A customized dust control solution for underground mines

Underground hard-rock mines use a wide variety of extraction methods and they have many common dust sources and dust control needs. Ore passes, blasting, drilling, conveying, transferring, crushing, loading, hauling and dump operations can be major sources of dust. For the most part, dust in hard-rock mines is controlled with ventilation air, water sprays, and dust collectors.

Vertical ore and waste passes are created during underground mining operations to transfer material between operational levels using gravity as a motive force. The passes provide a convenient way to handle material between levels and reduce haulage distances. It allows the ore to be loaded into underground bins, sent to an underground crusher or hoisted to the surface from the loading points. Large volumes of fugitive dust are liberated during the dumping process. Dust is not only generated by the physical dumping of material, and subsequent release of fine particles, but also due to the displaced air in the ore pass causing a high velocity rush of air known as the “piston effect”. These fine dust particles are then displaced throughout the mine via the ventilation system where they settle on ledges and into cracks in the walls or on the ground. Due to the small particle size (<10 microns), air movements from the passage of vehicles (loaders, trucks, personnel vehicles, etc) will send them airborne again, creating a safety issue through restricted vision and a health issues through respiration.

Water sprays are used underground but they often present a problem in that they add to the total humidity and increase the bulb temperature of the operation. The human body relies on the evaporation of sweat to cool however, in extreme heat and high humidity, sweat does not evaporate effectively, leading to increased body temperature, heat exhaustion, and potentially fatal heatstroke. High humidity coupled with the high temperature can cause mine personnel to be more easily fatigued.

The water sprays are ineffective because the water evaporates quickly and, in most cases, doesn’t work well at wetting the fine particulate. The ground material can be hydrophobic, or water hating, which doesn’t allow for wetting, leaving puddles of water to evaporate.

Evergreen Solutions has developed a series of chemical binders that provide long term dust control for material handling processes. Our engineered treatment programs are designed for many material handling processes such as conveyors, crushers, and stack outs to storage piles.

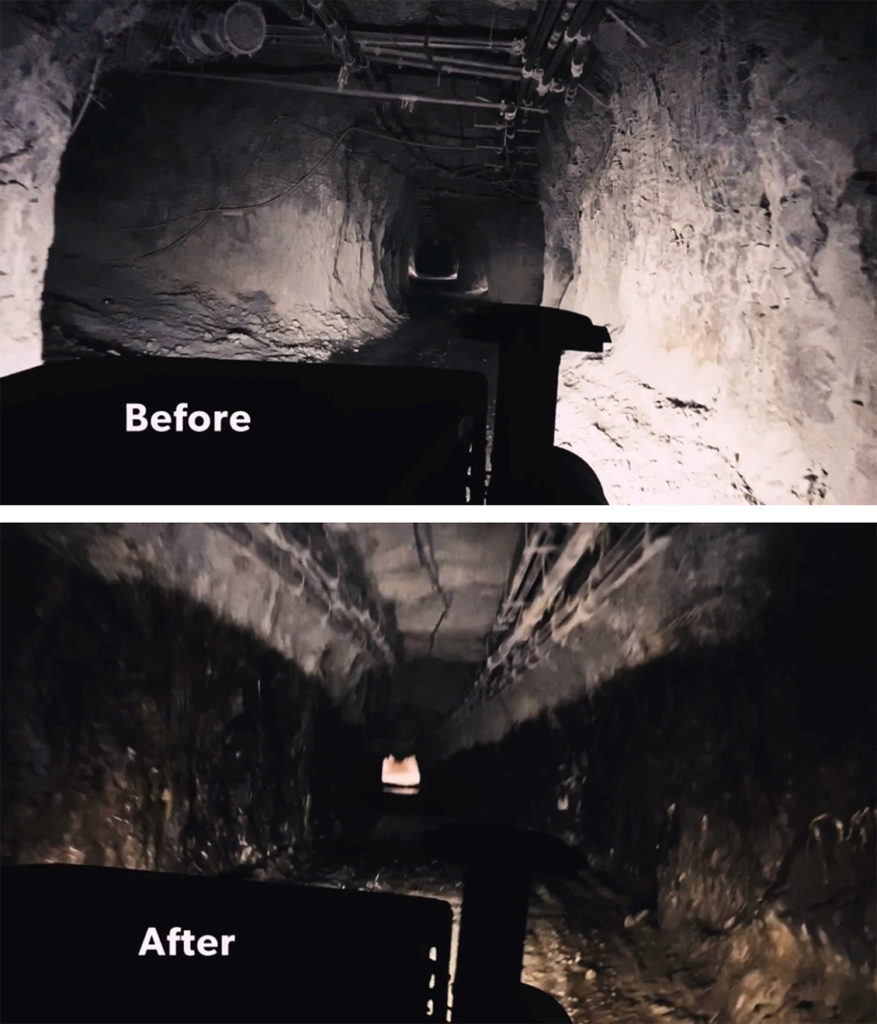

AggreSol binders provide longer term dust suppression versus spraying water in an operation. AggreSol DCC1101 is an organic binder specifically formulated for the underground operations by blending with a food grade preservative to prolong the life of the binder and for mold prevention when using mine service water to dilute the product. AggreSol DCC1101 is very easy to use and apply on walls and haulage areas, by simply diluting in a water truck and spraying on the walls and ramps AggreSol adheres to the surface and binds the particulate to the walls and ramps, not allowing the fine material to become airborne. While the moisture in the binder evaporates, the binder stays active controlling dust.

Because underground operations do not always have an underground water truck and the cost of procuring a water truck can be very high, Evergreen Solutions consulted with the mining industry to develop a cost-effective solution to spraying the AggreSol binder. The AggreSol Skid was borne out of the idea to help mining operations mitigate their dust by providing a complete solution. The skid sprayer is portable and fits on a boom truck or similar vehicle and can be fully dedicated to a vehicle or be lifted on and off to be used when needed.

The AggreSol spraying skid has the following features and benefits. The skid can be fully customized based on the customers need.

- 2000L or 4000L tank – for operational flexibility.

- Underground approved diesel power supply or a hydraulic pump directly connected to the PTO of the truck – for operational flexibility.

- Custom designed spray pattern – for maximum efficiency.

- Ultrasonic level detection – automatic pump shut-off avoids dry pumping.

- In-cab “Tank Empty” indicator light – alerts operator when empty.

- Skid mounted “Tank Full” indicator light – alerts operator to over filling tank.

- Safety beacon – visible to all mining personnel.

- In-cab wired pendant switch control – for ease of use

- Fire extinguisher – for safety

- Stainless steel nozzles and tank construction – for corrosion protection

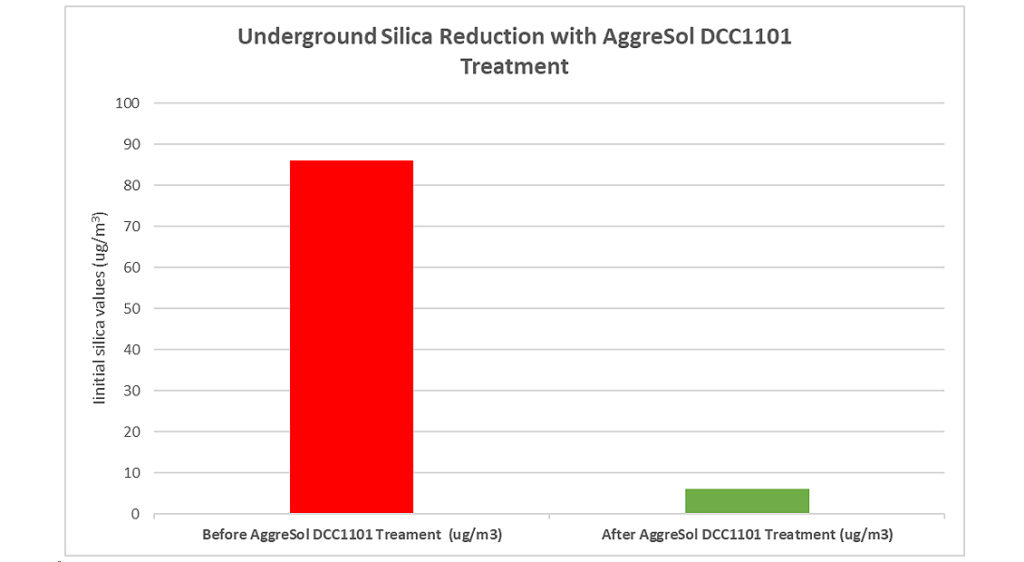

“On June 30, 2023, MSHA proposed a new silica rule for all mines to require use of engineering controls, administrative controls, exposure monitoring, and medical surveillance, and lower the PEL to 50 μg/m3 calculated as an 8-hour time-weighted average per work shift” (CDC – Centers for disease control and prevention).

In one operation, ventilation improvements and the use of AggreSol DCC1101 reduced the silica levels to the following:

The HS&E profile of AggreSol DCC1101 complies fully with Evergreen Solutions’ extremely high standards of user safety and environmental protection. We are proud that AggreSol DCC1101 is a non-regulated, non-flammable, non-combustible and non-corrosive product that outlasts and outperforms hazardous chemicals on the market.

Evergreen Solutions has a long history of providing safe and effective solutions to the mining industry. Our local teams are available for a dust mitigation consultation.

Contact Us Today!

MINING | Evergreen Solutions Corp.

CONTACT | Evergreen Solutions Corp.

Evergreen Solutions Corp.: Overview | LinkedIn

Phone: 403.273.8000 Toll Free: 833.537.6662 Fax: 403.273.8944

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments