A $91 billion trade means mining in one of the world’s hottest places

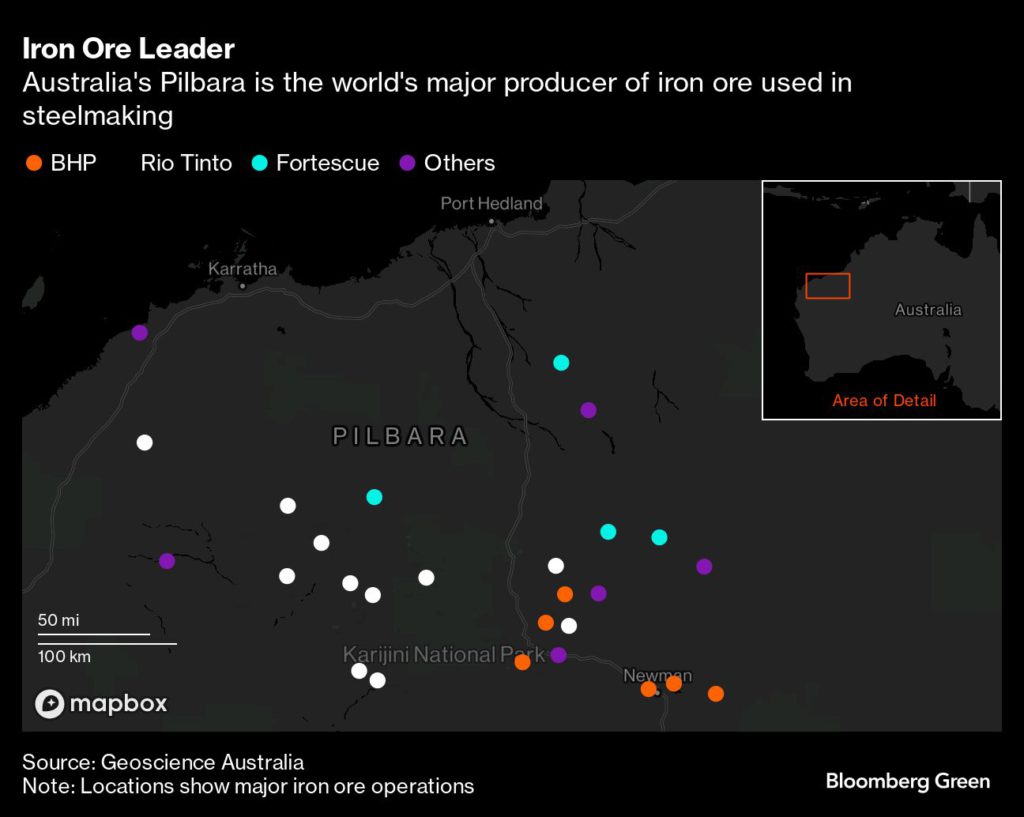

Snaking through the russet-colored expanse of Australia’s remote Outback, vast mile-long trains ferry iron ore — the nation’s most valuable export — across a crucial mining district that’s increasingly vulnerable to volatile weather and where temperatures have matched the Southern Hemisphere’s record of 50.7C (123F).

Heatwaves during the country’s most recent summer set new extremes across the Pilbara region, roughly the size of Spain. That has challenged a workforce of more than 60,000, many of whom operate outdoors in a network of dozens of open pits, process plants, railroads and ports. Conditions, according to the miners, are often like stepping inside an oven.

On Dec. 30, heat touched 49.3C in Marble Bar – equaling the highest recorded in the desert town in 122 years of observations by Australia’s meteorological service – and that day, an iron ore rail line nearby buckled under the stress, causing a Fortescue Ltd. train to slip from the tracks, scattering ore cars. While the crew were uninjured, the exporter’s railroad was disrupted for four days.

Metals and natural gas producers in the Pilbara and the region’s communities, including Aboriginal Australians with a local history stretching back at least 40,000 years, have long managed weather risks, contending with tropical cyclones that menace the northwestern coast, regular bushfires and flash floods.

Preparing for a future of elevated climate change-fueled threats is vital to protect an iron ore industry that’s prospered for decades by supplying steelmaking materials to mills in China and across Asia, a trade that underpins Australia’s economy and was worth about A$138 billion ($91 billion) in export earnings in the year ended June 30.

“It can be a relentless environment,” said Matthew Holcz, managing director for Rio Tinto Group’s Pilbara mines. “When we look at global warming under a whole range of different scenarios – in terms of carbon emissions – those periods of extreme temperatures could be even more prolonged.”

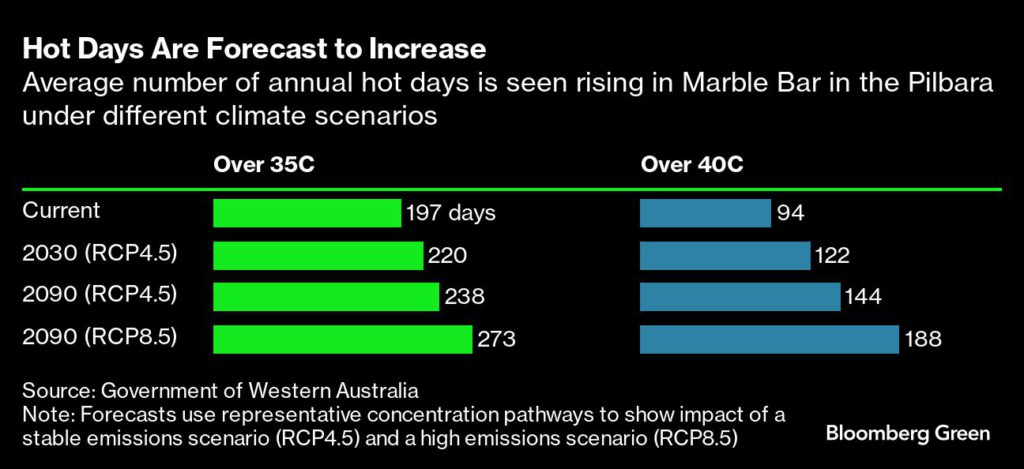

London-based Rio forecasts that, under a pessimistic global emissions scenario, its Gudai-Darri operation, about 1,095 kilometers (680 miles) northeast of Perth, will see the number of days above 40C double to 80 a year by mid-century and exacerbate concerns around employee health and the reliability of power sources and electricity infrastructure.

BHP Group Ltd., the most valuable global mining company, predicts the number of days topping 40C in the eastern Pilbara could rise to 124 a year in the 2070s from about 54 currently. A review of the likely effects on more than 140 pieces of equipment found that outcome would pose new challenges to items including transmission cables and road surfaces.

While those assessments peer decades into the future, the potential impacts are relevant now to commodities producers that are investing billions of dollars in mining sites often intended to operate for 40 years or more. Australia’s largest iron ore suppliers, including Rio, BHP and Fortescue, have spent about $16 billion on new Pilbara projects in the past decade.

The proportion of BHP’s global assets at risk from heatwaves will rise to 96% by mid-century from about three-quarters in 2030, according to data on the exposure of physical assets to climate change compiled by Bloomberg. Rio’s exposure will climb to 88% from 79% over the same time period, the data show.

Temperatures already have an impact for large miners, not only in Australia’s sweltering pits but in other arid locations that host valuable metal resources, like Chile’s Atacama Desert. About 2% of reported occupational illnesses at BHP involve heat stress, the company said. In some isolated cases in the industry, the issue has contributed to fatalities.

“It’s like a wall of heat whenever you walk outside,” said Shane Roulstone, national mining organizer at the Australian Workers’ Union, and who has spent time on sites across the Pilbara over the past decade. “When you’re that hot and exhausted, mistakes happen and workers are at risk.”

A 49-year-old exploration field technician working for Rio died in October 2017 after collapsing during a search for new drilling sites in the Pilbara, according to Western Australia’s Department of Energy, Mines, Industry Regulation and Safety. The man and two colleagues had been required to walk distances of more than 16 kilometers a day in temperatures that likely topped 37C and didn’t understand they were required to carry out heat stress assessments.

Rio was fined A$80,000 in 2021 in connection with the incident, over a failure to ensure employee safety. The miner had heat policies in place at the time, and has continued to develop its response to extreme temperatures. Staff carrying out high heat-risk tasks are monitored daily for signs of illness, while those exposed to some hot environments undergo a period of acclimatization before commencing work, Rio said in an annual report published in February.

At Pilbara mine sites, there are cool zones close to working areas and processes to ensure there’s adequate hydration and extra breaks for staff, according to Rio’s Holcz. “We also schedule more physically taxing work at night, or make sure we can do more in our workshops which, if not air conditioned, will at least have fans and are out of direct sunlight,” he said.

Fortescue has measures in place including temperature sensors across its 760 kilometers of railroad and is evaluating technologies to monitor workers’ hydration, like saliva testing, the company said.

Even with those challenges, the mining industry is continuing to expand in some of the most heat-prone areas. Onslow on the Pilbara’s coast recorded the Southern Hemisphere’s hottest-ever temperature in January 2022, matching the level set in 1960 in Oodnadatta, South Australia.

In May, Mineral Resources Ltd. began exports from a new iron ore mine on Onslow’s outskirts. The site is expected to operate for at least 30 more years.

(By Paul-Alain Hunt)

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

2 Comments

Fologang Mogotsi

Please we have iron ore in Botswana,we need investors, feasibility reports are ready

Geoffrey Githui

I like to hear more