An abundance of aluminium scrap to spur US recyclers

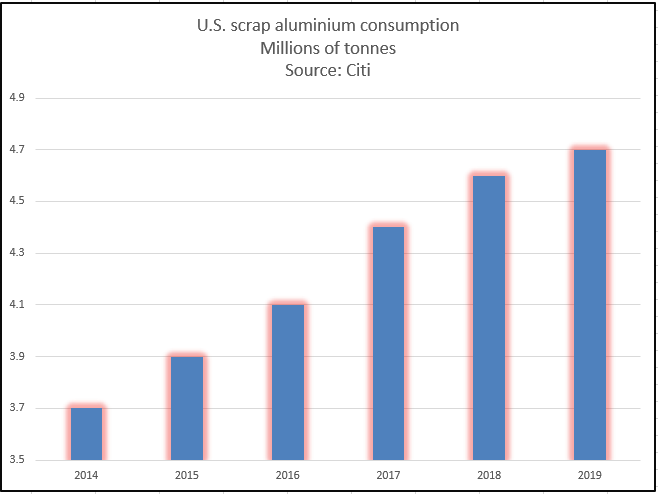

The growing use of aluminium by transport and packaging firms in the United States has created an abundance of scrap and is encouraging recyclers to expand capacity in what industry analysts see as the start of a new trend.

Those already expanding include Novelis, one of the world’s largest producers of rolled aluminium products, which last month announced plans to invest $36 million to boost and upgrade recycling capacity at its Greensboro facility in the United States, to be completed during the second half of 2021.

Canada-based Matalco is also planning a new $80 million aluminium recycling facility in Wisconsin while JW Aluminium is expanding its facility in Goose Creek in South Carolina at a cost of $255 million.

The United States has a 10% levy on imports of primary aluminium, but not on scrap, where prices have plummeted

“Scrap buyers are struggling to take more, investment is needed,” said Citi analyst Oliver Nugent. “If you think the tariffs on primary aluminium are here to stay then it makes sense to think about alternatives like scrap.”

The United States has a 10% levy on imports of primary aluminium, but not on scrap, where prices have plummeted.

A proxy for auto scrap is the LME’s aluminium alloy contract which fell by more than half to $1,000 a tonne in October from above $2,000 in April 2018. It is now at $1,230.

“Scrap prices are heavily discounted because availability has outpaced capacity and because tariffs exempt scrap,” said Jorge Vasquez, founder of consultancy Harbor Aluminium.

Harbor estimates beverage can scrap prices at nearly $900 a tonne below the London Metal Exchange’s benchmark primary aluminium at around $1,760 a tonne.

It also reckons the United States generated 5.9 million tonnes of scrap aluminium last year, up about 20% since 2016. Of that about 5 million tonnes was recycled domestically, while the rest was exported.

Valued for its lightness and anti-corrosive properties, demand for aluminium from U.S. drinks firms is expected to rise over coming years as they come under pressure to cut plastic pollution.

In autos, the advent of electric vehicles powered by batteries and the need to reduce the weight of the car are expected to see aluminium use increase.

Data from the Aluminium Association shows aluminium use in passenger cars and light trucks climbed 23% to 6,080 million lbs between 2007 and 2017. Overall, aluminium use in transport rose nearly 20% to 9,625 million lbs in the same period.

“To truly benefit from the circularity of aluminium requires improvements in collection, sorting and processing methods of post-consumer scrap,” said Wood Mackenzie analyst Kamil Wlazly.

“Producing aluminium uses a lot of energy, but it can be recycled infinitely. Aluminium scrap is the future.”

Electricity can account for between 30% and 50% of the costs of producing aluminium, depending on whether it is generated using coal, gas or hydro power. Energy costs of recycling aluminium are typically about 5% of producing primary metal.

Total aluminium consumption in the United States this year is estimated at more than 10 million tonnes, nearly 15% of the global total at 67 million tonnes.

(By Pratima Desai; Editing by Emelia Sithole-Matarise)

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments