Efficient thermal processing for versatile industries

Thermal processing of bulk material is tricky. Certain moisture levels can make materials difficult to ship, but processing methods can contaminate or negatively affect the material. An easy solution to this problem is the Metso Holo-Flite®. The Holo-Flite has been around for over 60 years, but what exactly does it do? Throughout its decades-long history, this machine has solved customer challenges in numerous industries. So, what can the versatile Holo-Flite do for you?

Direct vs. indirect heat exchange in solving material moisture level challenges

Thermal processing can be done in two different ways, direct or indirect heat exchange. With direct heat exchange, heat comes in direct contact with your product, which can contaminate the material. In addition, the heat cannot be recycled, which reduces thermal efficiency.

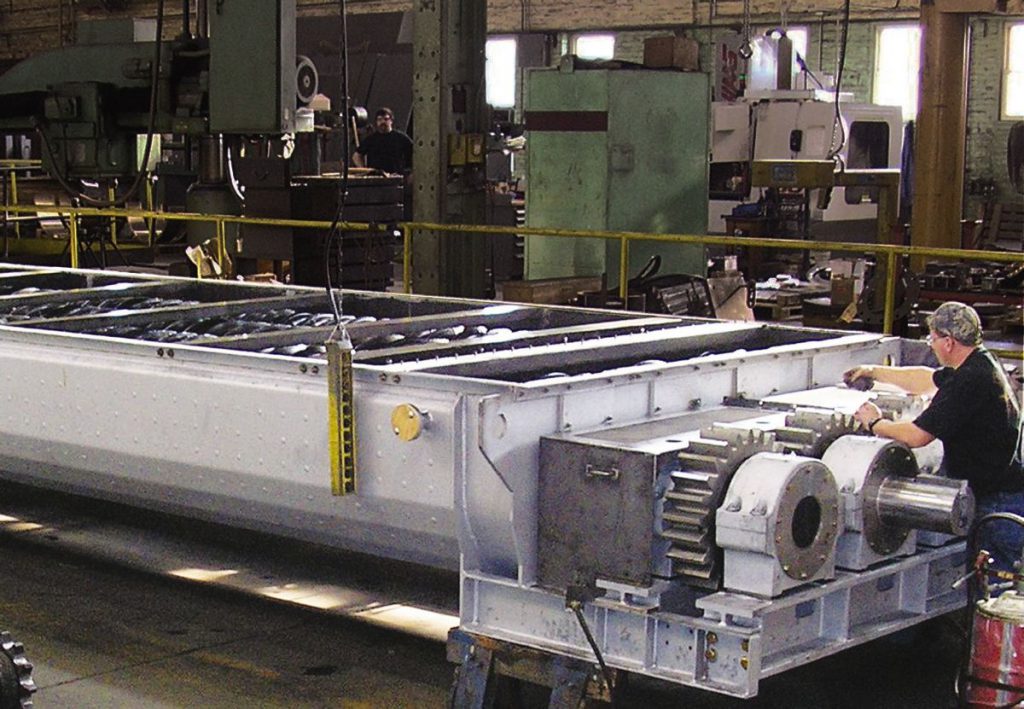

The Holo-Flite uses indirect heat exchange which can be either a heating or cooling process. During this process, a heat transfer medium is circulated through the cavities of the machine’s screws and trough for better temperature control, minimized dust, and the ability to recycle heat, which means less risk for product contamination.

Within the machine, individual particles are heated, cooled, or dried as the product is continuously conveyed by means of rotating screw flights along a jacketed trough.

Both heat exchange methods have their benefits and challenges, but with indirect heat exchange, you gain more efficiency for less wasted product.

Greater efficiency, less product degradation, less costs – Benefits of the Holo-Flite

If one of your jobsite challenges is managing leftover ores that cannot be shipped due to retained moisture levels, indirect heat exchange is an easy solution.

The Holo-Flite can dry very fine materials using indirect heat exchange in addition to regulating moisture levels to ensure end product quality. Because the Holo-Flite recycles heat, heat is in constant contact with the material, and airborne heat loss is minimized for greater efficiency. The operator of the Holo-Flite has complete control over the temperature as well as screw speed. Controlling the screw speed allows for less product degradation, minimal dust generation, and low maintenance costs…

Read the entire article on metso.com: Efficient thermal processing for versatile industries.

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments