EDM Announces Successful Results of Dense Media Separation Study on High-Grade Ores of the Scotia Mine

Halifax, Nova Scotia--(Newsfile Corp. - January 6, 2025) - EDM Resources Inc. (TSXV: EDM) (FSE: P3Z) ("EDM" or the "Company") is pleased to announce the initial Heavy Liquid Separation ("HLS") test results on high-grade zinc and lead composite samples from its Scotia Mine. The initial tests indicate that it may be possible to pre-concentrate crushed run-of-mine high-grade material using Dense Media Separation ("DMS") prior to flotation, thereby potentially reducing the overall cost of mineral processing at the Scotia Mine.

The results of the initial HLS tests at 3.00 SG on the high-grade samples resulted in:

Test T1 (12.7mm crushed size): increase in grades by 35% for Zinc and 26% for Lead while retaining 97.3% of the Zinc and 99.4% of the Lead

Test T2 (6.3mm crushed size): increase in grade by 28% for Zinc and 13% for Lead while retaining 97.6% of the Zinc and 99.4% of the Lead

"EDM is very encouraged by the results of the high-grade HLS test work, which indicated almost full recoveries of both zinc and lead mineralization using the HLS bench-scale analyses, with a strong separation of the non-mineralized material from the total processing feed," said Mr. Mark Haywood, President & CEO. "In addition, DMS test work continues on the blended mineralized materials as part of our ongoing optimization of the Scotia Mine," he added.

DMS Processing and HLS Testwork Details

A Dense Media Separation plant utilizes a gravity separation process that relies on the differences in density between mineralized rock and non-mineralized rock, and used a non-toxic slurry of heavy media and water to effect a separation. HLS testing is a bench-scale process that is used to simulate the full-scale DMS process. It utilizes a bath of organic heavy liquid at various densities to incrementally split out the heavier mineralization (which sinks in the liquid) and the lighter waste (which floats to the top of the liquid).

On an industrial scale, a DMS plant at the Scotia Mine would be designed to pre-process a crushed run of mine stream, and to significantly reduce the amount of sub-economic (waste) material that would otherwise be processed through the Scotia Mine's mill. As a relatively simple, environmentally friendly and cost-efficient metallurgical process, a DMS plant can significantly reduce the overall processing costs at the Scotia Mine which would also allow a lowering of cut off grade and access to otherwise uneconomic areas of the deposit.

The HLS tests were performed on material from two 10-kilogram samples that were collected from the high-grade mineralized zones of the Scotia Mine. One sample was 100% crushed to 12.7mm (1/2") in preparation for "Test T1". On completion of Test T1, the sample was then crushed to 6.3mm (1/4") for "Test T2". The minus 0.85mm size fraction was removed prior to HLS testing. The head grades of the high-grade sample are shown as follows in Table 1, with the results of Test T1 and Test T2 shown in Tables 2 and 3 below:

Table 1 - Sample Head Grades

| Zn% | Pb% | |

| High-Grade | 18.4 | 36.8 |

Table 2: Test T1 Results

| Product | Weight | Assays (%) | Distribution (%) | ||

| (%) | Zn | Pb | Zn | Pb | |

| HLS 3.20 SG Sink | 73.2 | 25.6 | 48.4 | 96.3 | 99.1 |

| HLS 3.10 SG Sink | 74.1 | 25.4 | 47.8 | 96.8 | 99.2 |

| HLS 3.00 SG Sink | 76.5 | 24.8 | 46.4 | 97.3 | 99.4 |

| HLS 2.90 SG Sink | 77.5 | 24.5 | 45.9 | 97.8 | 99.5 |

| HLS 2.85 SG Sink | 78.9 | 24.2 | 45.1 | 98.2 | 99.6 |

| HLS 2.80 SG Sink | 81.9 | 23.4 | 43.5 | 98.6 | 99.7 |

| HLS 2.75 SG Sink | 83.7 | 23.0 | 42.6 | 98.9 | 99.7 |

| HLS 2.75 SG Float | 16.3 | 1.3 | 0.6 | 1.1 | 0.3 |

| Head (Calc.) | 100.0 | 19.5 | 35.7 | 100.0 | 100.0 |

Table 3: Test T2 Results

| Product | Weight | Assays (%) | Distribution (%) | ||

| (%) | Zn | Pb | Zn | Pb | |

| HLS 3.20 SG Sink | 74.1 | 25.0 | 44.6 | 95.6 | 98.8 |

| HLS 3.10 SG Sink | 76.1 | 24.6 | 43.5 | 96.8 | 99.1 |

| HLS 3.00 SG Sink | 80.2 | 23.6 | 41.4 | 97.6 | 99.4 |

| HLS 2.90 SG Sink | 81.2 | 23.4 | 41.1 | 98.2 | 99.6 |

| HLS 2.85 SG Sink | 82.9 | 23.1 | 40.2 | 98.7 | 99.7 |

| HLS 2.80 SG Sink | 85.4 | 22.5 | 39.1 | 99.0 | 99.8 |

| HLS 2.75 SG Sink | 93.6 | 20.7 | 35.7 | 99.7 | 99.9 |

| HLS 2.75 SG Float | 6.4 | 0.9 | 0.4 | 0.3 | 0.1 |

| Head (Calc.) | 100.0 | 19.4 | 33.5 | 100.0 | 100.0 |

The following two charts show these results on a cumulative basis (excluding fines) and highlight how the incremental recovery of mass and metal drops slightly towards the higher HLS "cut point" densities.

The recoveries shown in these figures do not include fines. Figure 1 illustrates the results of Test T1, and Figure 2 illustrates the results of Test T2.

SGS selected an optimal SG of 3.00 for recoveries of zinc and lead, as well as the mass recovered.

For Test T1: At an optimal SG of 3.00, 76.5% of mass is retained, along with 97.3% of zinc and 99.4% of lead

For Test T2: At an optimal SG of 3.00, 80.2% of mass is retained, along with 97.6% of zinc and 99.4% of lead

Figure 1: Test T1 Results (Recovery vs Density)

To view an enhanced version of this graphic, please visit:https://images.newsfilecorp.com/files/6904/236109_2154dcb1a4dd2b44_002full.jpg

Figure 2: Test T2 Results (Recovery vs Density)

To view an enhanced version of this graphic, please visit:https://images.newsfilecorp.com/files/6904/236109_2154dcb1a4dd2b44_003full.jpg

The Blended Sample HLS and DMS Pilot Plant test results are expected in early January 2025.

About Dense Media Separation (DMS)

Dense Media Separation ("DMS") is a relatively simple and inexpensive method of pre-concentrating mineralization before it enters the Grinding and Flotation Circuits at the Scotia Mine. It has been used extensively worldwide on many types of minerals, including projects similar to the Scotia Mine. After crushing, the material is processed through cyclones typically using a ferro-silicon media that will allow non-mineralized rock to "float" and be collected as waste, while mineralized material will "sink" and be directed to the grinding circuit as higher graded mill feed. EDM already has a 2,700 tonnes per day mill concentrator on site at the Scotia Mine, so a DMS plant could be added prior to the Flotation Circuit in the existing processing building.

Mr. Curtis Mohns, P.Eng., Senior Metallurgist for SGS Laboratories and a Qualified Person as defined under NI43-101, has approved the technical information contained in this news release related to the HLS test work.

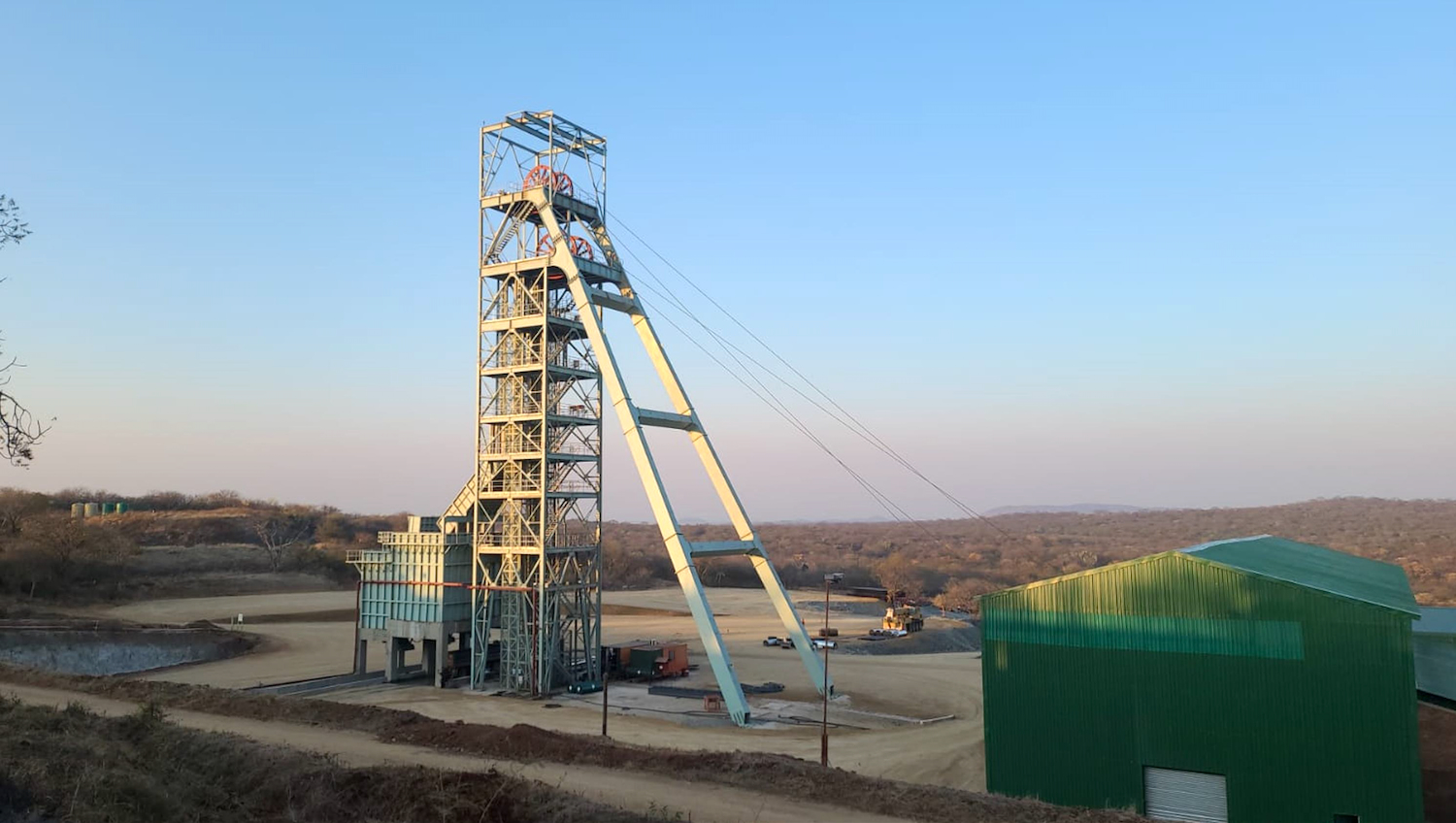

About EDM Resources Inc.

EDM is a Canadian exploration and mining company that has full ownership of the Scotia Mine and related facilities near Halifax, Nova Scotia. Through its wholly owned subsidiary, EDM also holds several prospective exploration licenses near its Scotia Mine and in the surrounding regions of Nova Scotia.

The Company's common shares are traded on the TSX Venture Exchange under the symbol "EDM". For more information, please contact:

Mark Haywood President & Chief Executive Officer

Arnab De Chief Financial Officer

Manish Grigo Corporate Development

Telephone +1 (902) 482 4481Facsimile +1 (902) 422 2388Email & Web [email protected] & www.EDMresources.com

The Company's corporate filings and technical reports can be viewed on the Company's SEDARPLUS profile at www.sedarplus.ca. Further information on EDM is also available on Facebook at http://www.facebook.com/EDMresources.inc Twitter at http://www.twitter.com/EDMresources and LinkedIn at http://www.linkedin.com/company/EDMresources.

CAUTIONARY STATEMENTS

Neither the TSX Venture Exchange nor its Regulation Services Provider(as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this news release.

This news release includes certain forward-looking statements which are not comprised of historical facts. Forward-Looking statements include estimates and statements that describe the Company's future plans, objectives or goals, including words to the effect that the Company or management expects a stated condition or result to occur. Forward-Looking statements may be identified by such terms as "believes", "anticipates", "expects", "estimates", "may", "should", "could", "would", "will", or "plan". Since forward-looking statements are based on assumptions and address future events and conditions, by their very nature they involve inherent risks and uncertainties. Although these statements are based on information currently available to the Company, the Company provides no assurance that actual results will meet management's expectations. Risks, uncertainties, and other factors involved with forward-looking information could cause actual events, results, performance, prospects, and opportunities to differ materially from those expressed or implied by such forward-looking information. Forward-Looking information in this news release includes, but is not limited to, the Company's objectives, goals or future plans, statements, potential mineralization, exploration and development results, the estimation of mineral resources, exploration and mine development plans, timing of the commencement of operations and estimates of market conditions. There can be no assurance that forward-looking statements will prove to be accurate and actual results and future events could differ materially from those anticipated in such statements. Important factors that could cause actual results to differ materially from EDM's expectations include, among others, the degree to which mineral resource and reserve estimates are reflective of actual mineral resources and reserves, the degree to which factors are present which would make a mineral deposit commercially viable, the price of zinc, lead and gypsum, uncertainties relating to availability and costs of financing needed in the future, changes in equity markets, risks related to international operations, the actual results of current exploration activities, delays in the development of projects, conclusions of economic evaluations and changes in project parameters as plans continue to be refined as well as future prices of metals, ability to predict or counteract potential impact of COVID-19 coronavirus on factors relevant to the Company's business, as well as those factors discussed in the section entitled "Risk Factors" in EDM's management's discussion and analysis of the Company's annual financial statements for the period ended December 31, 2023. Although EDM has attempted to identify important factors that could cause actual results to differ materially, there may be other factors that cause results to be not as anticipated, estimated or intended. There can be no assurance that such statements will prove to be accurate as actual results and future events could differ materially from those anticipated in such statements. Accordingly, readers should not place undue reliance on forward-looking statements.

NOT FOR DISTRIBUTION TO U.S. NEWSWIRE SERVICES OR FOR DISSEMINATION IN THE UNITED STATES

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/236109