Improve Efficiency in the First Stage of Ore Comminution

ME FIT Crushing takes the entire implementation cycle into consideration in its technical proposals: manufacturing, installation, deployment and performance monitoring. We believe continuous communication with our customers is key to understanding their entire process, so we are better able to detect anomalies and propose modifications with a focus on continuous process improvement.

Because ME Elecmetal understands the day-to-day complexities of a crushing operation, we can rapidly respond to the needs and unique challenges our customers face. This enables us to provide solutions to positively impact priority KPIs: tons per hour, safety management, availability and maintainability of equipment, risk prevention, among others. We measure the value of a solution based on its impact on our customer’s entire process — in line with their priorities and operational strategies.

Products and Services that Create Value

The ME FIT Crushing program focuses on improving efficiency in the first stage of ore comminution, reducing processing costs and optimizing crushing equipment availability and reliability.

To do this, we design solutions to help our customers achieve their goals by combining wear parts with technology tools, advice, training and monitoring — all of which allow us to create value in our customers’ processes.

Crusher Wear Parts and Safety Tooling

ME Elecmetal is the leader in offering wear solutions to crusher operators. We provide wear parts for primary, secondary and tertiary crushing applications for the mining, aggregate and recycle industries with optimal designs and alloys specifically developed for each application. We will help tackle any customer challenge, while striving to maximize the benefits we provide. We can adapt to any type of equipment customers may have on site.

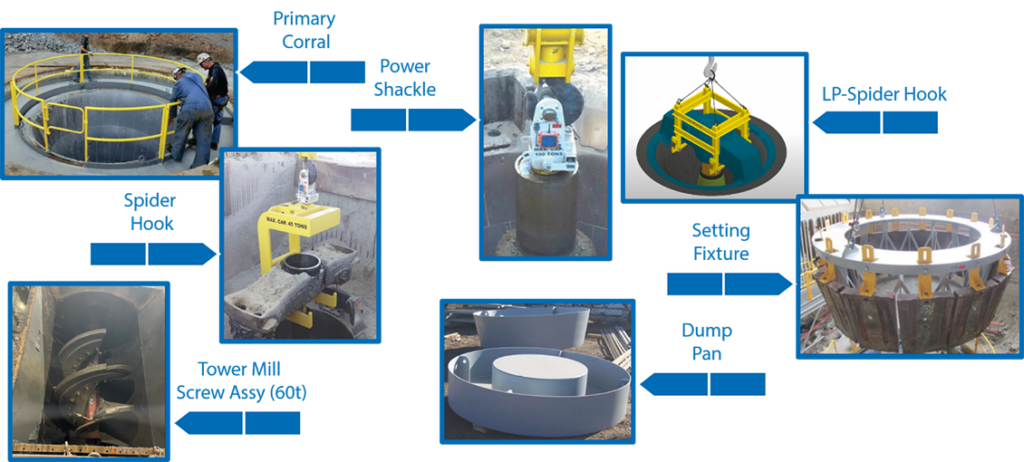

With a focus on safety, durability and ease-of-use, ME Elecmetal also offers a full line of Crusher Safety Tooling products designed to help you get the job done safer, faster and smarter! Our products include:

- Primary Corrals

- Dump Pans

- Setting Fixtures

- Crusher Nuts

- Power Shackles

- Spider Hooks

- Custom Solutions

Continuous Improvement

Through new technologies, proprietary product designs and manufacturing, we help our customers achieve better crushing solutions, thus streamlining production, availability, reliability and quality, while ensuring we are able to adapt to and solve any problems that our customers may encounter.

Our Method:

- Detect opportunities within a process

- Diagnose the analyzed situation

- Compare findings with the customer’s needs

Generate the best, cost-effective solution

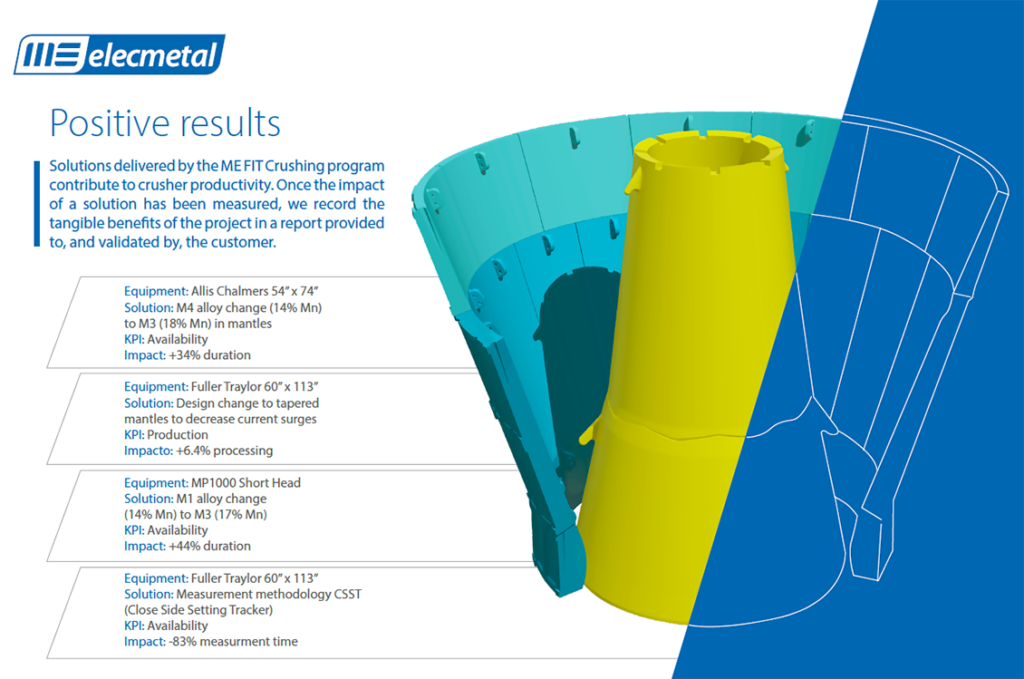

Positive Results

Solutions delivered by the ME FIT Crushing program contribute to crusher productivity. Once the impact of a solution has been measured, we record the tangible benefits of the project in a report provided to the customer.

Innovation through Experience and Technical Knowledge

The ME FIT Crushing program evolves with the needs of our customers and the adoption of technology. With the development of digital tools for capturing and analyzing large volumes of data, ME FIT Crushing solutions allow increasingly accurate projections to be made and assists in the creation of specific solutions to address unique challenges. We are constantly learning new technologies so that we may better support our customers. Our experience proves we are qualified as a technology partner that sees beyond the main challenges and strives to exceed customer expectations.

Mutual Collaboration Builds Trust

ME FIT program solutions are possible because of the mutual collaboration between our customers and the ME Elecmetal technical team. The knowledge and deep understanding of the unique challenges at each mining operation help us provide crushing solutions that have a positive impact priority KPIs. We align with the priorities of our customers, positioning ME Elecmetal as a true strategic partner in mining.

Contact Us Today!

For more information on ME FIT Grinding Crushing and to learn more about how ME Elecmetal can help you optimize your comminution processes, visit www.me-elecmetal.com or call 480-730-7500.

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments