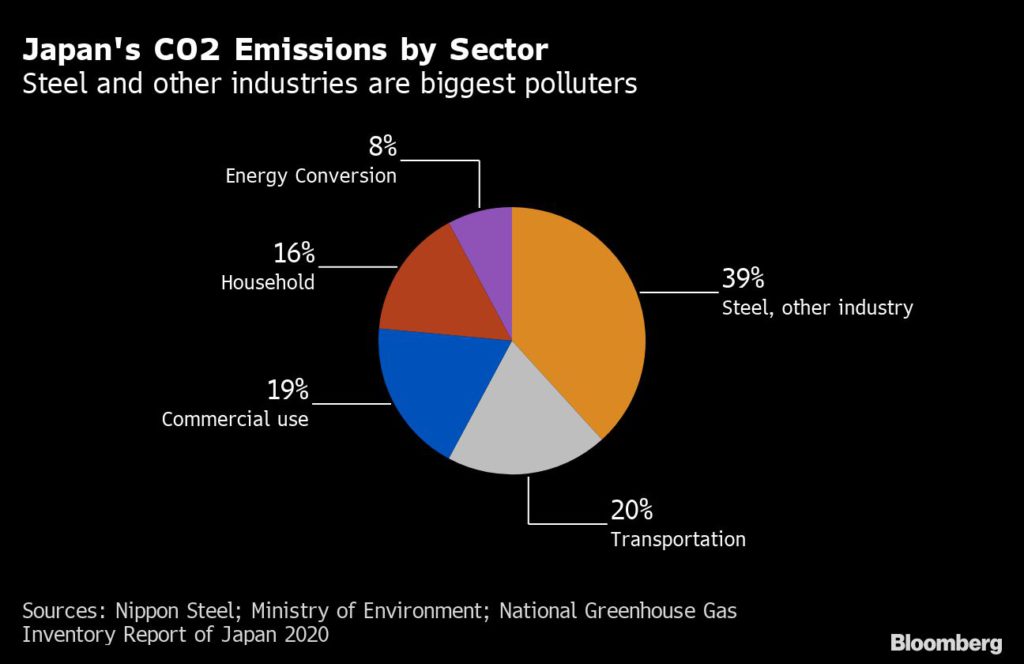

Steel is one of the building blocks of the global economy — needed for infrastructure, autos and appliances — and while demand is set to go on rising, producers are exploring ways to cut their carbon footprints. The industry is one of biggest polluters as it currently relies on coal-fired blast furnaces, particularly in Asia, which accounts for more than 70% of global output.

“We can’t avoid pathways toward carbon neutrality,” Mori said. “We are currently comparing several projects to see if there’s anything that meets the conditions for green-steel manufacturing or investment.”

Nippon Steel and peers ArcelorMittal SA, the world’s biggest steelmaker outside of China, and China Baowu Steel Group have all pledged to become carbon neutral by the middle of this century. Elsewhere, South Korean rival Posco recently announced a plan to invest $40 billion in hydrogen manufacturing as well as green steel with partners in Australia by 2040.

Replacing coal

There’s no real difference between conventional steel and its green counterpart and the distinction lies in the way it’s manufactured, although there’s no defining standard or criteria. Traditionally, steel is made by heating iron ore with coking coal in a blast furnace. One way to decarbonize the process and cut emissions is to replace the fossil fuel with hydrogen.

To meet its carbon goal, Nippon Steel plans to boost the use of hydrogen in existing blast furnaces, as well as building 100% hydrogen-based so-called direct-reduction plants. In addition, it’s making more recycled metal by remelting scrap in electric-arc furnaces. The company plans to cut emissions by 30% by the end of the decade as a way station to carbon neutrality by 2050.

Japan’s high electricity costs present a hurdle for domestic production, prompting the company to search for opportunities outside the country, according to Mori. “It would be best if we could work on a direct-reduction process using hydrogen in Japan, but that won’t be easy,” he said.

Nippon Steel’s domestic rival, JFE Holdings Inc., is also concerned about higher costs for hydrogen and electricity in Japan. It’s open to options, including working on a hydrogen-based project in Australia, Masashi Terahata, executive vice president, said in an interview in Tokyo on Friday.

“If we are able to get access to low-priced hydrogen in Japan, we will work on the project at home,” Terahata said. “If not, that means we can’t do in Japan.”

(By Masumi Suga)

Related Article: Nippon Steel could buy more stakes in coking coal and iron ore mines

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments