Choosing replacement wear parts for your crusher? Start here.

If you are a crusher operator who must frequently replace wear parts, your focus is on getting the best value from the products you buy to remain competitive and profitable. Faced with operating costs that are increasing dramatically, it can be tempting to choose the cheapest option to meet recurring expenses. However, by selecting wear part replacement options that improve longevity, long-term costs can be reduced without compromising product throughput.

Keep in mind the following three questions as you begin your part replacement process:

How are wear parts designed for top performance?

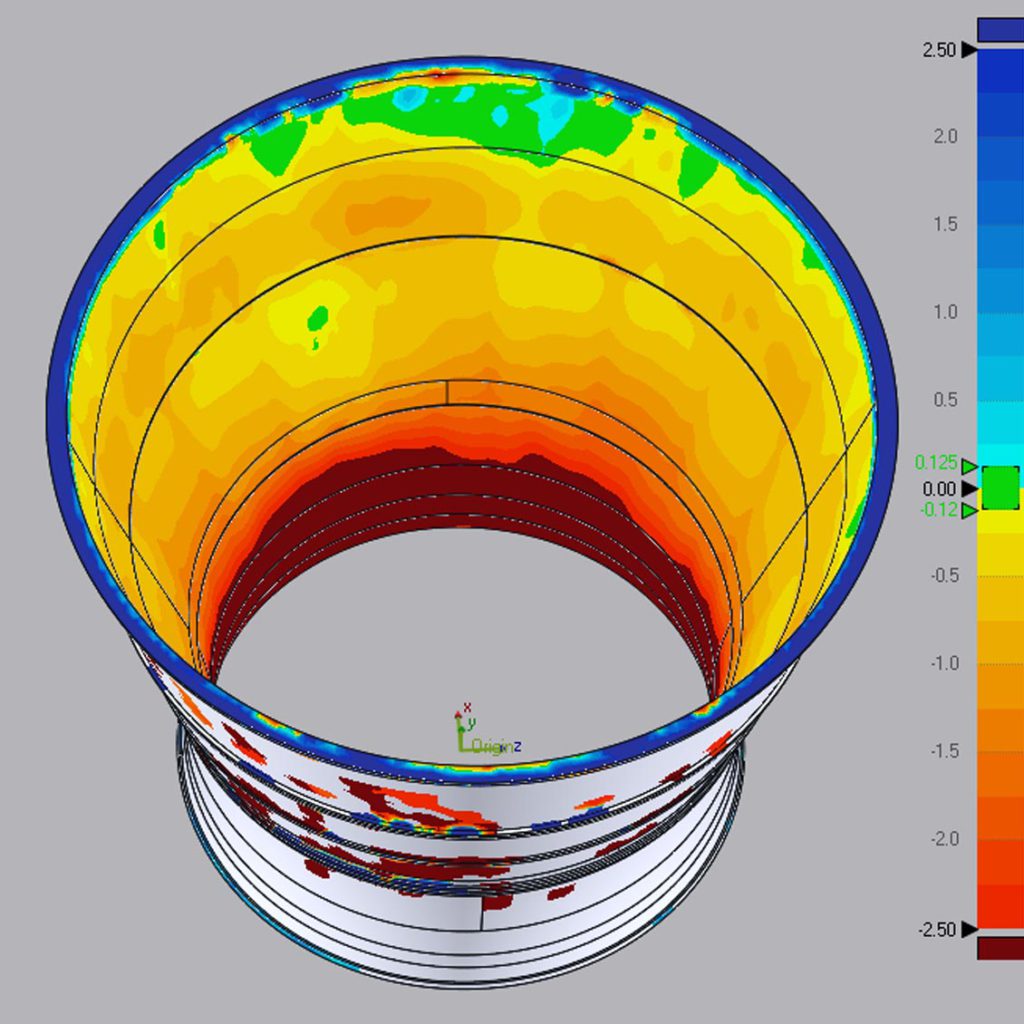

Because crushers wear in different ways depending on the type of feed material, its gradation, and discharge settings, a replacement wear part provider should conduct a wear analysis of your operation. Using laser technology, and/or “hands on” measurement methods of worn parts, Columbia Steel identifies the areas that take the most abuse. Based on this real life data, Columbia can engineer the liners to be thicker in critical wear areas to extend their service life. But it’s not enough to simply add more metal. Your vendor must also know how much material to add and where, without compromising the part’s profile and negatively affecting product throughput or gradation.

How your provider manufactures its products goes hand-in-hand with part quality as well. Most manufacturers charge by the pound, so a heavier, reinforced liner will be more expensive than a standard replacement part. But, if you budget a little more for a crusher liner that lasts longer without impacting the amount of product you produce, you’ll more than recoup that additional expense.

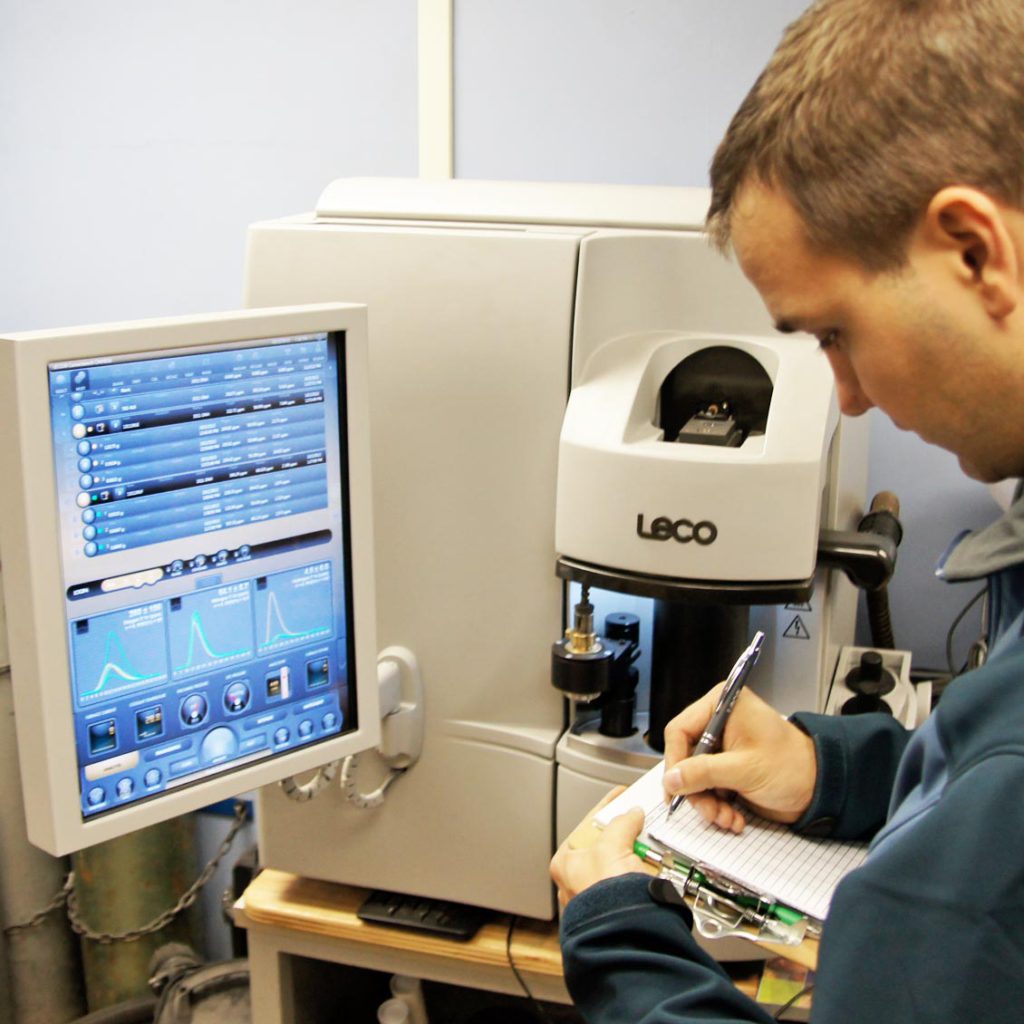

What options are available for manganese alloy content?

It’s well known that manganese steel alloy is incredibly tough, making it the perfect choice for high-impact crusher wear parts. However, not all manganese steel options are equal.

Beginning with an industry standard of 12% manganese alloy, some manufacturers can go up to an 18% or incrementally higher composition. In contrast, Columbia Steel offers the highest manganese alloy percentage on the market at 24% — which will outlast an 18% alloy in similar production situations. Columbia also adjusts other alloy components to maximize results. So when choosing your replacement parts vendor, do your research beforehand and ask how they create their alloy.

How well do you know the properties of the material you are crushing?

Manganese steel becomes harder as it deforms with repeated impact, a feature that makes it very effective in many crushing applications. However, manganese steel does not perform as well against highly abrasive materials that are softer or contain lots of silica. In these instances, the liner surface will wear away before it receives enough impact to work-harden.

So if you’re crushing a hard material, you’ll get better results by choosing a liner with a high manganese content. By contrast, when you’re crushing a more abrasive product, by using standard-grade steel you’re likely to get similar results, but without the added expense of premium manganese.

Customized solutions are the smart choice

The answers to these three questions reveal how vital customization is when choosing replacement wear parts. While original equipment manufacturer parts may be less expensive, they likely won’t be the best solution for your unique situation. That’s because rock type, throughput rates and product size all play a role in how crusher components wear and help determine the ideal replacement product. By strategically budgeting for a customized solution, you’ll get longer life and more value from your replacement wear parts.

About Columbia Steel – an American manufacturer

Our customers know there’s more to a Columbia Steel casting than just metal. Founded in 1901, our full service manufacturing facility puts our engineering and metallurgy know-how directly at your service, including:

- Casting Simulation Lab

- 126,800 sq. ft. Foundry

- On-site Pattern Shop

- 71,000 sq. ft. Machine Shop

Columbia products are USA-made and guaranteed for proper fit, performance, and customer satisfaction. Contact us today at 1-800-547-9471, or visit us at https://www.columbiasteel.com and discover why crusher operations worldwide depend on our 100+ years of manufacturing expertise.

More News

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments

Leonardo A. Fernandez

Need to understand more on manganese alloy and its smelting process