It’s good news that Government has placed heavy legislation on asbestos removal and the disposal thereof — and although citizens are thankful, many companies have subsequently become overwhelmed by the myriad of requirements.

For many companies, the current legislation is not only a frustrating situation, but it’s becoming a very expensive one in which legislative procedures affect day to day operations — such procedures include contamination control, area security, removal, demolition and the arrangement of a recognised inspection authority to oversee the project and outcome.

Undoubtedly, this legislation is for the good of the public — and statistics from the World Health Organisation (WHO) have released its figures in which a staggering 125 million people are said to be exposed to asbestos in the workplace. In the same report, WHO stated that “107 000 people die every year from asbestos-related lung cancer and Asbestosis.”

Since asbestos must be removed according to health and safety standards, the solution would be to contact a company specialising in asbestos

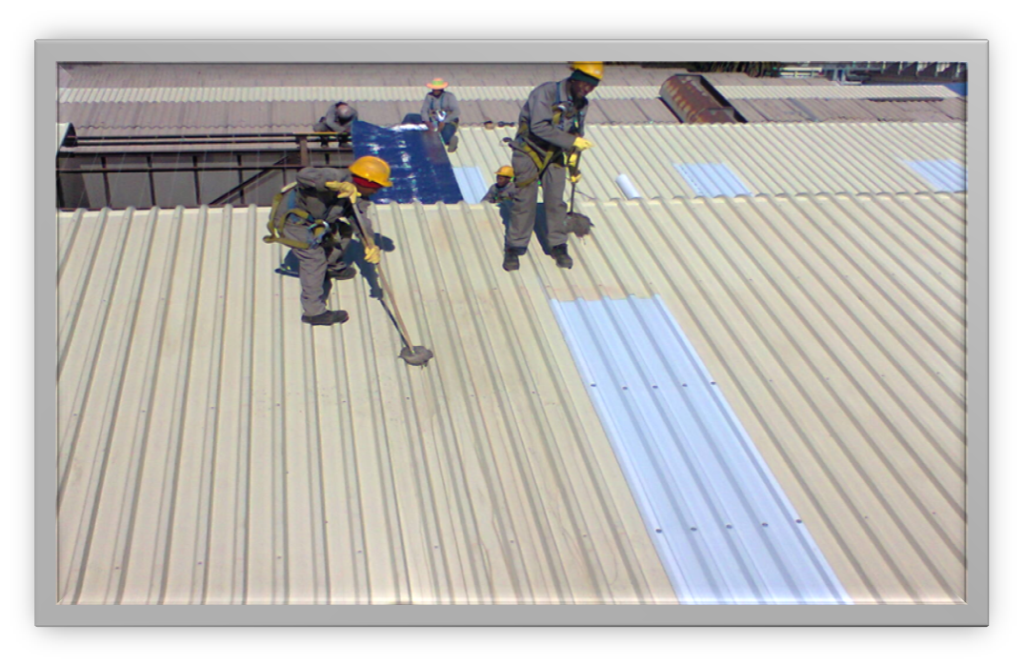

removal, but ensuring also the company is fully-compliant and that it can manage the project from start to end. Proof Engineering, a company in Wadeville (Gauteng) had this problem — and it was fortunate that they contacted R & D Contracting a specialist Asbestos removal company, for a total solution to their asbestos roofing at the site as the roof sheeting was replaced in conjunction the Asbestos remedial work.

The challenge, says Proof Engineering, was obtaining all the legal and OSH Act requirements as well as ensuring that working days were optimised to allow for Proof Engineering staff to work uninterrupted, and safely. R&D Contracting managed everything, including the arrangement of convenient project schedules and the final approval by registered AAIA inspector and DOL representatives.

Owing to R&D’s vast experience in this special field the use of a continual cranked IBR roof sheet was used along with Translucent sheeting to maximise allowable natural light and has since resulted in lighting previously required to luminate the factory to now being switched off during daylight operating hours resulting in a marked saving on electricity.

“Part of the remedial process meant that the installation of new Sisalation was done concurrently with the sheeting,” says R&D Contracting foreman, Sibusisu Dludlu, adding that, “therefore no additional delay to the project was incurred.”

A safety net system with a shade net lining was rigged with each new section facilitating Proof Engineering operations to proceed uninterrupted with the added benefit of safety for both R&D Contracting staff working at height as well as Staff and equipment below the area being worked.

Experts strongly urge that the complex nature of asbestos removal be left in capable, competent hands like R&D Contracting who is being recognised for its innovative and professional outlook on projects, further supporting its ethos of “Maintaining through innovation”

www.r-d.co.za