General Motors digs into mining business to lead race for EV metals

General Motors is trying to speed ahead in the race for metals underpinning the industry’s shift to electric cars.

The US automaker is competing for a stake in Vale’s base metals unit, people familiar with the matter said this month. A deal may give GM access to the Brazilian mining giant’s copper and nickel resources that are key to making EV batteries.

GM has made several such wagers recently, buying equity while rivals mostly sign supply deals. Last month, it bought a $650 million stake in Lithium Americas to help develop Nevada’s Thacker Pass mine, which may support output of as many as 1 million EVs a year. In October, GM invested $69 million in Australia’s Queensland Pacific Metals, a producer of nickel and cobalt. The moves are strategic bets to secure supplies that are getting increasingly sought-after.

“We’ll continue to work with many people in the industry, especially in lithium and the other critical minerals,” CEO Mary Barra said in an interview with Bloomberg Television in New York on Thursday. “I think we’ll be positioned to have a competitive advantage.”

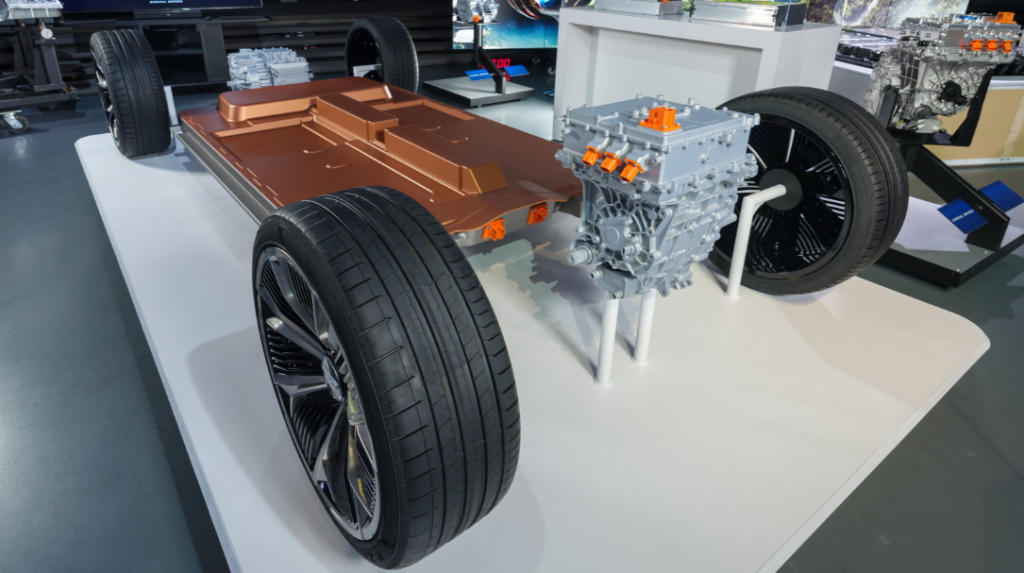

GM is pledging to sell nothing but plug-in models by the middle of the next decade. The Detroit automaker has opted to build its own battery pack and dedicated EV platform rather than move quick with converted internal combustion hardware, slowing its initial electric push. Still, Barra said that output of EV models such as the Hummer pickup, electric Cadillac Lyriq, Chevrolet Silverado pickup and Blazer SUV will ramp up this year.

Securing stable battery-metal supplies would be a boon — especially given the sector’s volatility. Cobalt prices, for example, rallied sharply last year but have since come crashing down amid a sharp drop-off in purchasing from the Chinese electronics sector. Nickel briefly soared to over $100,000 a ton in March before ending the year under $30,000. Lithium became so expensive last year that Chinese factories that typically make ceramics for bathroom tiles produced the EV battery material instead.

GM is part of a bigger trend. Automakers including Ford have signed long-term mineral supply deals. Germany’s Volkswagen last year agreed to form a €3 billion joint venture with Belgium’s s Umicore for cathode materials. In 2021, Tesla struck a nickel deal with BHP Group and a cobalt pact with Glencore, and in March that year got involved in a mining venture in New Caledonia.

Those deals may also help the miners. Barra said GM can provide them with additional cash and will be a stable source of demand thanks to its target to sell 1 million EVs in 2025, and many more beyond that.

The industry may want to tread carefully. Amnesty International has warned that mining is linked to environmental issues and claims of human rights abuses. In an era when environmental, social and governance shortcomings carry severe reputational risks, GM could be exposing itself to criticism.

Vale faced criticism after the collapse of the Brumadinho dam in Brazil, which killed 270 people and released toxic sludge into the environment. The accident caused Vale to lose its position as the biggest iron-ore producer and sparked a company-wide safety and governance overhaul. Reparations continued to take the shine off its financial results years after the incident.

Several companies are looking for ways to reduce the environmental footprint of mining to minimize those ESG concerns. GM has invested in Controlled Thermal Resources, a startup working to extract lithium using renewable energy, and is backing Lithion, a Canadian startup that recycles EV batteries to reuse materials.

Despite its mining foray, GM has some catching up to do on EVs. The Detroit automaker sold just under 40,000 EVs last year, finishing behind Ford and far short of market leader Tesla. Barra vowed the company is just getting started, including with Chevrolet’s Equinox and Blazer models coming out this year, which start at around $30,000 and $40,000 to $45,000, respectively.

“These are very affordable vehicles,” the CEO said. “There is going to be a huge opportunity to sell a lot of them.”

(By David Welch)

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments

W

I do so hope, that Mary Barra, and her GM Board, have got a ..LOT, of patience, AND, ..TIME, to wait, while she’s ..waiting, for her GM ..’investments’, into all of these ..new, ..startup Lithium Mining ..’hopefuls’ to ..start, bearing fruit, for her, and for the GM company, because ..actually ..getting ..affordable, Lithium Production, out of any, new mine, takes anywhere between 3 years, at the earliest, and typically, 10 years, or even longer, at worst case, and in that time, the Chinese EV Auto makers ..won’t, just all just be sitting around and picking their noses and ..wasting, their own country’s, current, 20 years long ..lead, upon the West, in their manufacturing of Lithium Batteries, and, the EVs, powered by them…!! ???