The key to confidence in the diamond sector

They say that confidence is the key to success, and that preparation is the key to confidence.

And from my years as President of De Beers Group’s International Institute of Diamond Grading & Research (IIDGR), I can safely say that this is certainly true of the diamond sector.

Confidence is an increasingly vital component of success at all stages of the diamond value chain, and you can’t provide that confidence unless you have a wealth of knowledge and hard work behind you.

That’s why De Beers Group established IIDGR, and why we’ve seen such exciting growth since launch – it’s all about confidence.

Ever since De Beers was established in 1888, we’ve been building an immense knowledge-base about diamonds and all aspects of the diamond sector.

We’ve been at the forefront of all the key developments in the industry and have acquired the experience and expertise that sets us apart as the authority on all things diamond-related.

But what many people outside of De Beers Group may not realise is just how much work goes into ensuring we stay at the leading edge of diamond developments.

We invest huge amounts of money, time and effort to ensure that we remain ahead of the game. We’ve been one of the leading researchers into diamond synthesis since the 1950s.

Since then, we’ve invested more than any other business into R&D on synthetics and detection capability – and in the last two years alone we’ve invested more than US$25 million in establishing a world-leading facility in Surat in India, to accompany our other IIDGR facilities in Antwerp and Maidenhead.

And beyond this, the structure of our business across the value chain means we are perfectly positioned to make the whole greater than the sum of the parts.

For example, with different parts of our business employing some of the world’s leading experts on diamond synthesis, we have the ideal opportunity to pressure test our own synthetic diamond detection capabilities.

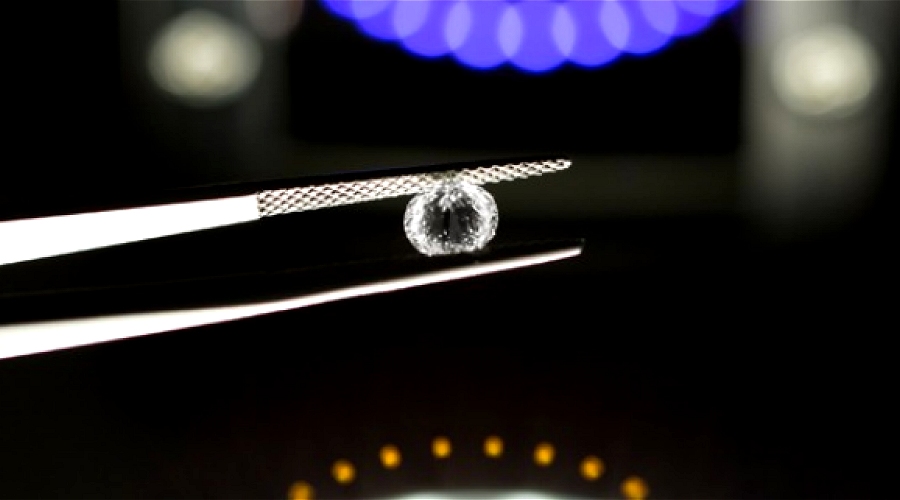

In effect, we play an internal game of ‘cops and robbers’, where we challenge our colleagues in Element Six to develop new and ever more challenging types of synthetic diamond material so that our colleagues in De Beers Technologies can find the best ways of detecting them – and we certainly have the right skills in place to provide us with the toughest challenge possible.

Recognised among the top 10 companies globally for patent grants in any field of endeavor by the U.K. Intellectual Property Office, Element Six now holds more than 450 granted patents across 73 patent families relating to single crystal diamond technology in more than 20 countries around the world.

Once we have been set the challenge with the latest synthetic diamond developments, we then build our detection instruments and services around these challenges so we can ensure all types of synthetic diamonds remain readily detectable.

We set the bar very high for our technology and expect that each instrument we release should be tested to the highest possible standards, while also being fast, efficient and affordable.

By starting our development with the toughest challenges in mind, then seeking ways to make that high performance suitable for a cost-effective and practical solution, we ensure that each device we sell is an excellent fit for industry needs.

And having a steady stream of industry-leading synthesis research on which we can continue testing our instruments means that we can always remain at the cutting edge.

The importance of this pressure-testing approach is made particularly clear when looking at cases such as that recently reported in the trade press under the headline, “GIA finds baffling flaw in CVD diamond”.

This news article suggested that a particular feature, that is usually only found in natural diamonds (known as ‘H4’), had been discovered in a CVD synthetic stone. While the article noted that this had left scientists at the lab to which the stone had been submitted “scratching their heads”, our own approach means we had previously recognised the potential for this to happen.

Our scientists already knew that, by applying a specific set of treatment conditions to certain categories of CVD synthetic diamonds, it is possible to generate the impurity responsible for the H4 feature, albeit in very low concentrations.

As a result of our knowledge and experience, the presence of the H4 feature would not have led to any ‘head-scratching’ if it had arrived at our labs, and would not have presented any problems at all for our detection technology, including the recently-launched AMS2 and SYNTHdetect.

The CVD synthetic stone highlighted in the article is certainly unusual in that it lay in the overlap region between natural and synthetic diamonds for one specific feature, but it does not represent a fundamental change in the way we go about detecting such stones.

And neither does it present a challenge to the instruments that are leading the way in providing reliable identification of synthetic diamond material, because we develop them with circumstances just like this in mind.

So it’s good to know that even when these new and strange situations occur as synthetic production techniques develop, those using our technology or services can remain confident.

This is because more than 125 years of De Beers Group experience and preparation, and millions of dollars of investment, are delivering the assurance that every diamond business requires.

Written by Jonathan Kendall. President, International Institute of Diamond Grading & Research. Published first at De Beers blog.

More News

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments