Celebrating Six Decades of Mining Innovation: Thyssen Mining’s Impact in North America

Throughout 60 years of operations, Thyssen Mining has celebrated many milestones and achievements as it grows and continues to expand. Thyssen Mining’s legacy is largely measured by the successful projects completed in close collaboration with its clients and Indigenous partners.

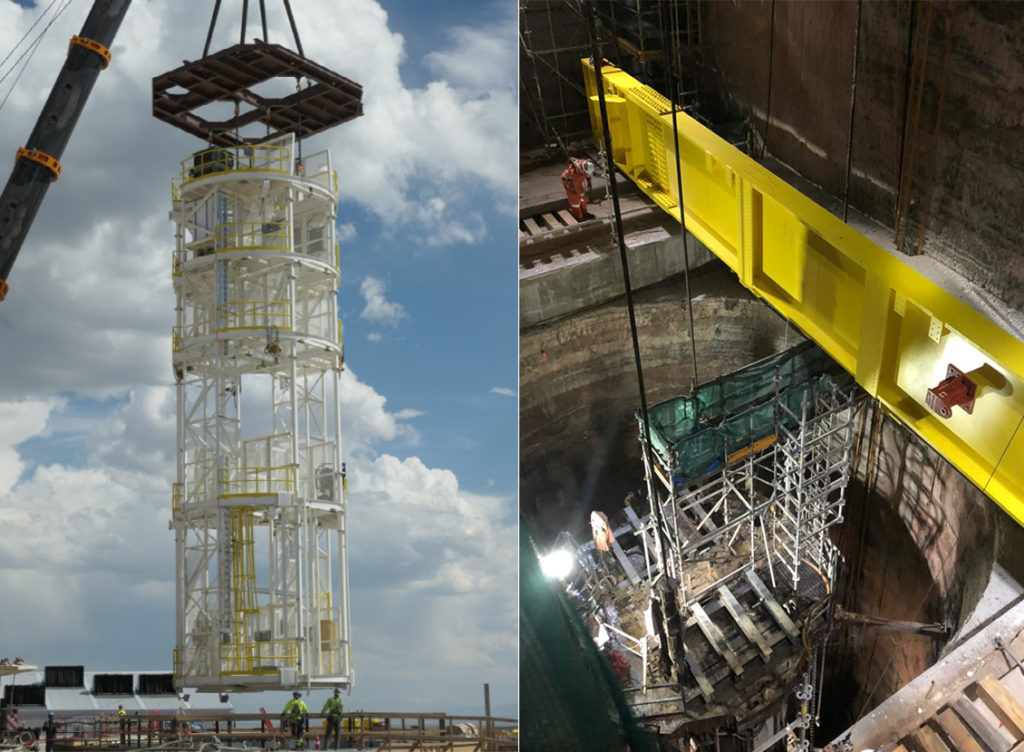

Importing technology in the 1960s from its then Germany parent company, Thyssen Mining’s use of groundbreaking ground-freezing technology and cast-iron shaft liners set a precedent in North America. During the 1960s and early 1970s, it successfully froze the ground for numerous shafts in the Saskatchewan potash mines. Most recently, the technology was used at Mosaic’s K3 Mine.

Thyssen Mining’s history has made lasting contributions to the mining and construction sectors. Its ability to plan and execute complex projects has positioned it as a leading contractor for shaft sinking, mine development, production mining, expansion, and maintenance projects. Thyssen’s fleet of refrigeration equipment supports its expertise in ground freezing, enabling safe excavation in challenging ground conditions and serving various sectors, including traditional mining projects, oil recovery and diamond mining.

Through the years, Thyssen Mining has expanded its services to include electrical, mechanical, civil excavation and construction, ramp development, contract mining, raise boring, and grouting. Thyssen Mining collaborates with clients and project partners to continually pursue what is ‘Best for Project’.

Notable Projects and Innovations in Mining

In Nevada, Thyssen Mining was entrusted with constructing a critical ventilation shaft at the Leeville Turf Mine, marking the state’s first shaft sink using freezing technology. This project highlighted the company’s engineering skills, enabling the completion of the shaft while, demonstrating its commitment to quality and safety.

Thyssen Mining’s people define the company’s culture and they are always looking for the next challenge. Employees like Corrine Joseyounen, a contract administrator, emphasize the opportunities for training and advancement within the company. As an Indigenous woman, Joseyounen values the company’s supportive culture, allowing her career progression and reinforcing her advocacy for others to join the organization. “They’ve always given me opportunity and always willing to train me to allow me to grow.”

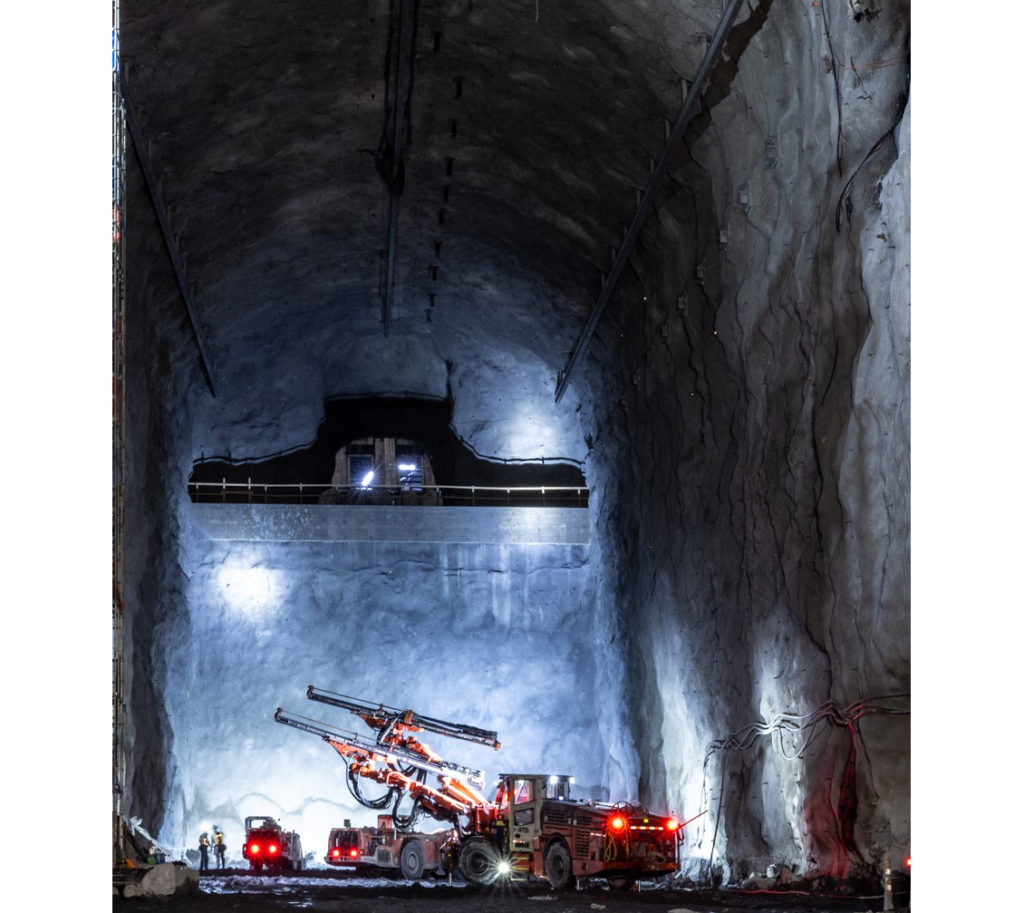

Safety is a core value at Thyssen Mining. Wes Cruea, US Manager of Safety, has been working on a project in South Dakota that is recognized globally, which involves the excavation and construction of three massive underground caverns. “The employees we hire have so much pride in what they do”, said Cruea.

Fostering Collaboration and Safety Culture

Thyssen Mining thrives by integrating its Technical Services, Operations, and Safety teams. This collaborative environment fosters innovation and project-specific solutions while ensuring safety, quality, and outstanding project execution. The Technical Services Group, comprising registered engineers, plays a pivotal role in planning, designing, and innovating to meet project requirements.

The emphasis on safety extends throughout the organization. Employees are empowered to stop work if they feel that safety is compromised, ensuring a secure working environment. Project Manager Kevin Kaspick underscores that safety comes above all else, “Safety is number one and production will come after.” This principle is echoed by senior Safety Coordinator Donovan Cochrane, who advocates for the safety-first approach at all sites, “Safety is always in the forefront right from the top management down to the guys on the floor. It all starts at the top and trickles down”.

Commitment to Community and Workforce Development

Thyssen Mining’s commitment extends beyond projects to community involvement, which is exemplified in northern Saskatchewan. Its joint venture, Mudjatik Thyssen Mining (MTM), employs residents from nearby Indigenous communities, providing valuable skills to the uranium mining industry while at the same time acting as a business partner with those same communities. This initiative not only fosters economic opportunities but also strengthens community ties. Employees benefit from a model emphasizing honesty, integrity, and respect, contributing to their professional and personal growth.

Kaspick’s 38-year tenure with Thyssen Mining, with 27 of those years at MTM, highlights the company’s long-standing impact in the region. MTM is an excellent example of what a strong, collaborative Indigenous business relationship can bring to the mining industry.

Legacy of Success and Future Endeavors

Throughout its history, Thyssen Mining has been instrumental in laying the foundations for Saskatchewan’s resource production, contributing significantly to the province’s uranium and potash sectors. Thyssen’s recent work on decommissioning two potash shaft mines near Esterhazy, Saskatchewan, which it originally helped construct in the 1960s, underlines its ongoing commitment to being a pivotal partner for the underground mining industry. This endeavor earned Thyssen Mining the Exceptional Engineering/Geoscience Project Award from the Association of Professional Engineers and Geoscientists of Saskatchewan (APEGS).

Reflecting on 60 years of operations, Thyssen Mining’s legacy is marked by innovation, safety excellence, and community partnership. The ability to embrace challenges and develop cutting-edge solutions continues to drive growth and development in North America and globally. Through continuous support for its employees and communities, Thyssen Mining forges ahead, building on a history of success to meet future challenges in mine construction and development.

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments