NMC to remain the dominant EV battery cathode type until 2030 – report

The EV battery materials mix will be determined by technological advancements in cathode, anode and electrolyte design, with a particular focus on energy density, cost competitiveness and the sustainability of associated supply chains, says market analyst Fitch Solutions in its latest EV battery chemistry outlook.

LFP uses lithium iron phosphate as cathode material while NMC uses lithium, manganese, and cobalt as cathode material.

Fitch expects the NMC chemistry to remain the dominant EV battery cathode type over its forecast period, (2021- 2030) owing to the superior energy density of high-nickel variations, which improve vehicle range and charging speeds.

The LFP cathode will also gain market share given its low-cost, longer life-cycle and advantageous raw material inputs (no nickel or cobalt) which mitigate supply-side constraints to an extent, Fitch says.

Demand for battery materials will remain elevated as more automakers commit to electrifying an extent of their model-line ups. In the immediate term, the demand outlook for battery materials will be determined by automaker, and by extension consumer demand specifications in Europe, China and the US, which Fitch expects to combine to account for an annualised average of 86.4% of global EV sales over its forecast period.

Fitch expects those demand specifications to vary significantly across the three key global EV markets – Europe, China and the US because EV battery performance demands will vary significantly based on a market’s EV charging network infrastructure (public and private), geography, consumer purchasing power and automotive culture.

These factors will inform the energy density (which is determined by the composition of active ingredients in battery materials and dictates EV range), thermal regulation (which controls battery temperature) and cost requirements in specific markets, Fitch says.

The environmental consciousness of a population and the structure of government EV purchase incentives (which sometimes prioritise certain models) will also influence the battery materials mix, the analyst says.

Over the longer term, Fitch expects the sustainability, traceability and recyclability of EV batteries to influence the demand outlook for key input materials such as lithium, nickel and graphite — particularly in Europe, the region which its commodities team expects to maintain its role as a regulatory leader within the li-ion battery recycling industry.

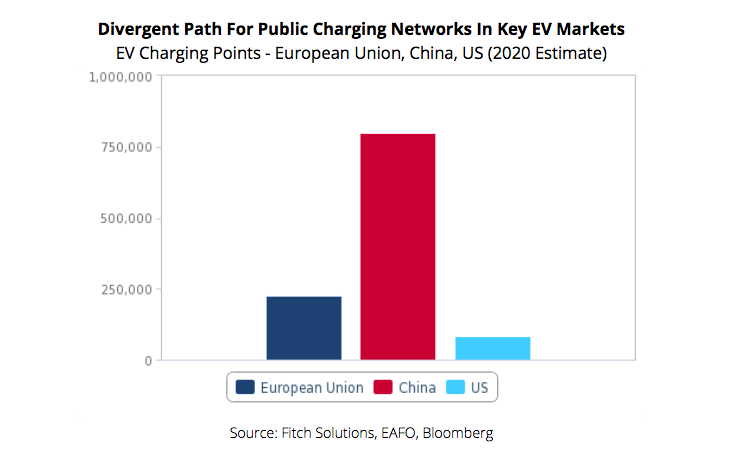

Endogenous factors such as a market’s size, population density and the residential status of its EV consumers will influence the extent to which the public and private EV charging network is expanded, Fitch says.

This will influence performance demands (and by extension the materials mix) for EV batteries, with consumers in densely populated markets like the Netherlands and China (which Fitch ranked as the 2nd and 11th mostly densely populated markets globally in 2020) less concerned with energy density because of their vast EV charging networks.

This affords consumers the luxury of utilizing EV batteries with a lower energy density and slower charging rates like the LFP (Lithium Iron Phosphate), as opposed to high-nickel variations of the NMC (Lithium Nickel Cobalt Manganese Oxide) cathode chemistry which have a far greater energy density, and by extension vehicle range.

Toward the latter stages of Fitch’s forecast period and beyond 2030, the analyst expects the cobalt-free NM battery chemistry to become increasingly more prevalent in the global EV market, as will all-solid-state batteries, which typically boast a higher energy density, faster-charging capacity and better thermal regulation than their liquid- electrolyte LiB counterparts.

Fitch expects automakers to hedge their bets on the battery chemistry mix, vertically integrating an extent of EV battery manufacturing where feasible while monitoring technological developments in battery chemistry and structure and procuring cells through long-term agreements with the relevant providers.

(Read the full report here)

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments