International Graphite opens pilot processing plant in Western Australia

Australia’s International Graphite opened a test graphite processing plant in Western Australia on Friday, as the state moves to add value in the battery processing chain.

It comes as Australia seeks to develop its critical minerals processing industry, with Treasurer Jim Chalmers on Friday encouraging investment from allies to build up the sector.

The plant has already produced micronized and spheroidized graphite, providing proof of concept that Western Australia has the capacity to produce graphite material for battery anodes, the materials developer said in a statement.

The next step is for it to make products to meet specifications for international customers, it said.

“By the end of 2023 we expect to be completing construction and commissioning of a commercial scale graphite processing plant,” Executive Chairman Phil Hearse said in the statement.

The plant opening was carried out by Mark McGowan, the premier of Western Australia, which has invested A$2 million ($1.35 million) in the facility.

Related Article: Graphite poised to do a lithium

The developer is also setting up a research laboratory that will have an ultra-high temperature furnace that will be used to develop a thermal graphite purification process.

By 2025, it expects to have developed a fully integrated battery anode project with feedstock coming from its planned graphite mine at Springdale on the state’s south coast.

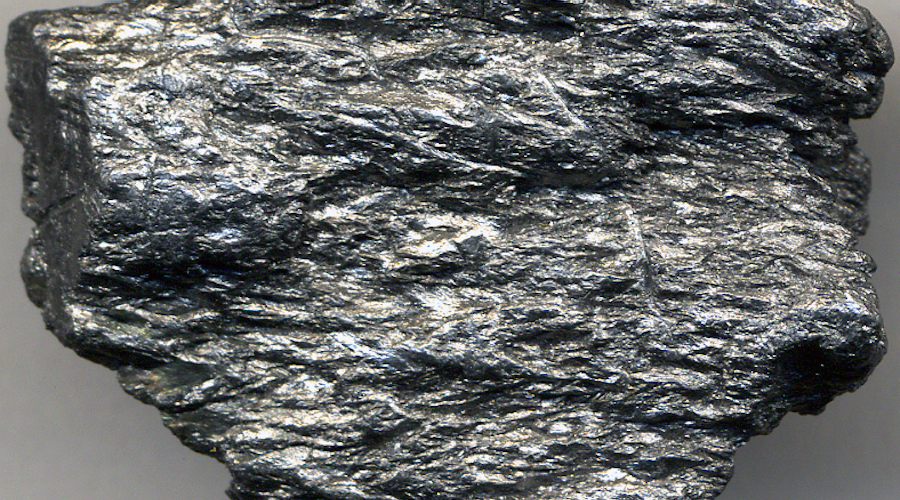

Graphite is a key material used in battery anodes, of which China is the world’s major producer.

Purified micronized graphite is used as a conductive additive to battery cathodes, and other industrial applications, and well as being an essential step in the production of purified spheroidized graphite for battery anodes.

($1 = 1.4778 Australian dollars)

(By Melanie Burton; Editing by Ana Nicolaci da Costa)

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments