Daimler’s R&D chief sees nickel rich batteries gaining traction

GENEVA, March 6 (Reuters) – The car industry is moving towards making electric car batteries with a higher ratio of nickel, Ola Kaellenius, Daimler board member responsible for research and development, said on Tuesday.

High cobalt prices have been pushing manufacturers to adjust the recipe for the batteries used to power electric cars to reduce the amount of cobalt and increase the nickel content.

Each electric car battery uses between 8-12 kilograms of cobalt. More than half of annual mined supply of cobalt is sourced from Democratic Republic of Congo.

Kaellenius said carmakers had also tried to increase the operating range of electric cars by experimenting with the ratio and mix of nickel cobalt and manganese in batteries.

“The main trend is toward NMC,” Kaellenius said, referring to nickel manganese and cobalt. “We saw a mix of 1:1:1 then we went to 6:2:2 and now some suppliers are even talking about 9:05:05,” Kaellenius said of the ratio of materials.

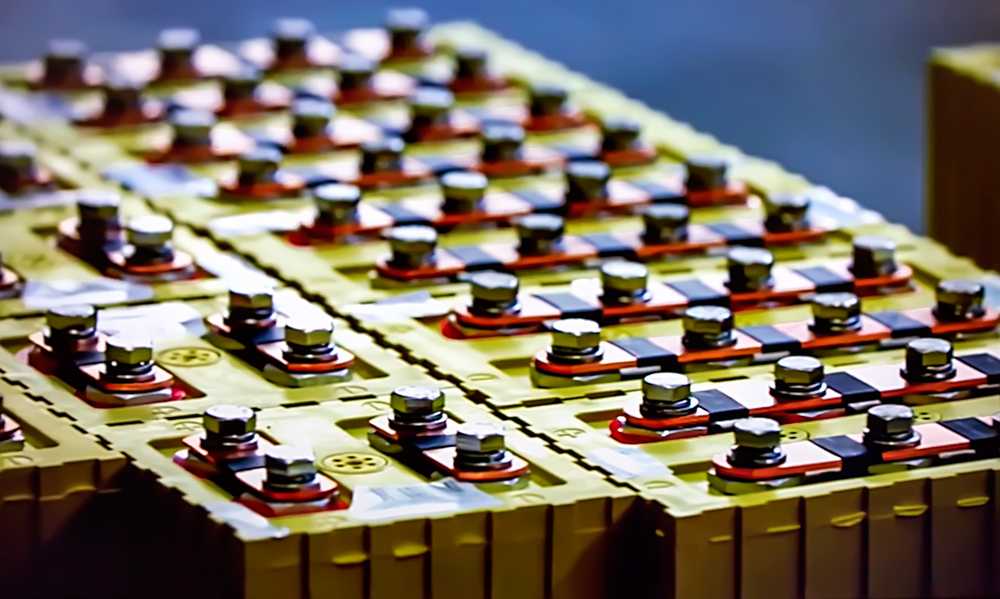

The auto industry currently has a range of different battery recipes competing for use in battery cathodes.

One is NCA, or lithium nickel cobalt aluminium oxide, produced by Panasonic and used by Tesla which competes with NMC, lithium nickel manganese cobalt oxide.

Chinese manufacturers use a composition called LFP which has a lower energy density but also does without cobalt, while Japanese carmakers use LMO, or lithium manganese oxide, which is used by Nissan and LG Chem.

(Reporting by Edward Taylor; Editing by Jane Merriman)

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments