Get more than just wear parts — get performance solutions made in USA.

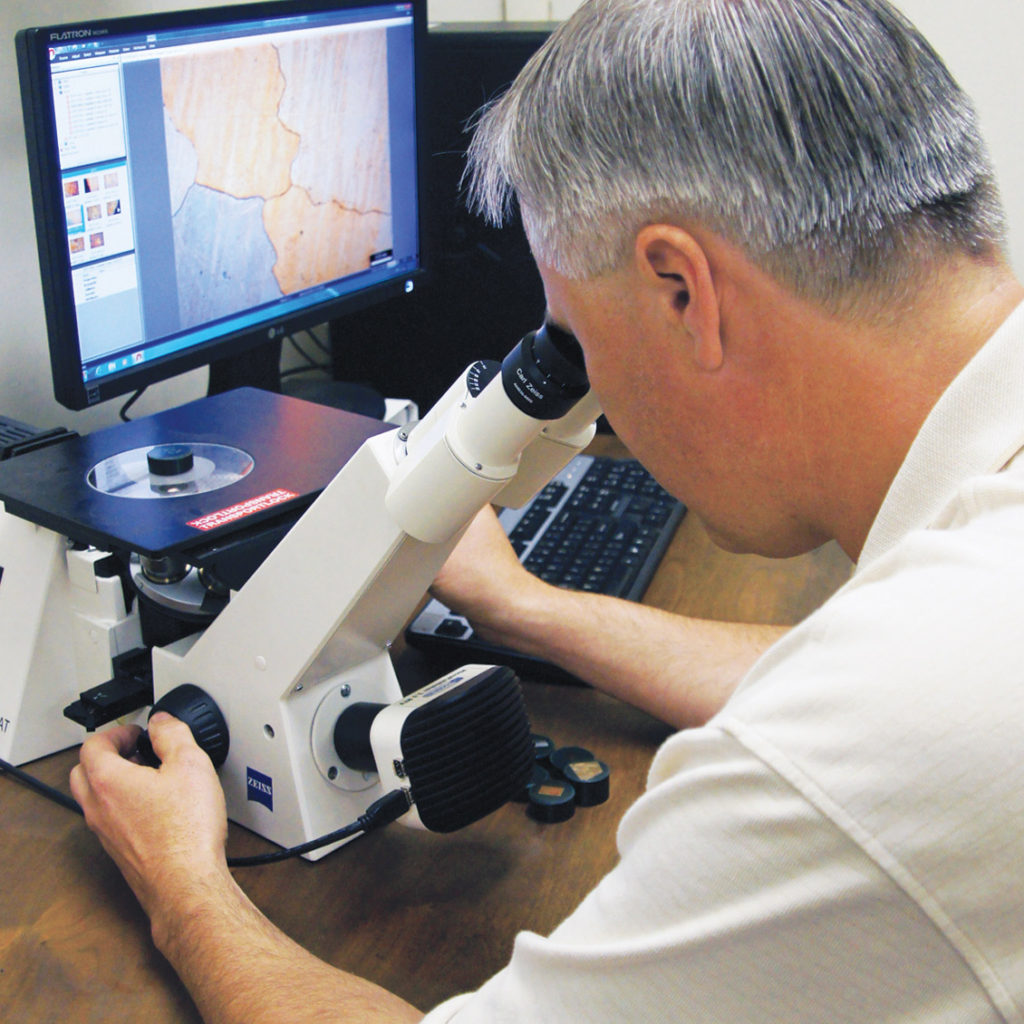

When you’re ready to improve your crusher performance, get the facts first. Crusher wear analysis by Columbia Steel takes the guesswork out of wear part choices, benefiting your operation with better production and less downtime. Our district managers and engineers begin by collecting real-world data on your equipment: feed and discharge information, throughput rates, change out records, and measurements on worn parts. You’ll then receive recommendations for parts best suited to your specific situation.

There’s a Columbia Steel alloy designed to meet every level of impact and abrasion encountered in your operation.

For example, our Xtralloy® 24% manganese steel provides longer life in many cone and jaw crusher applications. Alloys of appropriate hardness and toughness are available for each level of your gyratory crushing chamber to greatly reduce maintenance costs. Our H79 alloy steel hammers provide reliable, consistent service for secondary and primary crushers. Columbia Steel can also supply manganese hammers with our Xtend Process® chrome carbide overlay.

We have thousands of crusher replacement wear part patterns available, and are always at your service to create custom and OEM-style solutions as well.

We offer the broadest range of crusher wear part styles and designs of any single manufacturer in the industry, for gyratory, cone, jaw, roll, hammermill, and impact crushers. Columbia Steel’s product engineers are experts in designing wear part profiles to increase overall wear life, and to improve production throughout the life of the part. Got a crushing challenge? We improve wear parts to handle oversize material, break up slabby material, and reduce recirculation for better overall plant performance. Need a custom design? Our engineers and on-site pattern shop are here to help.

About Columbia Steel

Our customers know there’s more to a Columbia Steel casting than just metal. Founded in 1901, our full service manufacturing facility puts our engineering and metallurgy know-how directly at your service, including:

- Casting Simulation Lab

- 126,800 Sq. Ft. Foundry

- On-site Pattern Shop

- 71,000 Sq. Ft. Machine Shop

All Columbia products are USA-made and guaranteed for proper fit, performance, and customer satisfaction.

Contact us today at 1-800-547-9471, or visit us at www.columbiasteel.com and discover why crusher operations worldwide depend on our 100+ years of manufacturing expertise.

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments