Metso has been awarded an order for key concentrator plant equipment by Zijin Mining Group for their Julong copper project in the Tibetan Autonomous region. The value of the order is approximately €85 million, of which 40% was booked in Minerals’ first-quarter 2023 order intake and the rest in Minerals’ second-quarter order intake.

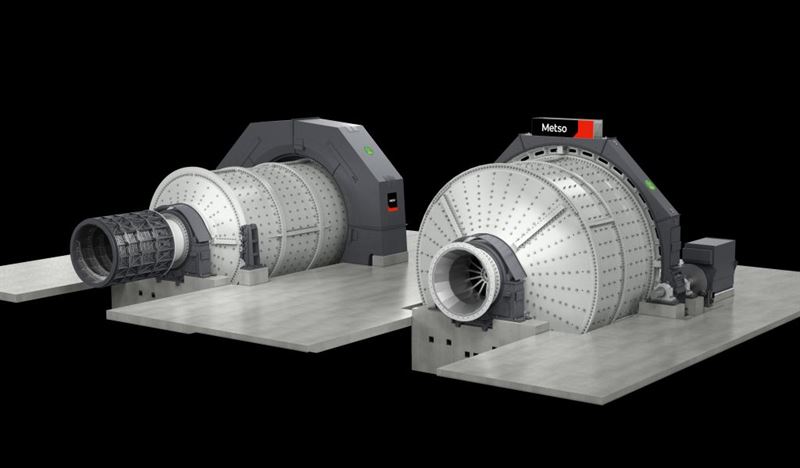

The comminution circuit will be one of the highest powered in China, including a Superior MKIII primary gyratory crusher, a high-power geared Premier SAG mill and gearless mill drive (GMD) Premier ball mill with 24-MW installed power, as well as four Nordberg HP900 cone crushers. To ensure efficient and sustainable concentrate separation, Metso will deliver 24 TankCell TC630 flotation cells, five HRT Hight Rate Thickeners, and two Larox FFP2512 filters. Thanks to their superior energy- and water-efficiency, most of the equipment are part of Metso’s Planet Positive offering.

“We are very pleased to have been chosen as the partner to deliver the concentrator plant equipment for this ambitious project. The Julong Copper mine is located on the Qinghai-Tibetan Plateau at an altitude of 5300m, one of the highest mining sites in the world.”

The elevation of the plant places tough requirements for the equipment. This is one of the reasons Zijin Mining chose Metso, as our technology is known for its sustainability, reliability, and high performance. The delivery includes a gearless mill drive (GMD) ball mill, the first GMD mill to be delivered to China and the most powerful ball mill ever made.”

TankCells and High Rate Thickeners to be delivered are high-capacity equipment, reducing embedded carbon and increasing overall plant availability. Two of the thickeners are for tailings and are 100 meters in diameter. In addition, our local service capability is highly appreciated by the customer,” says Xun Fang, Head of Metso’s Minerals Sales in Greater China.

Comments