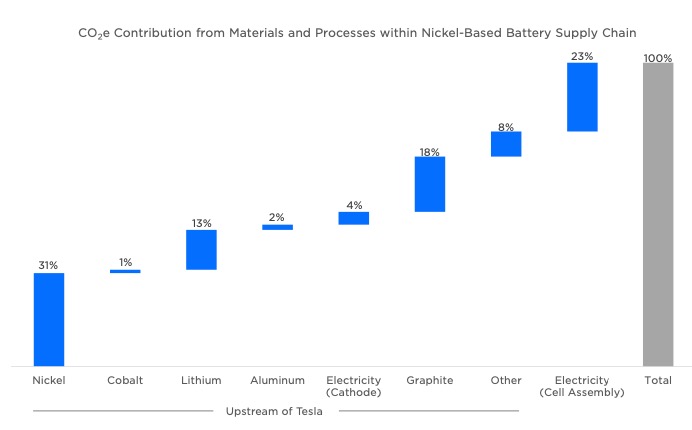

GRAPH: Nickel, graphite make up half Tesla’s battery emissions

Elon Musk has on more than one occasion expressed concern about nickel availability, but Tesla’s headaches when it comes to nickel don’t end there.

According to the carmaker’s so-called Impact Report released on Friday, nickel is by far the biggest problem in its supply chain for batteries when it comes to emissions, outpacing CO2 created by cathode manufacture and cell assembly combined.

Tesla said it commissioned London-based consulting and software firm Minviro “to identify hotspots with high global warming potential across eight specific processing routes from which we currently source cobalt, nickel and lithium.”

The report says Tesla sources over 95% of its lithium, 50% of its cobalt and 30% of its nickel directly and that “key drivers of CO2 in its global supply chain are the cathode and anode supply chains.”

Cobalt represents only 1%, while lithium, responsible for 13%, makes a more modest contribution than anode material graphite with the company pointing out that “chemical processing (refining / smelting) was a larger driver than mining.”

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments