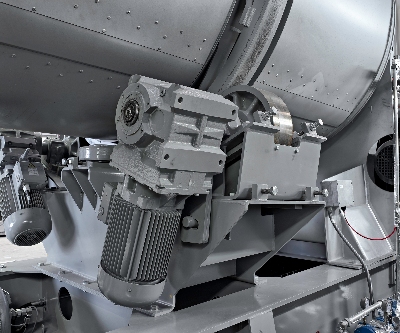

Are motors the tip of the iceberg when it comes to improving drive train efficiency?

Fuelled by the introduction of more stringent IE efficiency classes, manufacturers are chasing headline efficiency figures which could only have been dreamed of just 10 years ago. There’s no denying that this is a positive thing for industry, but is motor efficiency just the tip of the iceberg?