Metso Outotec Geminex™ enables a digital leap for better environmental and financial performance

The mining industry is continuously challenged by megatrends such as declining ore grades, resource and knowledge scarcity, environmental conditions, and wider topics such as sustainability and digitalization.

To answer these challenges, Metso Outotec has outlined sustainability as a strategic priority and decided to place it at the core of its offering and operations. As a result of this, Metso Outotec developed Planet Positive – their approach to sustainability. The products and services in their Planet Positive portfolio address customers’ sustainability needs by being demonstrably more energy or water efficient than the industry benchmark.

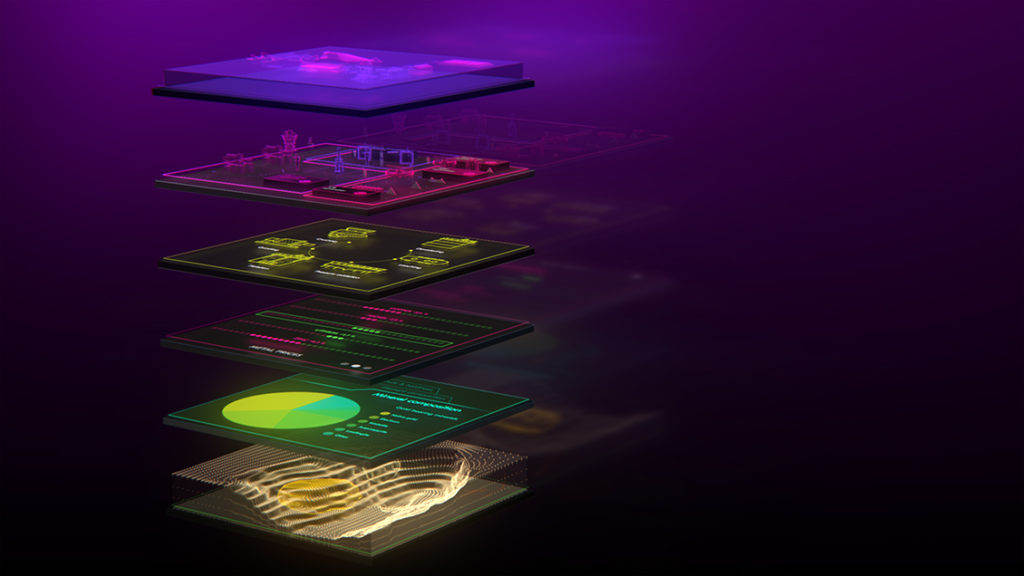

One major addition to Metso Outotec’s Planet Positive portfolio and digitalization offering is the Metso Outotec Geminex™. Geminex is a metallurgical digital twin that combines operational data and expertise to deliver insight-driven performance that boosts efficiency and sustainability onsite. The solution is a combination of a physical plant simulation model and AI with an online connection, used for online monitoring of processes and operator training in a realistic virtual environment.

The Geminex™ concept has been in development for years, and Metso Outotec has been building on their simulation technologies. Now the offering has been fully packaged into Metso Outotec Geminex™, and the digital twin solution is already in use at several mine sites.

We sat with Jari Moilanen, Director of Digital Solutions, Metso Outotec, to learn more about this digital leap.

How does the solution improve resource efficiencies and help reduce emission footprints?

By using the right amount of energy to get the best of the orebody. Using too much or too little energy could lose valuable minerals into the tailings. Too little, you could lose on the economics of the operation. Scenarios find optimal “recipes” to process different types of ore, [whether] the ore is high or low grade, or there are changes in the operating assets due to planned or unplanned shutdowns,” [RL1] Resource efficiency is improved when one can predict the best alternatives and what needs to be done if there are changes in the feed, or operating assets.

What is the importance of digital twins in today’s context? What is changing and why do we need solutions like these in future?

The industry is aiming to become more sustainable, and many companies are implementing a sustainability strategy, without wanting to compromise any operational targets.

“This solution improves the sustainability of operations and eventually, will decarbonize operations.”

All processes and operations from the mine to the mill and to the smelting plant, have a need for enhanced optimization. It is the full value chain optimization that requires the power that Metso Outotec Geminex™ simulations and Artificial Intelligence (AI) is capable of unlocking.

How has Metso Outotec gone beyond research & development to become pioneers in digital twins?

Metso Outotec has been actively developing static and dynamic modelling with HSC Sim around the world for more than two decades, selling over 20,000 licenses. In this sense we could say that Metso Outotec is a pioneer and in the forefront of metallurgical digital twin development, which can be proven by positive customer experience and results.

“Geminex is a customer-driven development. We have worked with our customers to identify the challenges they face, and even worked with them in building the tool itself to make sure it was applicable to the industry.”

Are there some immediate gains? What does the short-term impact look like, and what can digital twinning potentially change in the long term?

The industry has accepted digital twin technologies into the market and the demand is constantly growing. The immediate gains are related to operators’ highly improved situational awareness and better understanding of the processes. Digital twins allow operators to make informed decisions and select the best outcome. Depending on the operation and starting point, the results can be game changing.

In the long term, the technology will make operations more sustainable in terms of water usage, and profitability.

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

2 Comments

Michael Segaiso

Interesting…I hope the product will be beneficial in our diamond mining industry

Walter Puffelis

PLEASE GIVE A CALL FOR A QUOTATION FOR A MINE DEVELOPMENT