Mining copper tailings could answer supply deficits later this decade

Copper miners are taking another look at extracting value from their waste rock dumps, thanks to the record recent copper price rally and the application of new technology.

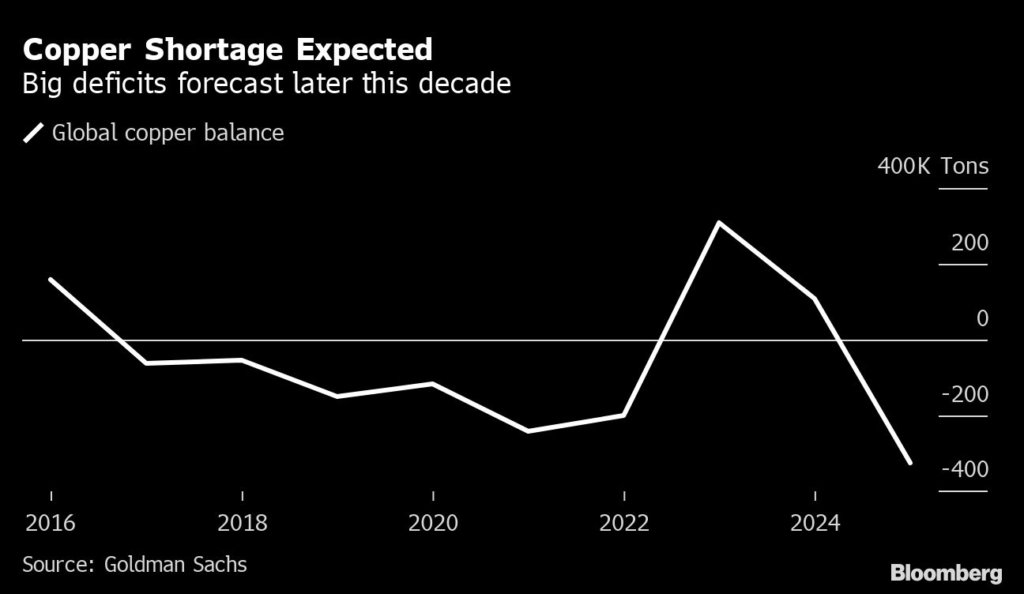

The copper price has recently traded at record levels on the back of investors piling into the red metal as global stimulus spurs demand and longer-term projections show supply won’t match the surge in consumption from the green-energy transition.

With the copper mine development cupboard remaining bare, both Trafigura Group, the world’s top copper trader, and Goldman Sachs Group say prices could hit $15,000 a ton in the coming years.

A new study released by CRU Group has found more than 43 million tonnes of copper is sitting idle in waste dumps at mines across the globe. The metal is considered too difficult to extract economically using conventional mining methods. That’s the equivalent of more than a decade’s worth of mine supply and worth $2.4 trillion at current prices, Bloomberg reports.

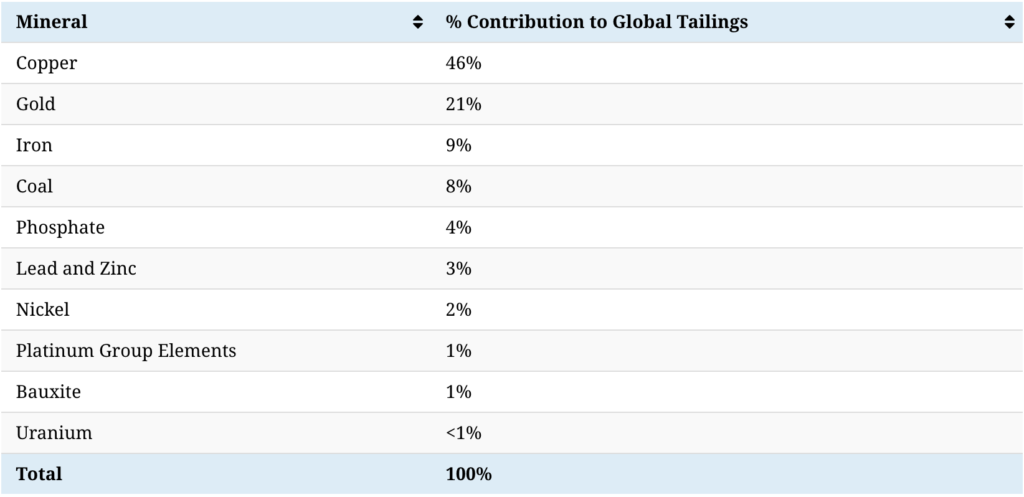

There is an estimated total of 217,330,652,000 m3 of tailings in storage globally, with copper accounting for about 46% of stored material globally.

But Boulder, Colorado-based start-up firm Jetti Resources aims to address the issue in light of massive forecast annual copper supply deficits expected to open from 2025 onwards.

Even Natural Resources Canada has estimated that there is about $10 billion in total metal value in Canadian gold mining waste alone. The Canadian Government’s Natural Resources Clean Growth Program has awarded Jetti with funding to further research and encourage projects utilizing its “more energy-efficient process to extract copper from regular- and lower-grade ores, as well as waste mining materials and tailings.”

Jetti has developed a catalyst that can liberate copper from low-grade chalcopyrite ores, known to have copper grades of well below 1%. The process works by disrupting the sulphur metal bond of the mineral.

Traditional leaching methods, which dissolve the metal to form a weak solution of copper sulphate, lead to a film forming over the copper in these ores, preventing it from being extracted.

“It’s a linchpin for unlocking a wasted resource base and converting it into reserves we can use,” Jetti CEO Mike Outwin told Bloomberg.

According to Jetti, the new process can be bolted on to existing plants and increase production by 20% to 100% depending on the type of operation.

Jetti’s new process can be bolted on to existing plants and increase production by 20% to 100%

The company installed its first commercial plant last year at a mine in Arizona run by Capstone Mining Corp (TSX: CS). Capstone says that by processing millions of tons of waste rock, it hopes to produce an additional 350 million lb. of copper, thought to be worth more than $1.6 billion at current prices, in the next two decades.

The technology could unlock the processing of millions of tons of copper that’s already been mined and it could help extend the life of existing mines while allowing new projects to process lower-quality ore from the start.

Jetti currently has a pipeline of 23 projects at various stages, including five pilots and three operations that it’s looking to transition to commercial status in the next year or so. By the middle of the decade, its plants could start having a material impact on global copper supply.

“We’re unlocking a colossal, stranded resource, but we’re not going to be doing it in an incredibly short period of time that swamps the industry with excessive production or at a dramatically lower cost than is currently done,” said Outwin.

(With files from Bloomberg and Visual Capitalist).

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments