ME FIT: Fully Integrated Technology from ME Elecmetal

There is an increasing demand in the mining industry for new technology capable of optimizing processes, equipment and performance. ME Elecmetal believes there is always room for improvement. We focus on delivering tailor-made technology solutions for grinding and crushing applications, with a complete offering of optimization tools.

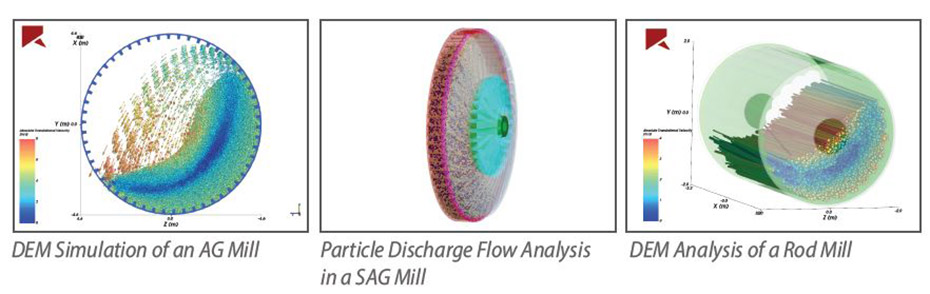

3D DEM Suite

DEM (Discrete Element Modeling) simulations have become an essential tool in the design and optimization of equipment used in grinding and crushing. ME Elecmetal’s DEM simulation software tools allow our customers to better understand the downstream effects of liner design changes. Our 3D simulations and virtual mill and crusher models help quantify solutions for operational challenges related to crushing and grinding; providing energy utilization, power consumption, tons processed and impact force, among others.

2D DEM Simulations

DEM simulations in two dimensions are also available to our customers. These types of simulations are useful when customers require data sooner, or for less complex situations.

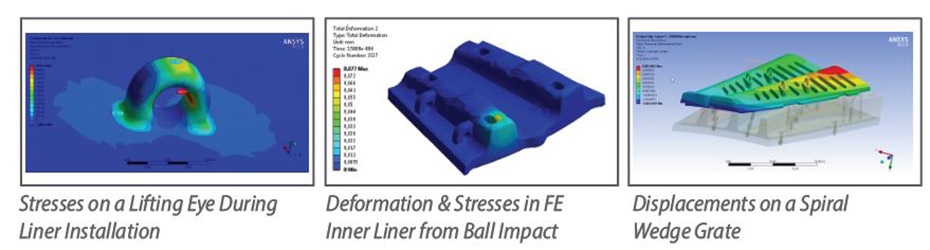

FEA Simulations

The use of FEA (Finite Element Analysis) simulations is widespread in industrial and engineering applications, especially in the field of mechanics where they are commonly employed to simulate strain, stress, force, displacement, velocity, acceleration, etc. ME Elecmetal’s FEA simulations make it possible to reproduce the mechanical behavior of both liners and the mill, under multiple operating conditions in order to avoid unwanted failures, optimize processes and components, and reduce the time required and risk factors associated with new product development.

ME Elecmetal Grinding Media Apps

ME Elecmetal Grinding Apps is a series of online applications developed to assist mineral processors in getting the most out of the grinding media used in their operations. You can access these tools online at: www.me-elecmetal.com

Wear & Performance Tracking

ME Elecmetal’s Wear & Performance Tracking reports provide historical operating parameters and liner wear profile data to help predict remaining liner life, compare current wear rates vs. historical wear rates and much more.

The measurement process utilizes 3D laser scanning technology which can measure up to one million data points per second and an ultrasonic device to measure liner thickness. Once the information is collected, it is uploaded to an electronic data base, then a timely report is generated converting data into information enabling our customers to make informed maintenance and operational decisions.

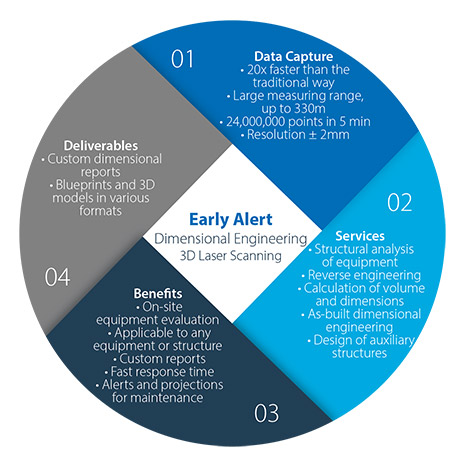

Early Alert Service

Early alert service provides monitoring of mining equipment conditions through nondestructive and highly specialized technology such as 3D laser scanner metrology, vibration analysis and ultrasonic imaging (phased array).

The 3D laser scanner can measure up to one million points per second. The point cloud is then processed with specialized software that produces a 3D image of the scanned equipment which is used to analyze liner wear profiles, remaining thickness, etc.

Predictive and symptomatic maintenance consists of conducting an analysis of the operational and structural status of equipment to determine what corrective actions must be taken to enable the equipment’s operational continuity in the event of a failure.

For more information, visit www.me-elecmetal.com or call 480-730-7500.

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments