New Metso Outotec: Focus on Innovations Supporting Sustainable Development of the Industry

The long anticipated Metso and Outotec merger completed June 30, and the newly combined company, Metso Outotec, a leader in sustainable aggregates, minerals and metals processing and recycling technologies, officially began operations July 1.

The merger combined the footprints of two industry powerhouses – with Metso providing machinery critical to the industry with a strong service focus, and Outotec a cutting-edge technology driven organization. Helping customers improve their profitability and lower their operating costs and risks with solutions and services supporting sustainable development of the industry are key targets for Metso Outotec.

The new company is a holistic entity with over 15,000 professionals in more than 50 countries, and its illustrative combined sales for 2019 were about €4.2 billion in 2019.

Pekka Vauramo, president and CEO, Metso Outotec said the merger was complex, with lots of moving parts, but success was achieved moving through the journey.

Vauramo said the new company would be able to create €100 million in core synergies and €150 million in revenue synergies.

According to Vauramo, Metso Outotec is a key partner for positive change for tomorrow’s aggregates, minerals, metals and recycling industries.

“Metso Outotec is now wholly focused on mining, metals and aggregates. Earlier, Metso had two businesses – minerals and flow control. We spinned off the flow control and merged, bringing in a group focused on mining and metals,” Vauramo said.

“[It] brings in synergies in serving customers on the product side, and Metso and Outotec complement each other with their minerals and services offering. We have a high degree of complementarities.”

€100 million spent on research and development per year

Metso Outotec is spending about €100 million on research and development (R&D), per year. The company is particularly focused on the challenges the mining industry faces with lower ore grades making critical metals tougher to extract.

““€100 million is more than any of the other companies in this field is spending on R&D, and we are ready to spend even more – it’s important to develop the processes. And with the best talent in the industry, we can expect new innovations to take our industry forward.”

“If we can separate the valuable from the non-valuable parts early on, it means there is less energy needed to process the material and filtrating the water. We want to get into the roots of the energy consumption as well as and making really efficient water circulation. That’s where Metso Outotec can and will contribute.”

“The amount of metals that are needed in electrification – battery metals, like copper and nickel – is constantly increasing and they need to be produced out of lower-grade ores. This means that more and more materials need to be handled,” Vauramo said, adding the company’s goal is to develop solid processes to sustainably extract the metals.

“Almost all metals are becoming important to electrification, which is key in enabling modern life. We need to make the world understand that the metals don’t come from nothing – they come from the mines. They also need to be efficiently recycled, and that is where our industry is developing. New, fresh metals are needed, too. The industry needs to improve, and we want to be part of it in a sustainable way.”

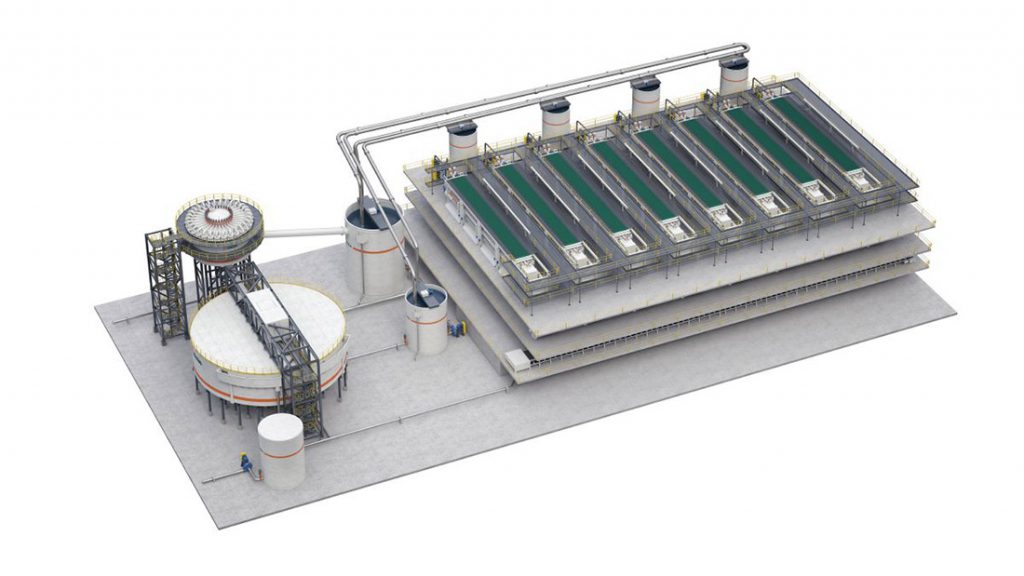

“Efficient technologies to re-circulate water are key, because water management is becoming one of the most important issues. On the tailings management side, dry stacking of tailings is becoming more and more important also because of the dam failures that have happened.”

Salares Norte gold mine in Chile, for example, has acquired Metso equipment for drystacking of tailings.

“We work with our customers to spend money wisely, and in the areas where the need is biggest…and what is required in the industry. [Some] copper grades that are now being mined are below 1%, and that means that 99% of what mines are producing is tailings. Handling huge volumes of tailings is costly and if it’s stored in dams, it can become, over time, dangerous,” Vauramo said.

New innovations to support sustainable development

Vauramo said the new Metso Outotec Corporation will remain focused on service as well as on innovating new equipment that will is needed to support the sustainable development of the industry, year after year.

“With climate change, it’s more and more important to get the water usage under control, and in a wider space it is important to take care of people – taking care of our own people, taking care of our customers, and taking care of the communities we visit,” Vauramo said.

Discover more at https://www.mogroup.com/?utm_source=mining-com&utm_medium=article&utm_campaign=day1&utm_content=mogroup-intro

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments