Customized Grinding Mill Liner Solutions

There are many important factors that determine the performance of wear parts and liners in a grinding mill, two key factors are the materials they are made from and their design. At ME Elecmetal, we analyze our customers’ applications to determine the ideal combination of design and materials to achieve the optimal wear performance and throughput for their equipment, whether it is an AG, SAG, Ball, Rod or Tower mill.

Our liner designs and materials are developed to deliver maximum wear life and throughput in both high impact and high abrasion applications, regardless of the type of mill. ME Elecmetal offers a wide range of complementary services including condition monitoring to further improve efficiency and provide our customers with real time information.

ME Elecmetal is always working on the next generation of alloys to increase wear performance and grind efficiency. We analyze our customer’s operating conditions, and cross reference that information with our global knowledge base end their production goals, to develop an optimized solution. Then, we work in step with our customers to implement and validate our solution.

ME Elecmetal works closely with operators and plant maintenance crews to monitor wear performance and production rates, customizing each liner for the best possible performance. All variables are considered in this analysis – from the characteristics of the ore and the customer’s operative strategies, to their production goals.

ME Elecmetal’s innovative material and liner designs deliver proven, world class performance, while minimizing costly reline and downtime. Our wear parts are manufactured according to the highest quality standards and state-of-the-art technology and engineering, resulting in the most reliable lowest total-cost-of ownership-solutions for our customers.

ME FIT System® : Fully Integrated Technology from ME Elecmetal

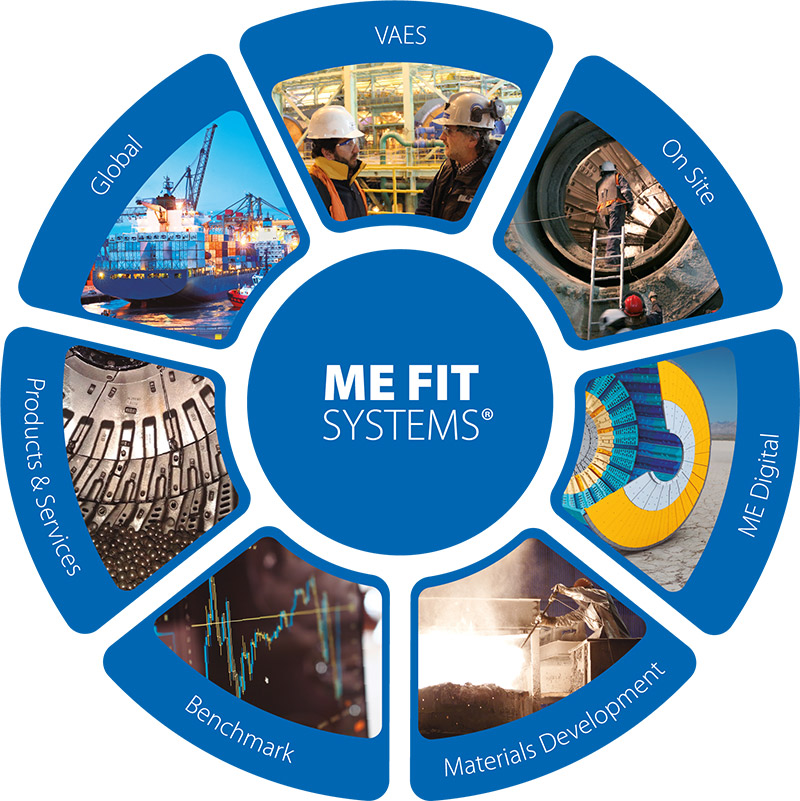

ME Elecmetal’s delivers integral solutions for grinding and crushing applications through our ME FIT System® offering. FIT stands for Fully Integrated Technology. The system involves a team approach to examine customer needs and develop customized solutions that address specific challenges and add demonstrable value to our customers’ operations.

The system takes advantage of ME Elecmetal’s highest standards in quality, manufacturing, service and logistics along with the multidisciplinary team who bring it all together.

We become a partner to our customers by understanding their needs. To accomplish this, we collect operational data including processed tonnage, available power, down time, load levels and all other relevant information about how their mills operate. We measure how long media and liners last, what production levels they are achieving and what opportunities there are for improvement in their comminution process.

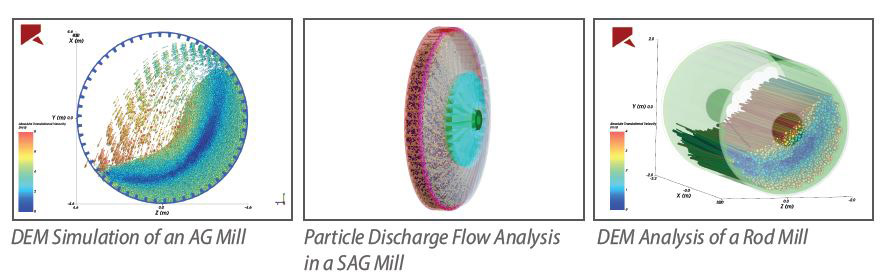

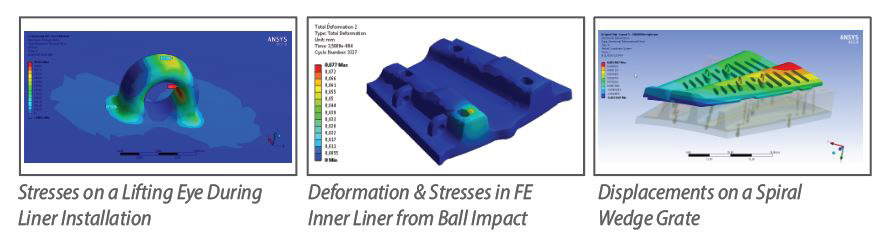

Changes introduced to processes in mining can affect both current and downstream operations. At ME Elecmetal, we understand that every decision made is absolutely critical. Before proposing changes to our customers, we run a series of simulations and tests, so we can be confident that the solutions we are developing will minimize any risks or adverse effects.

ME Elecmetal’s technical support and training goes above and beyond standard services offered by other suppliers. These services include DEM and FEM simulation services, 3D laser scanning for wear analysis, reline optimization, continuous improvement programs and grinding circuit optimization.

VAES Philosophy

VAES (Value-Added Engineering Services) is ME Elecmetal’s business philosophy. This benefits based sales philosophy is focused on providing our customers with comprehensive, value added solutions for ore processing which positively impact six key operational areas:

- Increased production

- Greater equipment availability

- Cost-effective solutions

- Environmental and health protection

- Safety (handling, management and storage)

- Training

As part of VAES, we record the tangible benefits of every project in a report provided to our customers. Through the VAES program, ME Elecmetal can help customers optimize processes, extend the lifespan of wear parts, reduce operational risks and increase profitability.

Earning the trust of our customers is our priority. We achieve this through proposing technical solutions that offer substantial benefits with minimal risks. At ME Elecmetal, we accept the responsibility of growing our credibility with the customer by integrating world class complementary products and services.

For more information, visit www.me-elecmetal.com or call 480-730-7500.

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments