Jetti Resources’ quest for copper mining’s holy grail

The mining industry knows all about the big copper conundrum.

The highly conductive red metal is actually the vital metal of the future that needs to be mined for the green energy era to come to fruition, but big, new deposits are rare.

New copper projects such as Cascabel in Ecuador and Pebble in Alaska and the Oyu Tolgoi expansion in Mongolia are often faced with community opposition, permitting delays and cost overruns.

Facing aging mines with lower grades, the industry is looking at how much more copper they can produce out of existing operations – Chile’s Codelco, for example, is planning massive upgrades of its aging mines.

Some mines halted or curtailed operations amid the coronavirus pandemic, and global economic growth projections were tossed aside.

New leaching technology

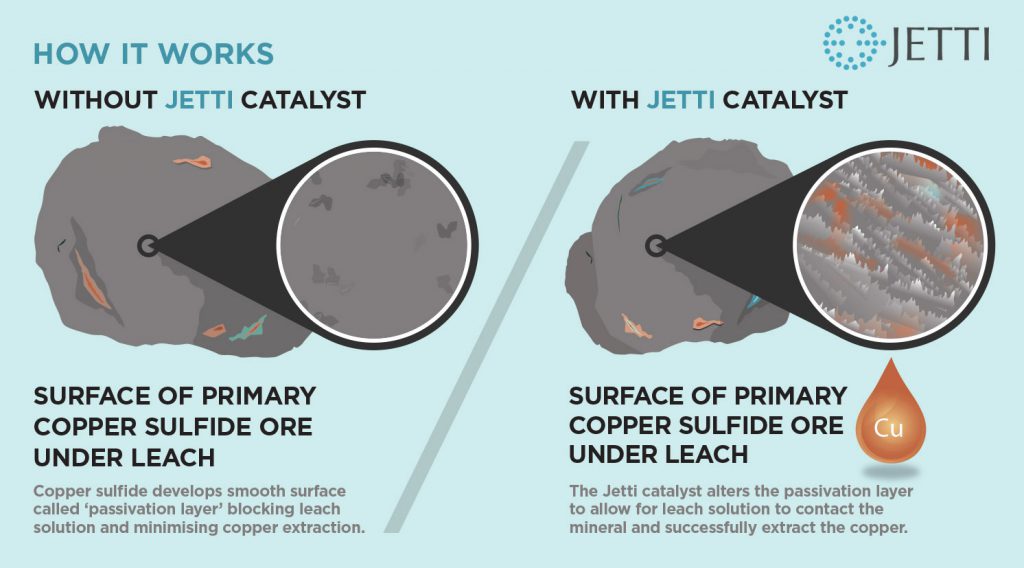

Jetti Resources is a start-up founded in 2014 that has introduced to the industry its eponymous technology, which it says makes it possible to extract copper from low-grade primary sulfides like chalcopyrite, the world’s most abundant copper mineral ore.

Headquartered in Colorado, with offices in Santiago and Vancouver, Jetti is a recipient of the Canadian Government’s Natural Resources Clean Growth Program funding to further research and encourage projects utilizing its “more energy-efficient process to extract copper from regular- and lower-grade ores, as well as waste mining materials and tailings.”

Its founder and CEO is 31-year-old venture capitalist Mike Outwin, who, in 2018, while based in Vancouver, was named one of BC Business magazine’s ’30 under 30′ business leaders.

“Its always been thought – if you can leach chalcopyrite – that’s the holy grail”

Mike Outwin, CEO, Jetti Resources

“For decades they’ve been trying to figure out how to utilize existing technologies and infrastructure to get copper out of that material,” Outwin told MINING.COM. “Its always been thought – if you can leach chalcopyrite – that’s the holy grail.”

On its quest for the holy grail of copper mining, Jetti Resources has attracted copper industry veterans Ken Pickering, former BHP Copper president, former BHP CEO Chip Goodyear, Trevor Reid, former Xstrata CFO, Jonathan Leslie, former CEO of Rio Tinto Copper and John Mackenzie, former CEO of Anglo American Copper.

“The major mining companies have long recognized that finding a way to increase copper recoveries when leaching low grade sulphide ores would generate a step change in industry economics,” Mackenzie said in an emailed statement. “Jetti has developed a technology that solves this conundrum in a cost-effective and environmentally responsible manner.”

According to Outwin, Jetti’s catalytic leaching technology addresses the key technical problem preventing recovery of potentially trillions of dollars of trapped resources.

Pinto Valley

Jetti technology was tested this year by Capstone Mining at its Pinto Valley mine in Arizona. During the first year of Capstone’s partnership with Jetti, cathode production per area irrigated has doubled, Capstone announced in July.

“Pinto Valley mine has successfully demonstrated positive economics from enhanced dump leach performance by partnering with Jetti Resources to apply their novel patented catalytic technology at Pinto Valley’s existing dump leach operation,” Capstone said.

“The technology that we’ve developed solves the problem [of] being able to leach chalcopyrite to get the copper out, that the industry currently assigned zero percent recovery to. Seventy percent of the world’s remaining copper resources are stuck in low-grade chalcopyrite,” Outwin said.

“As your ore grade goes down, you have dwindling accessibility to that process route. The ore has to have enough copper in it to justify traditional processing. We see huge opportunity because all of that low grade ore appearing in these mines that makes up large portions of the resource base is inaccessible to them, but with our technology it is accessible.”

Outwin said the Jetti technology is a “game changer” because miners generally assign zero percent recovery to the low grade chalcopyrite, which can make up a significant portion of their mines.

“What we’ve developed is a low cost catalyst that enhances the leaching – it’s the key that unlocks that layer and lets the copper out. We’re able to use existing technology and existing leaching infrastructure that [is in] place.”

For mines that have large unused chalcopyrite stockpiles, Outwin said Jetti’s technology enables the extraction of copper without having to interact with untouched deposits.

“There are sites out there…with capacity of 100,000 – 200,000 tonnes that are operating at 50% capacity right now. There’s a huge gap of copper production that’s not taking place because they are running out of material to run through that plant as a result of them approaching primary ores, which they can’t leach, up until now, with our technology,” Outwin said.

With this technology, just by deploying it at a site and using existing infrastructure, and going after the minerals they already have on-site – you’re effectively able to create a new mine.”

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments