Oyu Tolgoi uses ThoroughTec mining simulators for operator training

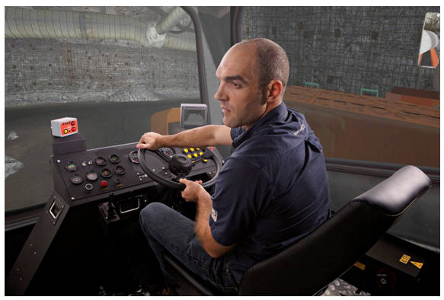

ThoroughTec has announced that the Rio Tinto Limited project in Mongolia – Oyu Tolgoi – will be using their Cybermine mining simulators to enhance operator skill and safety. The full press release is as follows; for more information see the ThoroughTec website at http://www.thoroughtec.com.

OYU TOLGOI MINE IN MONGOLIA OPTS FOR THOROUGHTEC’S CYBERMINE MINING SIMULATORS

Rio Tinto Limited, the diversified mining giant which assumed direct management of Oyu Tolgoi late last year from Ivanhoe Mines, has, after intensive Simulator Supplier evaluations, selected ThoroughTec’s latest generation CYBERMINE4 mining simulators to enhance operator skill and safety.

Richard Storrie, the Technical Services Manager at Oyu Tolgoi, advocated the purchase of the simulators for the mine after witnessing the impressive results attained by Aurora College and Rio Tinto’s Diavik Mine in the Northern Territories, Canada. Aurora College had purchased CYBERMINE simulators back in 2007 and was tasked with providing Diavik Mine with proficient and safe operators. Mr Storrie, an ex-Diavik Mine Manager, immediately recognised the immediate business improvement potential that simulator based training would provide at Oyu Tolgoi.

“Oyu Tolgoi is committed to employee safety and industry best practices. Currently there is excellent integration of mining best practices between the two organisations (Ivanhoe Mines and Rio Tinto Limited) to ensure that best possible standards are adopted and successfully implemented in the Oyu Tolgoi operation. We see employee safety as the number one priority and simulator based training will be one of the key contributors in achieving our goals in this regard.”

“Oyu Tolgoi’s development workforce includes local employees and highly skilled expatriates entrusted with training and supervision. As mine development morphs into full-scale production however, more and more experienced local operators will be needed and Oyu Tolgoi is committed to having a minimum of ninety percent of its workforce employed from the local (Mongolian) community. To effectively train and up-skill these local operators for a mega-mine like Oyu Tolgoi will require specialised training equipment and an exceptional training programme,” said Mr Storrie.

Dr John Waltham, ThoroughTec’s Executive Director says “The initiative taken by Oyu Tolgoi is becoming the norm within the larger mining houses that hold the same high regard for employee safety and skills enrichment. The CYBERMINE4 simulator systems purchased by Oyu Tolgoi will be essential in the rapid transfer of the much needed operator skills and safety habits to the local community, who have very little, if any, exposure to the operation of complex mining machinery. We are confident that the latest generation CYBERMINE4 simulators to be deployed at Oyu Tolgoi in Q3 of this year will again prove to be an unqualified success and a vital cog in the wheel of local skills generation and proficiency optimisation.”

Mr Storrie continues, “In selecting ThoroughTec as our simulator systems provider, there were several essential requirements that had to be considered: Firstly, ThoroughTec’s off-the-shelf product range best matched our OEM equipment used at the mine and their development capability (for new simulator cabs) was deemed best able to support any future OEM equipment purchases. A second very important consideration was system reliability and maintainability – Oyu Tolgoi is in a remote area and this was considered extremely important in selecting the final supplier. ThoroughTec’s ISO 9001 quality management system coupled to the extremely high system reliability and availability experienced at Aurora College gave us the assurance we needed.”

“Our in-house development capability and system reliability is derived from our military engineering background, stringent quality control processes and vast experience in mining simulation. The military and aerospace industries have highly defined simulation standards and we naturally use the same standards to develop our CYBERMINE4 mining simulator product range. We believe quality management control systems, such as the internationally recognised ISO 9001 system, should be a minimum quality requirement in the industry, as mining companies have a right to expect extremely high simulator uptime and low operating and through-life costs” said Dr Waltham.

In addition to purchasing the two containerised simulator base units, Oyu Tolgoi also purchased the following plug-and-play simulator cabs: Atlas Copco Boltec MC Bolter; Sandvik Toro 40D Mine Truck; Sandvik LH517 Loader and a shotcrete sprayer to be based on the Normet Spraymec 1050. The specified cabs have been purposely chosen to cover the primary mining activities at Oyu Tolgoi and will afford all employees valuable experiential training and evaluation following their classroom induction.

Although Oyu Tolgoi has purchased underground mining simulator base units, the operation has both underground and surface mining components. The new CYBERMINE4 range of simulators allow both underground and surface mining simulations in the same base unit, making use of a unique cross-platform adaptor kit. Oyu Tolgoi will therefore still be able to purchase surface mining cabs in the future as the need arises, significantly lowering the total cost of ownership.

To further increase the training experience on the simulators, ThoroughTec will be developing customised CYBERMINE “worlds” which will accurately replicate the tunnel geometry and operating conditions of the mine. Student operators of each of the equipment variants will therefore be familiar with Oyu Tolgoi’s underground mining environment even before venturing underground.

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments