Platinum-gold alloy is the most wear-resistant metal in the world

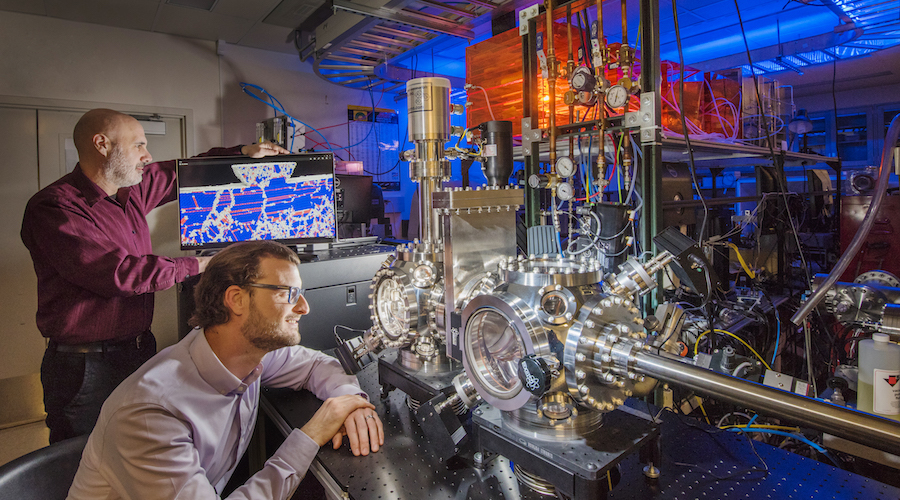

Researchers at the Sandia National Laboratories in New Mexico engineered a platinum-gold alloy believed to be the most wear-resistant metal in the world.

The metal is 100 times more durable than high-strength steel, making it the first alloy, or combination of metals, in the same class as diamond and sapphire.

The alloy is made of 90 per cent platinum with 10 per cent gold, which is nothing new. The innovation behind it is the handpicked metals, proportions and a fabrication process that the scientists employed based on simulations that calculated how individual atoms were affecting the large-scale properties of a material.

Such simulations allowed them to propose a new theory that says wear is related to how metals react to heat, not their hardness.

The scientists’ findings were published in a paper in Advanced Materials. In their article, they explain that the alloy will be particularly useful for the tech industry because in most electronic devices moving metal-to-metal contacts or pieces usually need to be coated with outer layers of gold or other precious metal alloys to prevent them from wearing down, corroding or getting deformed. Such alloys, however, don’t last for long as connections press and slide across each other day after day, year after year, sometimes millions of times.

Using an example to explain their achievement, the researchers said that the alloy is so durable that if car tires were fabricated with it, it’d be possible to skid around the Earth’s equator 500 times before wearing out the tread.

The new platinum-gold coating is so strong that only a single layer of atoms would be lost after a mile of skidding on the hypothetical tires. According to the lead researcher, Nic Argibay, this means that it could save the electronics industry more than $100 million a year in materials alone and make electronics of all sizes and across many industries more cost-effective, long-lasting and dependable.

In Argibay’s view, from aerospace systems and wind turbines to microelectronics for cell phones and radar systems could benefit from the new material, as it addresses current reliability limitations of metal microelectronic components.

More News

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments

Paul Davis

Ok, presuming this is reproducible, it means an increase in the amount of platinum used in electronics with a much larger decrease in the amount of gold. If the manufacturers can get by with a layer a few atoms thick, they’ll happily do so. This will be a net decrease in total PGM used on contacts, slides, switches and so forth. Also, they’ll last much longer. I’m not seeing this as promoting PGM use at all, save perhaps initially. And that’s if it is a practical process that can be used in a manufacturing environment at reasonable cost for consumer grade electronics.