Silver becomes key component for ultra-efficient solar cells

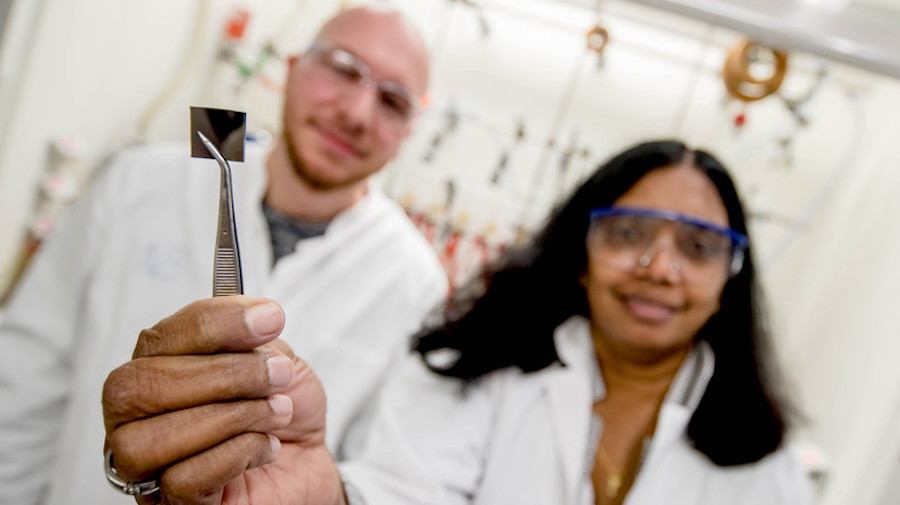

Researchers at Ruhr-Universität Bochum and the University of Wuppertal in Germany have come up with a new fabrication process for transparent ultra-thin silver films. The new process produces a material capable of increasing the efficiency of solar cells and light-emitting diodes.

Up till now, traditional chemical methods have not been able to produce ultra-thin and pure silver films, the scientists say in a research paper published in the journal Angewandte Chemie.

This is because precursors for the fabrication of ultra-thin silver films are highly sensitive to air and light. They can be stabilised with fluorine, phosphorus or oxygen but these elements contaminate the thin films as well as the equipment used for the production.

However, with the newly developed synthesis, the team headed by Professor Anjana Devi and Nils Boysen were able to create a chemical silver precursor where the silver is surrounded by an amide and a carbene, which is even stable without fluorine, phosphorous or oxygen.

Following this process, they demonstrated that a silver thin film can be applied to an electrode with the new precursor by atomic layer deposition. When this is done, the gaseous precursor is transported to the electrode and a silver film is deposited there as a layer with a thickness of merely a few atoms.

Because it is so thin, the silver film is transparent. It is also pure and electrically conductive. “As far as process technology is concerned, the successful synthesis of the new precursor paves the way for the development of ultra-thin silver films,” said Thomas Riedl, from the Chair of Electronic Devices in Wuppertal, in a media statement. “It constitutes a first step towards the production of novel electrodes for highly efficient solar cells and lights.”

In the same brief, team lead Anjana Devi added that since the process can be operated under atmospheric pressure and at low temperatures, the conditions for industrial production are favourable.

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments

Andrés Sorribes Fernandez

Good ??