Sumitomo Metal develops rechargeable battery recycling technology

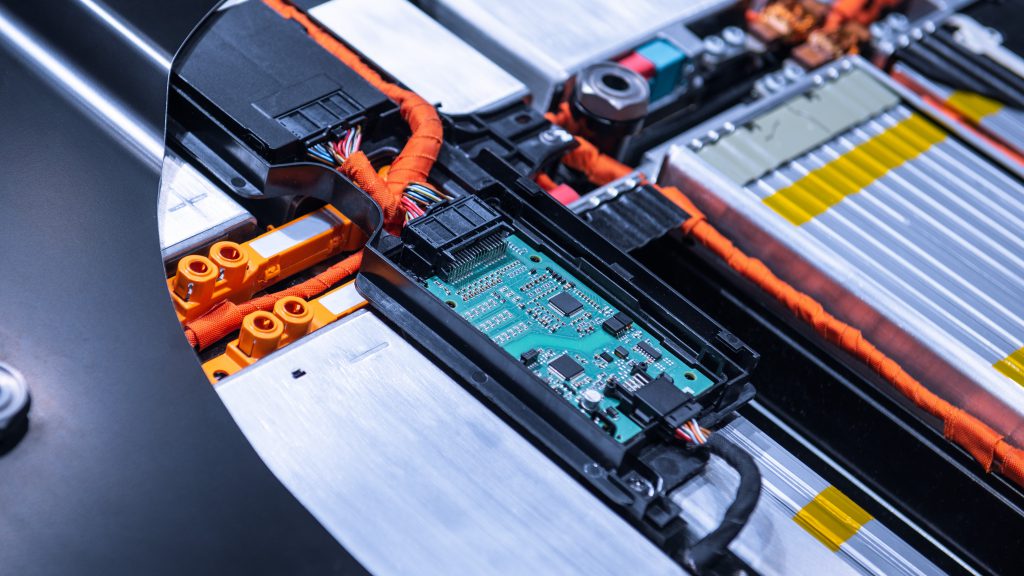

Japan’s Sumitomo Metal Mining Co Ltd said on Monday it had developed a technology to recover nickel and cobalt from rechargeable batteries such as used lithium-ion-batteries (LIBs) that can be reused as raw materials for LIBs.

Japan’s biggest nickel smelter, which has been able to recover nickel and copper from rechargeable batteries since 2017, has successfully recovered a high-purity nickel-cobalt mix by separating impurities, it said in a statement.

After manufacturing and evaluating LIB cathode material from the recycled nickel-cobalt mixture, experiments have shown the performance of the batteries was equivalent to those made using raw materials derived from natural resources.

“No commercialisation plans have been set yet, but we will continue to work on the development toward making it commercially viable,” a company spokesperson said.

Sumitomo Metal supplies nickel-based cathode materials for Panasonic Corp’s LIBs that are used in Tesla Inc electric vehicles (EVs).

The smelter has also produced a soluble slag that enables lithium recovery by a smelting process in demonstration, it said, helping to establish a new recycling process for copper, nickel, cobalt and lithium from used rechargeable batteries.

As the world moves to meet stringent targets for cutting carbon emissions – partly by phasing out internal-combustion-engine cars – demand for lithium, cobalt and nickel vital for electric vehicle batteries is set to soar, raising the prospect of shortages.

Securing stable supplies is a major challenge as production regions for these rare metals are unevenly distributed, which makes demand for recycling greater.

“If we can commercialize this ‘battery to battery’ recycling process, we can contribute to a formation of sustainable circular economy and response to global resource depletion,” Sumitomo Metal said.

(By Yuka Obayashi; Editing by David Evans)

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments