Albemarle windfall shows lithium’s resilience to recession fears

The lithium boom is proving so resilient amid recession fears that the world’s biggest producer now expects its operating cash flow to outweigh total expenditures for the first time in six years.

On Wednesday, Albemarle Corp. reported higher-than-expected second-quarter profit and lifted its annual guidance beyond analyst estimates. The brighter outlook means it now expects to be free cash flow positive in 2022, while consensus is for it to stay negative to the tune of more than $500 million. Shares reversed an early gain to fall 1.9% in New York.

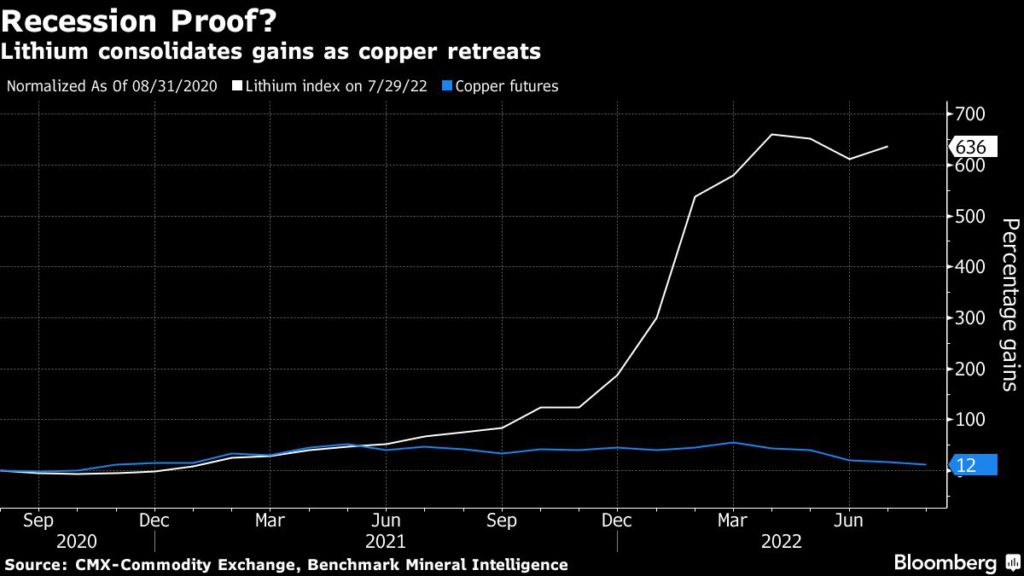

Albemarle is cashing in on soaring demand for a key raw material in powering electric cars. As other metals with a broader share in older industries, like copper, wilt under the weight of slowdown concerns, lithium prices are holding up. That’s allowing producers to lock in sky-high prices in contract renewals, cushioning the blow of higher costs.

The Charlotte, North Carolina-based company will continue to bring on new facilities to process mined lithium into chemicals needed for batteries, with a goal of as much as 500,000 tons in annual capacity by 2030, according to chief financial officer Scott Tozier.

The Americas hosts diverse lithium reserves — from brine in Chile, Argentina and Bolivia, to hard rock reserves in the US and Canada, to unconventional reserves such as oilfield brine and clay in the US. The prospects are “very good” for an increase in lithium refining capacity in the region as “each reserve needs conversion facility in order to take the raw material and turn it into the lithium carbonate or lithium hydroxide chemical that’s required for batteries,” he said.

While Chile and Australia account for the majority of global lithium mine supply, China has more than half of all capacity for refining it into specialist battery chemicals. There are also growing concerns over the Asian nation’s dominance of refining and manufacturing capacity of the material as reliance on China is now seen as a vulnerability amid trade and political tensions that are spurring a rethink of global supply lines.

Elon Musk in late July called for more investment in global lithium refining to ease shortages in battery materials — and promised those who seize the opportunity it’s as lucrative as “basically minting money.”

China is the least-expensive place to process lithium, due to lower construction costs and a large processed chemistry engineering base to tap into, according to Tozier. By comparison, it costs twice as much to build refining capacity in Australia and the US, while South America is somewhere in between, he said.

(By James Attwood and Yvonne Yue Li)

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments