Insight: Inside a copper output plunge at No. 1 global producer Codelco

Beneath the world’s largest open-pit copper mine in Chile lies a tunnel complex filled with dust so dense that machines frequently break down and workers can’t operate without spacesuit-like helmets.

Conveyer belts often stall and have caused at least one fire. Construction mistakes have led to collapses and two large electromagnets designed to clear damaging objects haven’t been functional in four years.

This, according to over a dozen workers interviewed by Reuters, is the situation at Chuquicamata Subterranea (PMCHS), a $5 billion dollar flagship project of Chile’s state copper miner Coldelco that was meant to transform the open-pit mine into an underground operation.

Codelco chairman Maximo Pacheco, asked by Reuters about the workers’ complaints, did not dispute their accounts and said the company had learned from its past mistakes.

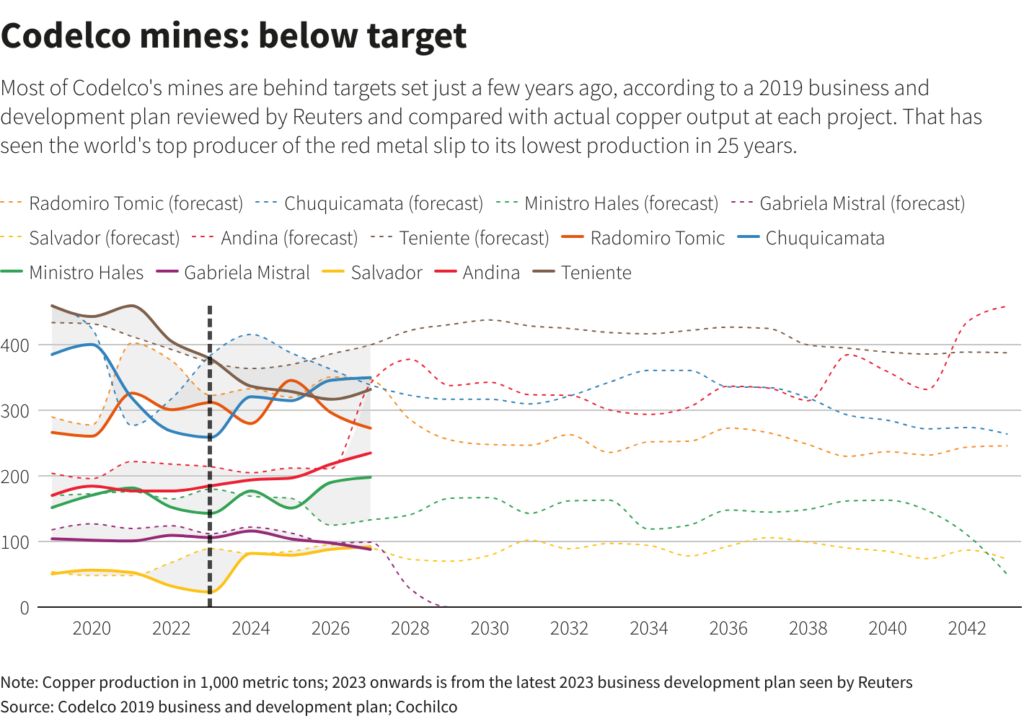

PMCHS is one of four mega projects Codelco has launched, called structural projects, designed to extend the life of its key mines and compensate for a drop in ore grades.

As the world races towards cleaner energy, demand for copper – used as a conductor in everything from wind farms to solar panels – is skyrocketing. The average electric car uses four times as much copper wiring as an internal combustion car.

Chile is the world’s largest supplier of the red metal and Codelco accounts for just over a quarter of the country’s output.

The overhaul at PMCHS should extend the mine’s lifespan by 50 years but the underground mine has been dogged by delays, collapses and construction difficulties.

After it was inaugurated in 2019, PMCHS was expected to produce 385,000 metric tons in 2023. Instead, it produced 268,000 in 2022 and just 178,000 in the first nine months of 2023 due to the slower rollout of the project.

Reuters spoke to more than a dozen Codelco employees at key mines, headquarters and unions, and reviewed hundreds of pages of internal company reports, financial statements and regulatory documents and investigations to assess the causes behind the delays.

The employees, who asked not to be identified due to confidentiality agreements, said there had been no accountability for the management team and top-level executives despite financial troubles, worker injuries and even deaths.

Chile’s Sernageomin mining regulator told Reuters that Codelco had been sanctioned 29 times since 2021 and has had seven fatal accidents. Most of the incidents were in project construction and not routine mining operations, it said.

“While the accidents have different causes, there are certain common factors related to breaches in control mechanisms,” the agency told Reuters.

In an interview at Codelco headquarters in Santiago, Pacheco said there had been a lack of maintenance partly due to supply chain and staffing issues during the COVID-19 pandemic. This caused a series of delays and equipment failures that are still being felt, he said.

“We didn’t do programmed maintenance during COVID because we focused all our efforts on maintaining production,” said Pacheco, appointed in March 2022. “Now we’re paying for that.”

Delays in structural projects also affected maintenance since the company was forced to keep using machinery it had planned on retiring after new projects came online.

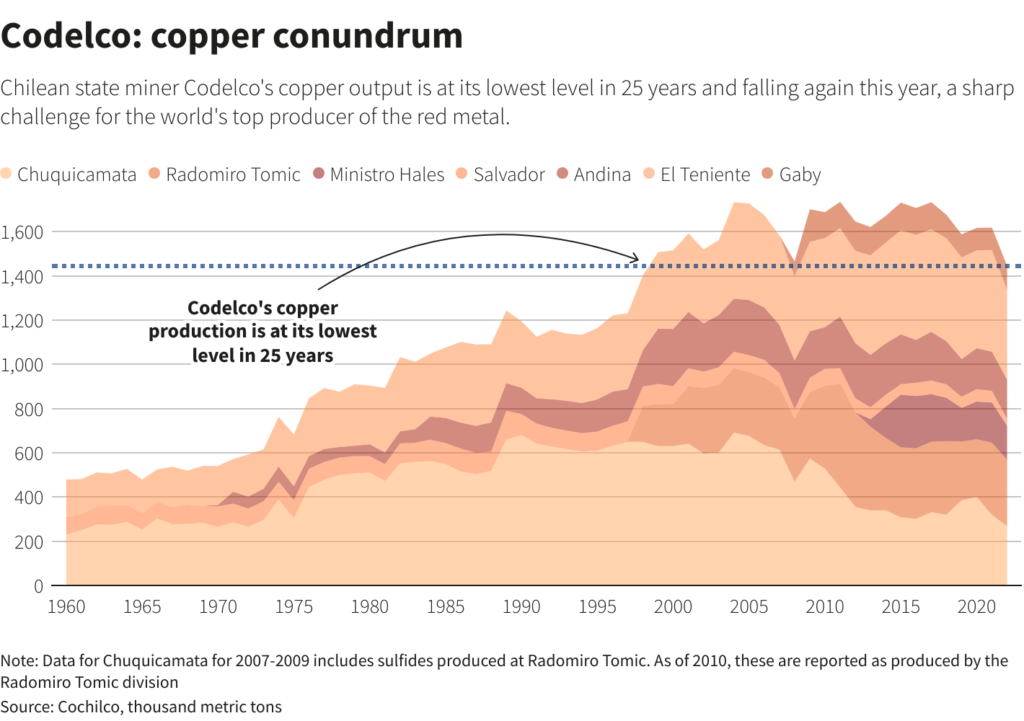

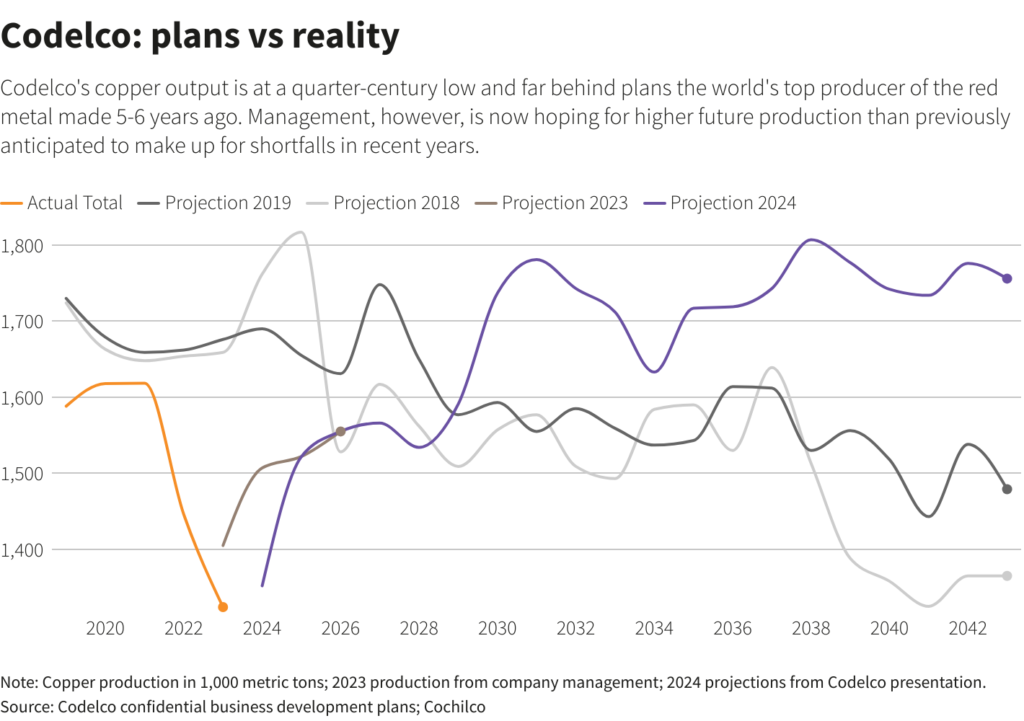

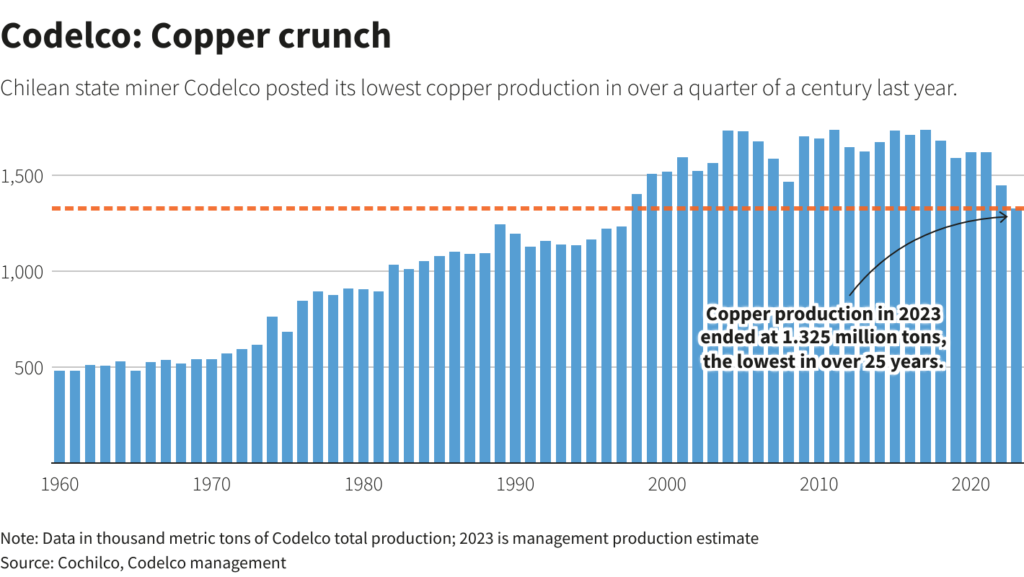

Pacheco said a drop in ore grade, extreme weather events such as a drought and then heavy floods in 2023, combined with accidents at mines also hurt production. Overall production fell to 1.325 million metric tons last year from 1.62 million in 2021.

Pacheco and other executives said they expect the slump to revert in 2024 as more projects come online and Codelco’s Ministro Hales mine normalizes operations after a massive landslide in 2022.

On Jan. 18, Codelco said it would invest an additional $720 million in PMCHS. The project, originally launched with several others in 2008, was supposed to see construction finished by 2017, but that’s now delayed until 2025.

Pacheco said the company would dedicate more resources to maintenance and put a strict monitoring process in place.

“We make mistakes here,” Pacheco said, refering to the workers’ complaints about executive impunity. “I understand people want every mistake to be paid with blood. I prefer that mistakes are paid with lessons learned.”

Chuquicamata’s maintenance woes

Five of the workers Reuters spoke to said many of the problems stemmed from when management from Codelco’s El Teniente mine, the world’s largest underground copper deposit, took over the PMCHS project in 2019 but failed to adjust for Chuquicamata’s geology compared to the rocky mountains of El Teniente.

Located in Chile’s northern desert region, Chuquicamata’s underground operation has sandier and finer soil than El Teniente.

A high-level executive, who asked not to be identified, said the PMCHS management team had made mistakes due to overconfidence in their experience of underground mining at El Teniente.

Reuters‘ request to interview the local mine manager was denied.

The workers told the news agency that maintenance had been “completely abandoned” in the mine. They described a dearth of spare parts and a lack of back-up systems, meaning many malfunctions completely halt operations.

One worker told Reuters during a December trip to Calama in northern Chile, where the mine is based, that some machines that were supposed to be retired in 2019 were still in use.

The worker said only four of the mine’s 10 large mining trucks are operational due to failure or maintenance and machinery frequently breaks down due to the abundance of fine material.

The worker said two belts should be moving 11,000 metric tons of material a day but haven’t been able to move more than 6,000 tons.

Reuters could not verify this information independently.

A previously unreported 2023 sanction by government regulator Sernageomin, reviewed by Reuters, said a serious tunnel collapse in Chuqui was caused by major construction changes that weren’t submitted for approval by the regulator.

The report says the company used fewer, weaker rebars that were spaced further apart than originally planned. It also replaced steel frames with insufficiently stable retaining walls.

The report pointed to five previous “collapses or landslides” in 2020 that showed changes made by the company were major and inefficient.

Pacheco did not comment on the specifics of the report and the company did not reply to further questions on the investigations.

Structural projects: from savior to burden

All four of Codelco’s megaprojects have been delayed by years, faced cost overruns totaling billions and suffered accidents and operational problems while failing to deliver the promised boost in production, according to the company’s own projections.

Codelco hands over its profits to the state and the company has often complained that this has hampered its investment abilities and led to its debt problems.

Juan Carlos Guajardo, head of the consultancy Plusmining in Santiago, said that while mining projects are rarely finished on time and on budget, Codelco “has had some significant strategic errors,” especially attempting simultaneous projects.

One of the other megaprojects is expanding El Teniente. An 8-kilometer tunnel that aims to expand the mine’s life by 50 years was supposed to go live in 2017. It was advancing at about half a meter a day with 500 meters of tunnel left to go, then-CEO Andre Sougarret said in August.

The expansion, done with explosives, generated unexpected seismic events due to built-up pressure from rock blasts.

A 2021 report by regulator Sernageomin, reviewed by Reuters, showed that the tunnel fortification wasn’t strong enough to withstand blasts it was designed for.

The previously unreported document says the tunnel was designed to withstand a 1.9 Magnitude (Mw) event, but a tunnel roof and sidewall collapsed during a 1.7Mw event on Sept. 26, 2020. The report noted there’s a high chance such events would continue happening.

In July, a seismic event caused by a rock blast led to a collapse that left one worker temporarily trapped. Twelve others were evaluated at health centers but with no serious injuries.

In response, Codelco said it was preparing a report by the end of the year investigating the cause and analyzing measures to improve fortification systems. The report has yet to be published.

“If it’s complex to do one megaproject, it’s a lot more complex to do four simultaneously,” Pacheco said, adding that the projects were already well underway by the time he took over. “We would have preferred to do them successively.”

(By Fabian Cambero and Alexander Villegas; Editing by Christian Plumb and Claudia Parsons)

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments

Eduardo Esteffan M

Excelente información fundamentada