Five levels of minerals processing plant autonomy – from regulatory controls to full auto-pilot

How do you automate the minerals processing plant? It is not a very easy question to answer, partly because many look at it as an all-or-nothing endeavor. This could not be further from the truth though, there are multiple levels and phases that mining operators go through. Making sense of the possibilities is a great first step.

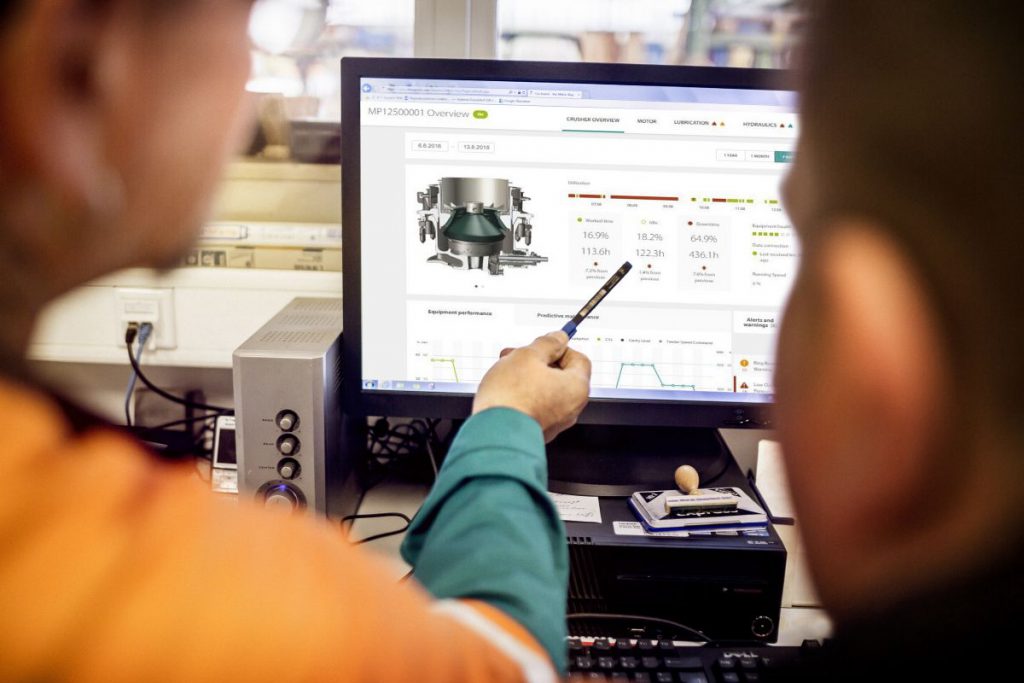

Autonomous mining is already here

Autonomous is a big thing currently not only in the automotive industry, but also in other industries including mining. Autonomous haul trucks have existed in mines already for quite some time, actually well before Google Cars were even imagined. Since then, we have also seen the introduction of autonomous drill rigs, loaders, and lately also the “biggest robot in the world” running on rails launched by Rio Tinto.

Introducing autonomy to the mining process provides many advantages. A huge benefit is increased safety, as more people can be removed from underground and other hazardous places to instead run the daily operations from a clean and safe control room. A second benefit is productivity, as more trivial tasks are automated hence freeing up people to do higher level planning and optimization work.

Levels of autonomy – from cars to processing plants

When it comes to vehicles, five levels of autonomy have already been clearly defined. At lowest level of autonomy, level 1, we see automation like cruise control, where the automation does a single task and always requires human supervision. On highest level, level 5, the vehicle is fully autonomous and no human intervention of any kind is required, allowing even the steering wheel to be removed.

Interestingly, in minerals processing, there is no generally accepted framework for the different levels of autonomy of the plant. At the outset, it may seem that such a classification would be unnecessary, since the plants are fixed and – unlike cars and other mobile equipment – do not move around.

However, the situation is quite the contrary and classification of autonomy levels would be needed. Today, minerals processing plants require constant daily intervention by humans to adapt to changes in plant feed, disturbances in operating conditions, and degrading equipment health. These plants can easily employ hundreds of people whose daily job is to monitor the process and the plant, and to take care of maintenance activities. At a fully autonomous plant, such an army of people would not be necessary or at least their role would be very different. Between the two extremes, clearly there must be levels of increasing autonomy…

Read the entire article on metso.com: Five levels of minerals processing plant autonomy – From regulatory controls to full auto-pilot

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments