UBC scientists take ideas from the lab bench to the mine site

If you have a mine company with a tailings pond full of coal slurry or a coal deposit that is no longer economic, there could still be value in it. It may contain enough rare earth elements to make it worth processing.

And if you have a nickel, diamond or platinum mine, you might be able to turn your mine waste into a carbon capture and sequestration project. And through some clever chemistry, you might also be able to put molecules to work to concentrate gold or other precious minerals in your tailings ponds to make it worth recovering.

These are just some of the areas of mining-related research being pursued by scientists in B.C., through organizations like the Norman B. Keevil Institute of Mining Engineering at the University of British Columbia (UBC) and Geoscience BC as well as through UBC’s Bradshaw Research Initiative for Minerals and Mining.

The Norman B. Keevil Institute focuses on taking ideas from the lab bench to the mine site. Among the innovations to come out of the institute that are now being used commercially are the sensors used by MineSense to pre-sort ore before it goes to processing mills.

Earlier this year, with funding from Geoscience BC, researchers with the Keevil Institute began studying coal seams in the East Kootnays. But they weren’t looking for coal.

“The past research has shown that coal seams may be a source of rare-earth elements,” said Christa Pellett, Geoscience BC’s vice-president of minerals. While there is a growing demand for rare-earth elements for rechargeable batteries, renewable energy and electronics, the question for researchers will be whether they are sufficiently abundant in coal deposits or tailings ponds to be economically recoverable.

One area of next-generation research that is still wide open is using microbes for concentrating, eliminating or sequestering minerals or toxic compounds

Mining and B.C.’s other traditional resource industries have provided the province’s clean-technology industry with plenty of problems to solve. There is a lot of synergy between the two sectors.

“Vancouver, I think, in particular, has a golden opportunity for it to become a major centre for innovation in mineral resources,” said Scott Dunbar, department head of the Norman B. Keevil Institute. Because mining is so interdisciplinary, the institute works with a number of other science and engineering departments at UBC as well as with other research groups.

Dunbar’s research is in the use of macromolecules that will bind to minerals of economic interest. “We have ones that bind particularly to chalcopyrites and gold,” Dunbar said. “We think it might be useful in trying to get at very fine particles that are missed in flotation before they go out to tailings and get lost.”

On the energy side, researchers are working on ways to capture and use heat from diesel generators at mine sites. Those generators also produce carbon dioxide, and one of the more promising research areas is capturing CO2 from those generators and sequestering it in tailings.

Some elements and minerals in the host rock of certain types of mines will naturally react with CO2. The host rocks for nickel, cobalt, platinum and diamonds typically contain elements that naturally react with CO2 to form carbonates.

The idea is to augment this natural process by capturing CO2 from generator exhaust, cooling it and then piping it beneath mine tailings. As the CO2 percolates up through the tailings, some of it becomes sequestered as magnesium carbonate.

Gregory Dipple, a professor at UBC’s department of earth, ocean and atmospheric sciences, has been leading the research, in partnership with the Keevil Institute. Earlier this year, thanks to $2 million in funding from Natural Resources Canada, Dipple’s research team conducted its first field trial at a Northwest Territories diamond mine.

At full scale, Dipple estimates, anywhere from 20% to 100% of the CO2 could be sequestered, but a lot depends on the host rock and composition of the tailings. Like most carbon capture and sequestration, carbon pricing would need to be at about $60 per tonne to make the economics work.

Dunbar said one area of next-generation research that is still wide open is using microbes for concentrating, eliminating or sequestering minerals or toxic compounds.

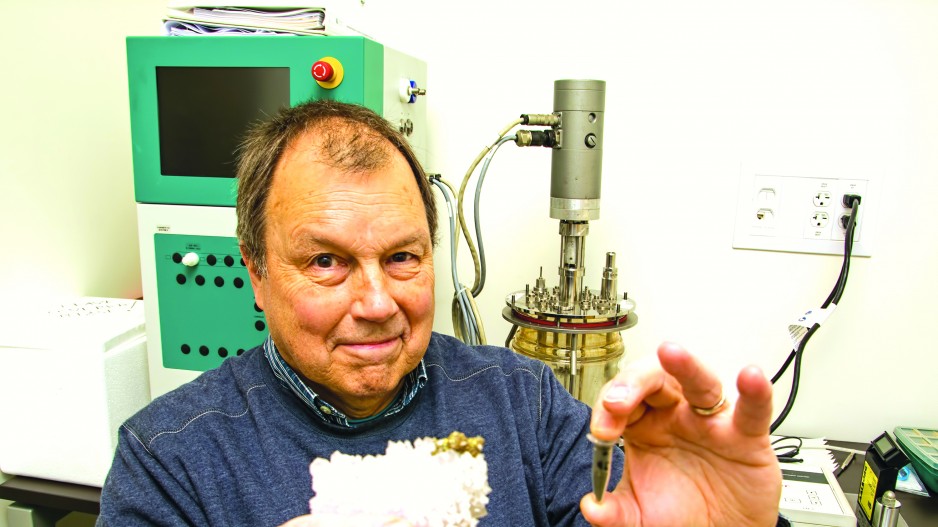

Susan Baldwin, a UBC chemical and biological engineering professor, has been working with Genome BC and Teck Resources (TSX:TECK.B), which has provided funding, for research aimed at using microbes to remove toxins from tailings.

The selenium released from coal mining can be toxic to fish. Baldwin’s research is focused on using nutrients to boost microbes that naturally absorb the selenium.

“The thing that’s not been tapped into very well is biotechnology,” Dunbar said. “Microbes have been interacting with minerals for about two billion years, and there’s just a whole bunch of genetic information there that we are just beginning to tap into.”

(This article first appeared in Business in Vancouver)

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments