Energy crisis, bottlenecks blunt metal rally windfall for miners

Soaring metal prices should mean surging profits for mining companies, but they are the result of energy shortages and logistics bottlenecks that are also pushing up costs for producers.

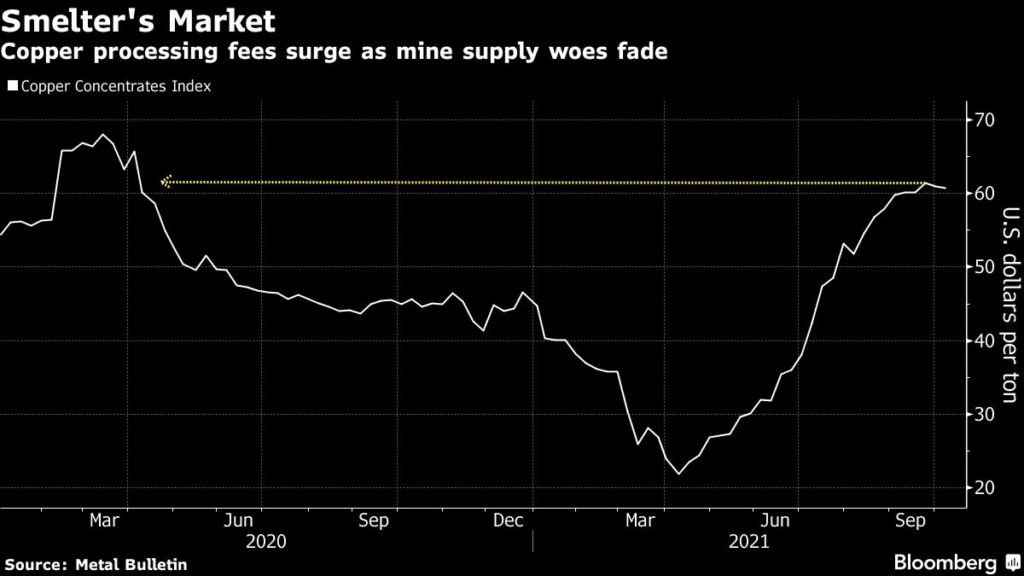

The latest leg-up in copper and zinc futures is coming on the heels of a global energy crunch that’s beginning to disrupt the smelters that many miners depend on to process what they pull out of the ground. That’s great for refined metal prices but suggests further hikes in smelting and refining fees already at the highest levels since early in the pandemic.

RELATED: Copper price tops $10,000 as energy crisis hits supply

For companies like Hong Kong-listed MMG Ltd. that ship mainly semi-processed metal called concentrates, those higher treatment fees blunt the boon from elevated metal prices. On the other hand, producers with plenty of in-house smelting capacity — like Chile’s Codelco and Poland’s KGHM Polska Miedz SA — are less vulnerable.

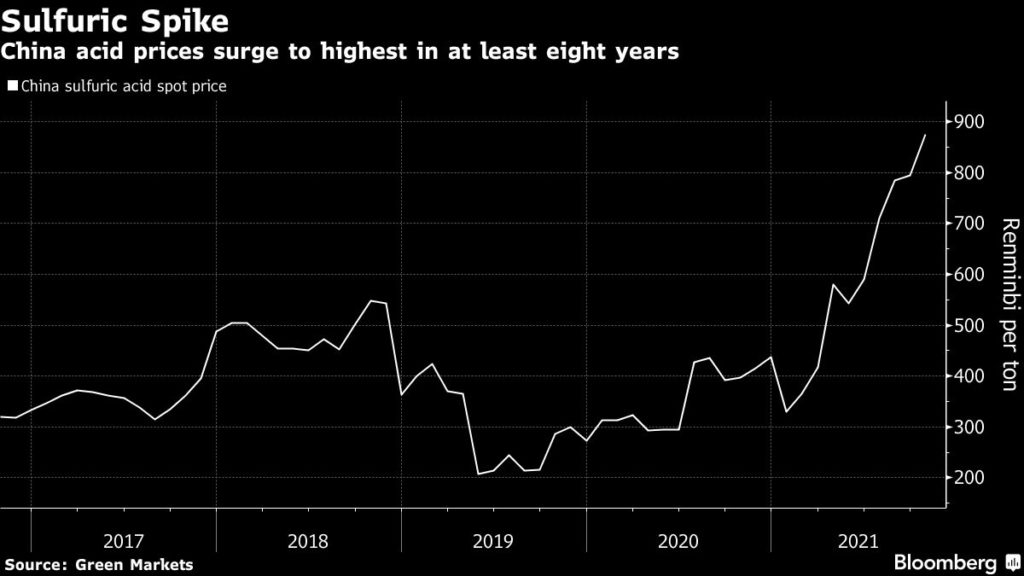

Another impact from logistical disruptions and inflation is a global squeeze on sulfuric acid used in some mining operations, with prices at their highest since at least 2013.

While some smelters produce sulfuric acid as a byproduct, the solvent extraction-electrowinning technology that’s widely employed in Chile uses it as a feedstock. That makes the Chilean mining industry one of the most intensive sulfuric acid users.

To be sure, the extent of the metal rally probably more than offsets those cost increases for most miners. But the industry will be paying close attention to energy markets over the coming months for signs of further tightening.

(By James Attwood)

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments