Updated RAM Resource Offers Opportunity to Extend ICO Mine Life

(via TheNewswire)

Australia - TheNewswire - 19 April 2023 - Jervois Global Limited (“Jervois” or the “Company”) (ASX:JRV) (TSX-V:JRV) (OTC:JRVMF) advises an updated (April 2023) Mineral Resource Estimate (“MRE”) for its 100% owned Idaho Cobalt Operations (“ICO”) in the United States (“U.S.”) is now complete and surmised below.

Highlights

-

2023 updated Mineral Resource Estimate (“MRE”) for the RAM deposit at the Idaho Cobalt Operations (“ICO”) incorporates 10,000 metres (“m”) of new drilling comprising six (6) resource expansion drillholes and sixty-two (62) infill drillholes1

-

Updated ICO Measured and Indicated (“M”) MRE at 3.78 million metric tonnes (“Mt”) grading 0.52% cobalt (“Co”), 0.84% copper (“Cu”) and 0.54 grams per metric tonne of gold (“g/t Au”), reported at a cut-off grade (“CoG”) of 0.20% Co; update broadly consistent with previous (2020) MRE

-

Updated Inferred Resources increased grade, relative to the previous (2020) MRE, with updated tonnage of 1.59Mt @ 0.51% Co, 0.92% Cu and 0.65 g/t Au; at a 0.20% Co CoG. Co, Cu and Au grades improved 21%, 84% and 18%, respectively

-

Inferred Resources represent significant opportunity with respect to resource/reserve development through potential conversion to MI classification with further drilling

-

RAM orebody remains open at depth and along strike; Jervois has identified Exploration Targets beyond the limits of the current MRE that represent between 0.5-0.7Mt of mineralisation ranging from 0.63% to 0.79% Co, 0.69% to 0.79% Cu and 0.45 to 0.53 g/t Au

-

Drilling results provide confidence that the updated RAM resource has potential to ultimately support extended mine life when utilised to update Mineral Reserves and incorporated into a revised Life of Mine plan

-

United States (“U.S.”) Department of Defense (“DOD”) intends to award Jervois US$15 million under Defense Production Act (“DPA”) Title III programme; proceeds can accelerate drilling, aimed at increasing ICO mineral resource and reserve, and assess construction of a cobalt refinery in the U.S.; both can proceed as planned despite the recently announced suspension of the ICO mine2

Mineral Resources

An updated MRE for the RAM deposit is presented below (Tables 1 and 2) at a series of cut-off grades (“CoGs”) that includes a 0.15% Co CoG, which was the reported CoG for the previous 2020 MRE, as well as the 0.20% Co CoG that has been selected for current reporting, due to a revised evaluation of anticipated mining and processing costs.

The global resource (mineralised envelope) comprising the RAM deposit at ICO remains open both at depth and along strike. Jervois is confident there is significant continued potential for resource expansion. Encouragingly, the 10,000 metres (“m”) of new drilling completed since the previous (2020) ICO MRE, has increased both statistical and geological confidence based on the consistency of the new drilling results. In particular, no significant offsets or other grade discontinuities were identified.

The current ICO mineral resource estimation work incorporates revised geological modelling that more accurately represents Co-Cu mineralisation within the RAM deposit. The revised modelling approach, along with modified resource categorisation criteria, has resulted in a minor decrease in tonnage (-11%) of the 2023 total Measured and Indicated (“M&I”) resources relative to the previous (2020) MRE. However, these changes have also resulted in corresponding increases in Co and Cu grades of +6% and +12%, respectively. Figures further illustrating the comparison between the previous (2020) and the current ICO MRE are presented below (Figures 1-4).

Table 1: Measured and Indicated Mineral Resources (Inclusive of Mineral Reserves)

|

Measured and Indicated Mineral Resources (Inclusive of Mineral Reserves) |

|||||||||||||||

|

2023 MRE |

2020 MRE |

||||||||||||||

|

Co Cut-off (%) |

Metric tonnes |

Co (%) |

Co (lbs) |

Cu (%) |

Cu (lbs) |

Au (g/t) |

Au (Oz*) |

Metric tonnes |

Co (%) |

Co (lbs) |

Cu (%) |

Cu (lbs) |

Au (g/t) |

Au (Oz*) |

|

|

0.15 |

4,350,000 |

0.48 |

45,750,000 |

0.79 |

76,270,000 |

0.50 |

70,354 |

5,230,000 |

0.44 |

50,100,000 |

0.69 |

80,060,000 |

0.53 |

89,260 |

|

|

0.20 |

3,780,000 |

0.52 |

43,540,000 |

0.84 |

69,820,000 |

0.54 |

65,299 |

4,260,000 |

0.49 |

46,300,000 |

0.75 |

70,080,000 |

0.60 |

82,300 |

|

|

0.25 |

3,260,000 |

0.57 |

40,990,000 |

0.87 |

62,680,000 |

0.57 |

59,447 |

3,500,000 |

0.56 |

42,600,000 |

0.79 |

61,270,000 |

0.65 |

73,220 |

|

|

0.30 |

2,780,000 |

0.62 |

38,110,000 |

0.92 |

56,180,000 |

0.61 |

54,211 |

2,920,000 |

0.61 |

39,100,000 |

0.83 |

53,620,000 |

0.68 |

64,220 |

|

|

0.35 |

2,410,000 |

0.67 |

35,420,000 |

0.95 |

50,330,000 |

0.64 |

49,390 |

2,440,000 |

0.66 |

35,600,000 |

0.86 |

46,520,000 |

0.73 |

57,450 |

|

*Troy ounce

Table 2: Inferred Mineral Resources

|

Inferred Mineral Resources |

|||||||||||||||

|

2023 MRE |

2020 MRE |

||||||||||||||

|

Co Cut-off (%) |

Metric tonnes |

Co (%) |

Co (lbs) |

Cu (%) |

Cu (lbs) |

Au (g/t) |

Au (Oz*) |

Metric tonnes |

Co (%) |

Co (lbs) |

Cu (%) |

Cu (lbs) |

Au (g/t) |

Au (Oz*) |

|

|

0.15 |

1,940,000 |

0.45 |

19,330,000 |

0.83 |

35,550,000 |

0.58 |

36,156 |

1,570,000 |

0.35 |

12,000,000 |

0.44 |

13,820,000 |

0.45 |

22,490 |

|

|

0.20 |

1,590,000 |

0.51 |

17,990,000 |

0.92 |

32,250,000 |

0.65 |

33,053 |

1,110,000 |

0.42 |

10,300,000 |

0.50 |

11,100,000 |

0.55 |

19,520 |

|

|

0.25 |

1,370,000 |

0.56 |

16,880,000 |

0.98 |

29,660,000 |

0.69 |

30,558 |

830,000 |

0.49 |

8,900,000 |

0.56 |

9,300,000 |

0.62 |

16,380 |

|

|

0.30 |

1,160,000 |

0.61 |

15,580,000 |

1.05 |

26,800,000 |

0.75 |

27,885 |

610,000 |

0.57 |

7,600,000 |

0.65 |

7,930,000 |

0.72 |

14,070 |

|

|

0.35 |

970,000 |

0.67 |

14,280,000 |

1.09 |

23,420,000 |

0.80 |

24,877 |

450,000 |

0.65 |

6,400,000 |

0.71 |

6,390,000 |

0.72 |

10,500 |

|

*Troy ounce

Table 3: ICO Underground Constrained Mineral Resource Estimate @ 0.20% Co CoG

|

Classification |

Tonnes |

Co (%) |

Co (lbs) |

Cu (%) |

Cu (lbs) |

Au (g/t) |

Au (Oz*) |

|

Measured |

460,000 |

0.70 |

7,100,000 |

1.16 |

11,800,000 |

0.783 |

11,500 |

|

Indicated |

3,320,000 |

0.50 |

36,500,000 |

0.79 |

58,000,000 |

0.504 |

54,000 |

|

M&I |

3,780,000 |

0.52 |

43,600,000 |

0.84 |

69,800,000 |

0.538 |

65,500 |

|

Inferred |

1,590,000 |

0.51 |

18,000,000 |

0.92 |

32,300,000 |

0.645 |

33,000 |

*Troy ounce

Notes:

-

Mr. Andrew Turner, P.Geol. of APEX Geoscience Ltd., a Qualified Person as defined by NI 43-101 and a Competent Person as defined by JORC, is responsible for the completion of the updated mineral resource estimation, with an effective date of April 1, 2023.

-

Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

-

The estimate of Mineral Resources may be materially affected by environmental, permitting, legal, title, taxation, socio-political, marketing, or other relevant issues.

-

The Inferred Mineral Resource in this estimate has a lower level of confidence than that applied to an Indicated Mineral Resource and must not be converted to a Mineral Reserve. It is reasonably expected that the majority of the Inferred Mineral Resource could potentially be upgraded to an Indicated Mineral Resource with continued exploration.

-

The Mineral Resources were estimated in accordance with the Canadian Institute of Mining, Metallurgy and Petroleum (“CIM”), CIM Standards on Mineral Resources and Reserves, Definitions (2014) and Best Practices Guidelines (2019) prepared by the CIM Standing Committee on Reserve Definitions and adopted by the CIM Council.

-

The cut-off grade of 0.20% Co is based on an estimated process cost and GA cost of US$123.17/t, and metal prices of US$25.00/lb Co, US$3.00/lb Cu, and US$1750/troy oz Au, with process recoveries of 91.0% Co, 95.4% Cu, and 84.9% Au. An average contribution of 22% to Co payable values from Cu and Au has been assumed based upon the relative concentrations of the payable metals within the reported MI resources.

-

The reported mineral resources are constrained by manually created wireframe solids (mineable shapes) that encapsulate contiguous blocks demonstrating reasonable prospects for eventual economic extraction within the minable shapes.

Estimation parameters used to calculate the new 2023 ICO MRE are discussed in greater detail below and differ in a number of ways from those used in the 2020 ICO MRE. The current MRE uses 4-ft composites, while the historical MRE utilized 2-ft composites. Density data is also handled differently, as the current MRE utilizes single density values for each estimation domain based upon a statistical analysis of the individual density measurements contained within each domain. In comparison the 2020 MRE used a Co+Cu linear regression equation and the available density measurement data to estimate a density value for each composite. Estimation methodologies differ as well with the updated MRE utilising ordinary kriging and the 2020 MRE employing inverse distance squared.

As discussed above, the slight decrease in the total 2023 M&I resource tonnage, relative to the 2020 MRE, was accompanied by modest Co and Cu grade increases that have resulted in only a minor decrease in contained Co (-6%) and effectively no change in the contained Cu. In combination there was a significant increase in the 2023 Inferred MRE tonnage at ICO, relative to the 2020 MRE, increasing tonnes by more than 40%, up to 1.59Mt @ 0.51% Co, 0.92% Cu, 0.65 g/t Au. This gain in Inferred resources was largely driven by results of the 2,300m of resource expansion drilling completed in 2022 that tested down-dip extents of the RAM deposit. The RAM orebody remains open at depth, and also along strike.

Figure 1: 2023 vs 2020 MRE M&I Resource Tonnage Comparison

Figure 2: 2023 vs 2020 MRE M&I Resource Contained Cobalt Comparison

Figure 3: 2023 vs 2020 MRE Inferred Resource Tonnage Comparison

Figure 4: 2023 vs 2020 MRE Inferred Resource Contained Cobalt Comparison

The Company’s long-term forecasted metal prices, used for the evaluation of the reporting cut-off grade for the 2023 MRE, remain unchanged from those utilized in the 2020 ICO MRE and Bankable Feasibility Study (“BFS”), which are tabulated below (along with 2-year and 3-year trailing average metal prices for comparison).

Table 3: US$ Metal Prices for Resource CoG Determination

|

Metal |

Values (US$) |

Unit |

|

Cobalt |

$25.00 |

/lb |

|

Copper |

$3.00 |

/lb |

|

Gold |

$1,750 |

/tr.oz. |

|

Metal |

2 Year Average |

3 Year Average |

|

Cobalt/lb |

$28.28 |

$24.47 |

|

Copper/lb |

$4.12 |

$3.68 |

|

Gold/tr. oz |

$1,800 |

$1,792 |

Resource expansion work at ICO has focussed on down-dip extension of the RAM deposit, targeting beneath the central and southern extents of the 2020 MRE. Recent resource expansion drilling extended the vertical extents of the RAM deposit within targeted zones between 115m and 215m down-dip to an elevation of approximately 1,750m (see Figure 5).

Figure 5: RAM Resource Long Section

Future expansion drilling will focus on expanding the Indicated and Inferred depth continuity of the RAM MRE down-dip of the deposit’s central zone and along strike to the north.

In-fill drilling within the 2020 M&I Resources has provided strong indications of continuity in mineralisation across the south-central to central domains of the RAM deposit, which has increased confidence that is reflected in the estimation methodology implemented in production of the current MRE. Additional definition drilling available to the MRE has also increased confidence along the deposit margins, resulting in a greater level of accuracy across all resource categories. Furthermore, the geological continuity established within the updated M&I Resources of the RAM deposit provides confidence with respect to the mineability of the orebody due to the observed absence of significant offsets, gaps or other grade discontinuities. This is also likely to benefit an ability to upgrade newly defined Inferred Mineral Resources in an effort to extend mine life at ICO.

As noted previously, the RAM deposit remains open at depth and along strike to the north. As a result, JORC Exploration Targets proximal to the updated RAM deposit MRE have been identified that range between 0.5 and 0.7Mt with anticipated grades ranging from 0.63% to 0.79% Co, 0.69% to 0.79% Cu and 0.45 g/t to 0.53 g/t Au. These Exploration Targets are located between 100m and 150m from existing drillhole intercepts along the periphery of the current RAM deposit, an examination of which was used to establish the estimated ranges of tonnages and grades. This represents further upside potential for mine life expansion at the ICO, although it should be noted that Exploration Targets are conceptual in nature, with insufficient exploratory data to be included as part of a formal MRE, and are thus not included with the currently reported ICO MRE3.

MRE Methodology

Modelling was conducted in local Mine Grid coordinates (in US feet). The MRE block model utilised a rotated block size of 12 ft (X) x 12 ft (Y) x 4 ft (Z) to honour the mineralisation wireframes. The percentage of the volume of each block below the bare earth surface and within each mineralisation domain was calculated using 3D geological models and a 3D surface model.

The ICO drillhole database consists of 158 drillholes that intersect the interpreted mineralisation wireframes. The Co, Cu, and Au assays were composited to 4-foot composite lengths and the estimation utilised 1469 composited samples. A total of 0.4% of the total drilled metres inside the interpreted mineralisation wireframes were not sampled, assumed to be waste, and assigned a nominal waste value of half the detection limit of modern assay methods (0.005 % Co, 0.005 % Cu, 0.0005 g/t Au).

Estimation of Co, Cu, and Au grades was completed using Ordinary Kriging. The search ellipsoid size used to estimate each metal was defined by the modelled variograms. Block grade estimation employed locally varying anisotropy, which uses different rotation angles to define the principal directions of the variogram model and search ellipsoid on a per-block basis. Blocks within estimation domains are assigned rotation angles using a modelled 3D mineralisation trend surface wireframe, which allows structural complexities to be reproduced in the estimated block model. The number of variogram structures, contributions of each structure, and their ranges are set per estimation domain and do not vary within the estimation domain.

A total of 3466 bulk density samples are available from the ICO drillhole database, of which, 639 are within the modelled estimation domains. Jervois’s geological adviser, APEX Geoscience Ltd (“APEX”) performed exploratory data analysis of the bulk density samples available and the density was assigned for each domain at the ICO. The density of the deposits ranged from 2.86 g/cm3 to 3.11 g/cm3. The non-mineralised country rock was assigned a density of 2.83 g/cm3.

There are no other factors or issues of which the JORC Competent Person (“CP”), NI 43-101 Qualified Person (“QP”), is aware that would materially affect the current ICO MRE other than normal risks faced by all mining projects. The ICO is subject to the same types of risks that large base metal projects experience at an early stage of development in U.S.. The nature of the risks relating to ICO will change as the mine evolves and more information becomes available. The Company has engaged experienced management and specialized consultants to identify, manage and mitigate those risks.

U.S. Department of Defense Award Status

As previously announced, the U.S. Department of Defense (the “DOD”) has advised that it intends to award Jervois an immediate need for Defense Production Act (“DPA”) Title III with US$15 million of funding through a Not to Exceed Technology Investment Agreement. The DOD award would be subject to Jervois successfully completing required documentary steps including agreement to terms and conditions of the award. These steps continue to advance towards completion.

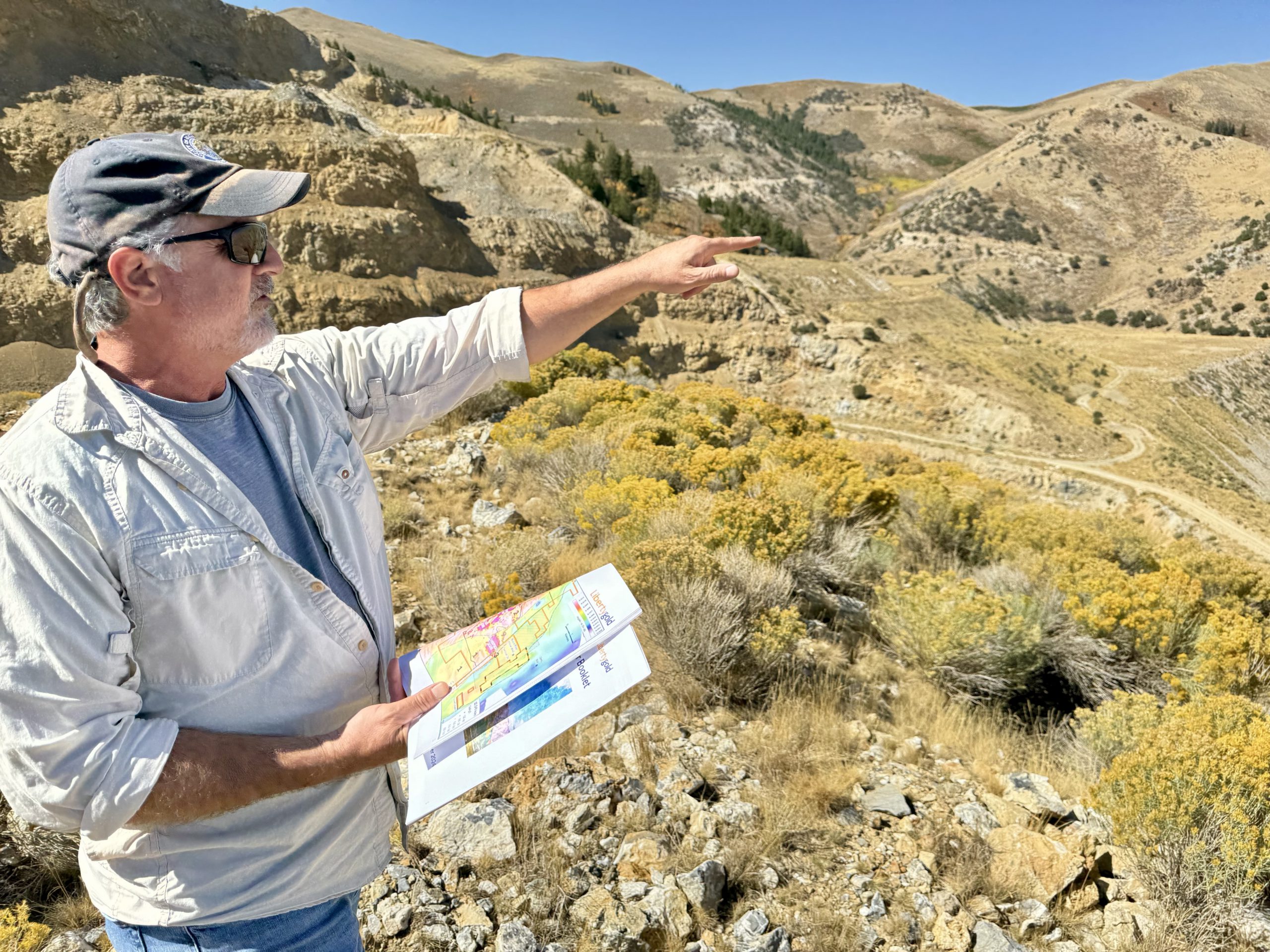

Whilst ICO site has been demobilised and Jervois’ Salmon workforce restructured, the Company’s local geology team has been retained, and it is preparing to remobilise once DOD award monies are available. Detailed 2023 drilling plans have been prepared and the Company stands ready to execute in partnership with the U.S. Government to ensure that ICO can meaningfully contribute to improving the robustness of the U.S. critical mineral supply chain as it pertains to cobalt. ICO continues to offer potential to contribute in managing both U.S. energy transition and national security risks.

Quality Assurance

All drill core samples are sent to ALS Global Laboratories (Geochemistry Division), an independent and fully accredited laboratory (ISO 9001:2008), in Vancouver, Canada, for analysis for gold by Fire Assay and multi-element Induction Coupled Plasma Spectroscopy. Jervois employs a regimented Quality Assurance, Quality Control (“QA/QC”) program where at least 10% duplicates, blanks and certified reference material are inserted into each sample shipment. An examination of the QA/QC data associated with the recent resource expansion and in-fill drilling completed at the ICO was conducted by APEX as part of its initial drilling database validation work and no issues were identified.

On behalf of Jervois Global Limited

Bryce Crocker, Chief Executive Officer

For further information, please contact:

|

Investors and analysts: James May Chief Financial Officer Jervois Global |

Media: Nathan Ryan NWR Communications Mob: +61 420 582 887 |

Competent Person’s Statement

The information in this release that relates to Mineral Exploration is based on information compiled by Andrew Turner, P.Geol. who is a consultant for the company and a member of The Association of Professional Engineers and Geoscientists of Alberta. Andrew Turner has sufficient experience which is relevant to the style of mineralisation and type of deposit under consideration and to the activity which he is undertaking to qualify as a Competent Person as defined in the 2012 Edition of the ‘Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves’. Andrew Turner consents to the inclusion in the release of the matters based on the information in the form and context in which it appears.

Qualified Person’s Statement

The technical content of this news release has been reviewed and approved by Andrew Turner, P.Geol., a consultant for the Company and a Qualified Person as defined by National Instrument 43-101.

Forward-Looking Statements

This news release may contain certain “Forward-Looking Statements” within the meaning of the United States Private Securities Litigation Reform Act of 1995 and applicable Canadian securities laws. When used in this news release, the words “anticipate”, “believe”, “estimate”, “expect”, “target, “plan”, “forecast”, “may”, “schedule”, “expected” and other similar words or expressions identify forward-looking statements or information. These forward-looking statements or information may relate to conversion of Inferred Mineral Resources to Measured and Indicated Mineral Resources at ICO, the outcome of future drilling program, timing of updated Mineral Reserves, the mine life of ICO and certain other factors or information. Such statements represent Jervois’ current views with respect to future events and are necessarily based upon a number of assumptions and estimates that, while considered reasonable by Jervois, are inherently subject to significant business, economic, competitive, political and social risks, contingencies and uncertainties. Many factors, both known and unknown, could cause results, performance or achievements to be materially different from the results, performance or achievements that are or may be expressed or implied by such forward-looking statements. Jervois does not intend, and does not assume any obligation, to update these forward-looking statements or information to reflect changes in assumptions or changes in circumstances or any other events affections such statements and information other than as required by applicable laws, rules and regulations.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Appendix 1:

JORC Code, 2012 Edition – Table 1

Section 1 Sampling Techniques and Data

|

Criteria |

JORC Code explanation |

Commentary |

|

Sampling techniques |

|

All drill core was sampled contingent on geology and core recovery: Core was collected directly from the core barrel into core boxes, and drill core was cut in half by diamond saw, with one half of the core collected for laboratory analysis and the other half retained as reference core in the tray. Core trays were clearly labelled with the hole number, tray number and depth intervals marked. A “cut-line” was drawn by the logging geologists along the length of the drill core as a guide for the core sawing. The half-core was sampled, ensuring that the same side is consistently sampled, and placed into sample bags labelled with the assigned sample number. Downhole measurements are recorded using a Reflex OMNI Gyro at 30 metre intervals down each hole and at 1.5 metre intervals continuously at the end of every hole. Field sampling followed Jervois protocols including industry standard quality control procedures. Samples were sent to: ALS Geochemistry-Vancouver, an independent and fully accredited laboratory in Vancouver, Canada (“ALS”) for analysis for gold by 30g Fire Assays with wet chemical finish (ICP) and by multi-element Induction Coupled Plasma Spectroscopy (“ICP”). Jervois also has a regimented Quality Assurance, Quality Control (“QA/QC”) program where at least 10% standards and blanks are inserted into each sample shipment.

Diamond Core: core samples are “representative” (and not “selective”) in that each sample comprised half (cut) core that was collected along the entire length of each sample interval. Handheld XRF instruments were used to spot check drill core for mineralization, however those results were not relied on. All sample results reported on are from ALS, an independent laboratory. All of the drilling was diamond drill core (HQ/NQ). Typically, drill core was sampled on nominal 3 foot (~1m) half core samples for HQ/NQ. All sample analyses were completed at ALS . ALS operates independent laboratories globally, which are ISO accredited. Samples are received at the laboratory: Bar codes are scanned and logged; samples are weighed and dried; samples are crushed to 70% less than 2mm, the crushing product is riffle split to collect a 250g split, which is pulverized to better than 85% passing 75 microns; aliquots from the pulverized split (the sample “pulp”) are analysed for 34 elements using ICP analysis and for gold by 30 gram Fire Assay with ICP-AES finish. Any samples with initial “over-limit” results for specific metals, including gold, copper, cobalt and arsenic are re-analysed accordingly to achieve complete results. |

|

Drilling techniques |

|

The 2022 underground drilling comprised HQ and NQ sized core, with reduction of hole size where appropriate. Holes were generally angled from -55 to -90 degrees at varying azimuths. |

|

Drill sample recovery |

|

All holes are logged for basic geotechnical characteristics including measurements and calculations for core recovery and RQD values. Core recovery is recorded as a percentage equivalent to the length of core recovered, as a percentage of the drill run (interval length). Excellent recoveries were obtained from the 2022 diamond drilling. There is no bias noted between sample recovery and grade. Excellent recoveries were obtained from Diamond drilling other than in faulted zones which were not sampled. |

|

Logging |

|

Diamond drilling: Drill core is photographed and logged prior to sampling; Core has been geologically and geotechnically logged to a level of detail appropriate to support mineral resource estimation and mining studies. Logging has been conducted both qualitatively and quantitatively; full description of lithologies, alteration and comments are noted, as well as percentage estimates on veining and sulphides. The total length of all holes drilled in 2022 was 10,302m. All depths of relevance to this release are listed in the table in the body of the text. All drillholes are logged in their entirety. |

|

Sub-sampling techniques and sample preparation |

|

All core was half-cut lengthwise using a diamond saw. The HQ/NQ core half-core was sampled. Samples are received at the laboratory: sample ID bar codes are scanned and logged; samples are weighed and dried; samples are crushed to 70% less than 2mm, the crushing product is riffle split to collect a 250g split, which is pulverized to better than 85% passing 75 microns; aliquots from the pulverized split (the sample “pulp”) are analysed for 34 elements using ICP analysis and for gold by 30 gram Fire Assay with ICP-AES finish. Any samples with initial “over-limit” results for specific metals, including gold, copper, cobalt and arsenic are re-analysed accordingly to achieve complete results. For core sampling the same side is consistently sampled, half-core is retained in the tray for HQ/NQ. The assay sub- sample is placed into sample bags labelled with the assigned sample number. One in 20 samples is duplicated where the core is quartered and a quarter cut sample is analysed as a duplicate. The remaining quarter samples is retained in the tray. Sample sizes of 2-3 kg are appropriate for the grain size of material. The sample preparation technique and sample sizes are considered appropriate to the material being sampled. |

|

Quality of assay data and laboratory tests |

|

The ICP-AES and Fire Assay (30 gram) analytical techniques are considered total and are high quality and appropriate for the mineralization being tested. Jervois has a regimented Quality Control protocol which has consisted of systematic submission of blanks, standards and duplicates in addition to those conducted at the laboratory. Precision levels for all blanks, standards and duplicate samples fell within acceptable ranges. |

|

Verification of sampling and assaying |

|

Significant intersections are alternatively verified by the CP and QP of the company. No holes have been twinned in this drill programme. Data is collected using a PostGRE SQL database custom-built for Idaho Cobalt Operations and incorporates historic MS Excel templated data. The database software includes data validation algorithms. The database software also allows for the direct importation of digital data files from the laboratory. Data is backed up on the cloud hosted server on and off site. All assay/analytical data returning “below detection limit” results have been entered in the project database as one half of the detection limit value. Samples received damaged at the laboratory, or with insufficient sample weight for analysis had the interval or location left blank. |

|

Location of data points |

|

All surface drilling collars were surveyed by licensed surveyors and by trained geologists in the underground. Down-hole surveys were routinely carried out on all holes using a Reflex OMNI Gyro at 30 metre intervals down each hole and at 1.5 metre intervals continuously at the end of every hole. Holes were setup on collar using a Reflex TN14 Gyro. All datum is collected and recorded in a localized ICO Mine Grid. The 3D location of the individual samples is considered to be adequately established, consistent with accepted industry standards. |

|

Data spacing and distribution |

|

To date, due to the exploratory nature of the drilling, the spacing is wide. Assay results for only two holes have been received. Further intervals have been sampled but the assays are not yet available. The intervals released are proximal to the existing RAM deposit MRRE and are interpreted as representing an extension of the RAM deposit. As a result, this data, along with the results from the 4 remaining holes with pending analyses, will be used in a planned mineral resource update later this year. The reported drillhole data comprises length-weight averaged core interval grade values. Data compositing is completed during Mineral Resource Estimation, but has not been applied to the data reported in this release. |

|

Orientation of data in relation to geological structure |

|

Drilling sections are orientated perpendicular to the strike of the host rocks. Drillholes were inclined between -55° and -90° to optimize intercepts of mineralisation with respect to thickness and distribution. Drilling with angled holes in most instances provides a representative sample across the stratigraphy. |

|

Sample security |

|

All individual samples are placed in plastic sample bags sealed with a cable tie. Then groups of samples are bagged in poly-woven sacks also sealed with a cable tie. The samples are sent by courier to the lab and tracked. To date, no sample shipments have had reported problems and/or a breach in security. |

|

Audits or reviews |

|

Jervois protocols consist of a regimented internal QA/QC which match or exceed global industry standards. APEX Geoscience Ltd. has been retained as independent geological consultants and have reviewed and approved the ICO sampling protocols and procedures and will be conducting a thorough review of the drill data, including the QA/QC data, prior to the initiation of resource update. |

Section 2 Reporting of Exploration Results

|

Criteria |

JORC Code explanation |

Commentary |

|

Mineral tenement and land tenure status |

|

ICO consists of 358 unpatented mineral claims totalling 7390 acres. The claims are 100% owned by Jervois subsidiary Jervois Mining USA Ltd. and are in good standing. Unpatented Mineral Claims: Ownership of unpatented mining claims in the U.S. is in the name of the holder, with ownership of the minerals belonging to the United States of America, under the administration of the U.S. Bureau of Land Management. Under the Mining Law of 1872, which governs the location of unpatented mining claims on federal lands, the locator has the right to explore, develop and mine minerals on unpatented mining claims without payments of production royalties to the federal government. Annual claim maintenance and filing fees paid before September 1st each year are the only federal encumbrances to unpatented mining claims. Exploration plans are permitted and administered by the Unites States Forestry Service. The United States Department of Agriculture Salmon Challis National Forest (the Forest Service) issued a revised Record of Decision (the “ROD”) for the ICO in January 2009. The ROD described the decision to approve a Mine Plan of Operations (“MPO”) for mining, milling and concentrating mineralized material from the ICO. The ROD was subsequently affirmed by the Forest Service in April 2009. The Plan of Operations at the ICO mine and mill remained unchanged and the ROD remains in place. In December 2009, the Forest Service approved the MPO allowing for the commencement of ICO construction. There are no known encumbrances. |

|

Exploration done by other parties |

|

The ICO came under Jervois management following the merger with eCobalt in 2019. Prior to this merger, the area has a long history of copper and cobalt exploration and mining. Copper mineralization in the Blackbird Creek area was discovered in 1892, and the area was soon explored as both a copper and gold prospect. The area was first mined by Union Carbide at the Haynes-Stellite Mine located south of the present ICO claim block, during World War I. Union Carbide mined approximately 4,000 tons of cobalt-bearing ore before ceasing operations. From 1938 to 1941, the Uncle Sam Mining and Milling Company operated a mine at the south end of the present Blackbird mine and reportedly mined about 3,600 tons of ore. Calera Mining Company, a division of Howe Sound Company, developed and mined the Blackbird deposit between 1943 and 1959 under a contract to supply cobalt to the U.S. government. Calera stopped mining when the government contract was terminated in 1960. Machinery Center Inc. mined from the district between 1963 and 1966, when Idaho Mining Company (owned by Hanna Mining Company) purchased the property. Noranda optioned the property from Hanna in 1977 and carried out extensive exploration, mine rehabilitation and metallurgical testing. In 1979 Noranda and Hanna formed the Blackbird Mining Company (BMC) to develop the property. BMC completed an internal feasibility study of their property at the time, including material from the Sunshine deposit in 1982. BMC allowed perimeter claims to lapse in 1994, and eCobalt restaked much of that ground. From 1995 to the present, eCobalt completed surface geochemical sampling and drilled 158 diamond drillholes on the ICO ground. |

|

Geology |

|

Deposit Types: Whilst the deposits in the Idaho Cobalt Belt have been studied over many years the deposit types are still a subject of debate. Prior to 2005 the overriding opinion was that the deposits are sedimentary exhalative and are referred to as the Blackbird Sediment Hosted Cu-Co. And have been described as stratabound iron-, cobalt-, copper-, and arsenic-rich sulphide mineral accumulations in nearly carbonate-free argillite/siltite couplets and quartzites. Post 2005 the discovery of high concentrations of rare earth elements (“REE”) lead to the postulation that the deposits are not volcanogenic massive sulphide or sedimentary exhalative deposits but instead are iron oxide-copper-gold (“IOCG”) deposits. Geological Setting: The ICO is situated in the Idaho Cobalt Belt, a 50- to 55-kilometre long metallogenic district characterized by stratiform/tabular copper-cobalt deposits. The deposits are hosted by a thick, dominantly clastic sequence of Middle Proterozoic age sandwiched between late Proterozoic quartz monzonitic intrusions. The clastic sediments were deposited in a large fault-bounded basin, probably as large submarine fan complexes and/or deltaic aprons that were frequently “drowned” by continuing subsidence within the basin. All significant copper-cobalt deposits and occurrences are found in the Proterozoic Apple Creek Formation, which constitutes the base of this sequence. This formation was originally correlated with Pritchard Formation metasediments of the Belt supergroup to the north, its age being constrained by dates of 1.37 Ga for adamellites intruding the sequence and 1.7 Ga from mafic dykes and sills emplaced along the basin margin faults. The structure of the Apple Creek Formation is dominated by the regional rift structure. Cobalt-copper-gold mineralization occurs along a northwest-southeast trending structure parallel to and west of the central axis of the rift. There is a series of northerly trending faults that are considered to represent initial growth faults, reactivated by Laramide and younger events. The district has also been affected by north-easterly structures of the Trans-Challis Fault Zone. The ICO is hosted in Proterozoic age meta-sediments found on the east side of the central Idaho Batholith comprising granitic-to-granodioritic rocks. The Idaho Cobalt Belt represents a distinct district dominated by stratabound cobalt + copper ± gold mineralization, with a remobilized constituent. The district is underlain by strata of the middle Proterozoic-age Apple Creek Formation, which is an upward-thickening, upward-coarsening clastic sequence at least 14,900 metre thick that represents a major basin-filling episode and was formerly considered part of the Yellow Jacket Formation. The Apple Creek can be divided into three units. The lower unit of the Apple Creek Formation is over 4,500 metre thick and consists mainly of argillite and siltite, with lesser occurrences of fine-grained quartzite and carbonates. Graded bedding and planar to wavy laminae are common in the lower unit, which is locally metamorphosed to phyllite. The middle unit of the Apple Creek Formation is up to 1,100 metres thick and comprises several upward-coarsening sequences of argillite, siltite, and quartzite, with distinctive biotite-rich interbeds that generally have a direct correlation to mineralization. The middle unit hosts the majority of the known cobalt, copper and gold occurrences in the Idaho Cobalt Belt. The upper unit exceeds 3,000 metres in thickness and is predominantly composed of thin- to thick bedded, very fine- to fine-grained quartzite. Mafic tuffs within the Apple Creek Formation are the oldest igneous rocks exposed in the Sunshine-Blackpine district. They are accompanied by felsic tuffs and carbonatitic tuffs. Some mafic dikes and sills intrude the Apple Creek Formation and may be comagmatic with the mafic tuff beds. Several small lamproitic diatremes may also be coeval with mafic volcanism. The Apple Creek Formation has undergone varying degrees of regional metamorphism, ranging from greenschist facies in the southern part of the district to amphibolite grade facies in the northern part of the district. Several types of mafic dikes and sills, ranging from 1m to 30m thick, intrude the Apple Creek Formation and are interpreted as feeders to the exhalative mafic tuffs, which are most abundant in areas of intrusive activity. Style of Mineralization: Mineralization at the ICO is characterized as syngenetic, stratiform/tabular exhalative deposits within, or closely associated with, the mafic sequences of the Apple Creek Formation. This mineralization is dominantly bedding concordant and the deposits range from nearly massive to disseminated. Some crosscutting mineralization is present that may be in feeder zones to the stratiform mineralization or may be due to remobilization locally into fracture quartz veins and/or crosscutting structures. Dominant minerals include cobaltite (CoAsS) and chalcopyrite (CuFeS2), with lesser, variable occurrences of gold. Other minerals present in small quantities are pyrite (FeS2), pyrrhotite (FeS), arsenopyrite (FeAsS), linnaeite ((Co Ni)3S4), loellingite (FeAs2), safflorite (CoFeAs2), enargite (Cu3AsS4) and marcasite (FeS2). Recently, rare-earth minerals have been identified in samples from the deposit as monazite, xenotime and allanite. At this time, these minerals have not been considered for potential recovery as by-products of the Co-(Cu-Au). The RAM is the largest and best-known deposit in the ICO area. It consists of a Hanging-wall Zone with 3 primary and 4 minor horizons, a Main Zone comprising 3 horizons, and a Footwall Zone with 3 horizons. These sub-parallel horizons generally strike N15oW and dip 50o – 60o to the northeast. Most of the significant Co mineralization is associated with exhalative lithologies i.e. biotitic tuffaceous exhalate (BTE), siliceous tuffaceous exhalate (STE), and quartzite with impregnations of biotitic tuffaceous exhalate (QTZ/BTE) or siliceous tuffaceous exhalate (QTZ/STE). |

|

Drillhole Information |

|

No Exploration data is being reported in this release. |

|

Data aggregation methods |

|

In previous reports weighted averaging has been used in reported composite intervals and individual results are also listed, no grade truncations etc. has been used. Aggregate intercepts are reported using a grade metre calculation. For example: ((assay x meter interval sampled) + (assay x meter interval sampled) + (assay x meter interval sampled) / divided by total number of meters in the interval). Individual sample intercepts are also shown. Calculated true widths determined for the composited intercept mid-point, perpendicular to the down-dip projection of the RAM deposit. No metal equivalent values have been reported. |

|

Relationship between mineralisation widths and intercept lengths |

|

Downhole lengths are reported. |

|

Diagrams |

|

Refer to figures and tables in the body of the text. |

|

Balanced reporting |

|

Calculated true widths determined for the composited intercept mid-point, perpendicular to the down-dip projection of the RAM deposit. |

|

Other substantive exploration data |

|

There is no other substantive exploration data. |

|

Further work |

|

Jervois plans to continue to undertake infill and expansion drilling to upgrade resource categories as well as to test the footwall horizons discovered during the 2019 drill program. |

Section 3 Estimation and Reporting of Mineral Resources

(Criteria listed in section 1, and where relevant in section 2, also apply to this section.)

|

Criteria |

JORC Code explanation |

Commentary |

|||||||||||||||||||||||||||

|

Database integrity |

|

Following data validation checks, APEX deemed the ICO drilling and analytical databases, provided by Jervois, to be suitable for use in the geological modelling and resource estimation work that is the subject of this release. |

|||||||||||||||||||||||||||

|

Site visits |

|

|

|||||||||||||||||||||||||||

|

Geological interpretation |

|

|

|||||||||||||||||||||||||||

|

Dimensions |

|

|

|||||||||||||||||||||||||||

|

Estimation and modelling techniques |

|

|

|||||||||||||||||||||||||||

|

Moisture |

|

|

|||||||||||||||||||||||||||

|

Cut-off parameters |

|

|

|||||||||||||||||||||||||||

|

Mining factors or assumptions |

|

|

|||||||||||||||||||||||||||

|

Metallurgical factors or assumptions |

|

|

|||||||||||||||||||||||||||

|

Environmen-tal factors or assumptions |

|

|

|||||||||||||||||||||||||||

|

Bulk density |

|

|

|||||||||||||||||||||||||||

|

Classification |

|

Measured: 150 x 80 x 23 feet ellipsoid, at least 3 drillholes Indicated: 300 x 160 x 23 feet ellipsoid, at least 2 drillholes Inferred: 400 x 250 x 23 feet ellipsoid, at least 1 drillhole

|

|||||||||||||||||||||||||||

|

Audits or reviews |

|

|

|||||||||||||||||||||||||||

|

Discussion of relative accuracy/ confidence |

|

|

|||||||||||||||||||||||||||

1 See ASX announcements “Jervois drilling de-risks RAM resource” and “Expansion drilling consolidates RAM deposit extension at Jervois’ ICO” dated 8 February 2023 and 20 February 2023 (Australia).

2 See ASX announcement “Jervois suspends final construction at Idaho Cobalt Operations” dated 29 March 2023 (Australia).

3 Exploration targets calculated using density ranging from 2.8 to 2.9 g/cm3 and projected widths ranging from 3 to 4 metres per observed deposit characteristics.

Copyright (c) 2023 TheNewswire - All rights reserved.