Crusher Wear Solutions: Enhancing Safety, Reliability, and Performance

Discover how our high-performance wear products, services, and solutions – expertly designed for primary, secondary, and tertiary crushing applications – can enhance your processes.

Enhancing Safety and Reliability with Crusher Wear Parts and Safety Tooling

and innovative designs engineered to meet the specific demands of primary, secondary, and tertiary crushing applications. Our optimized solutions deliver superior performance, durability, and reliability, making us your trusted partner for all of your crusher wear solution needs.

Engineered for quick and seamless replacement, our crusher products are designed to minimize and keep operations running smoothly. With fast and precise liner change-outs, we help our customers maintain high productivity while reducing operational disruptions.

At ME Elecmetal, we focus on addressing customer challenges with integral solutions that deliver real value. By prioritizing safety, durability, and ease of use, our products seamlessly integrate with your on-site equipment. This commitment not only boosts performance but also extends the lifespan of your machinery, maximizing efficiency and reliability.

Additionally, our extensive range of Crusher Safety Tooling is designed to enhance operational efficiency, enabling safer, faster, and more effective task execution. Trust ME Elecmetal’s expertise to deliver solutions tailored to your operational needs, supporting your success at every stage.

Innovation Driven by Experience and Technical Knowledge

Optimization Tools and Services

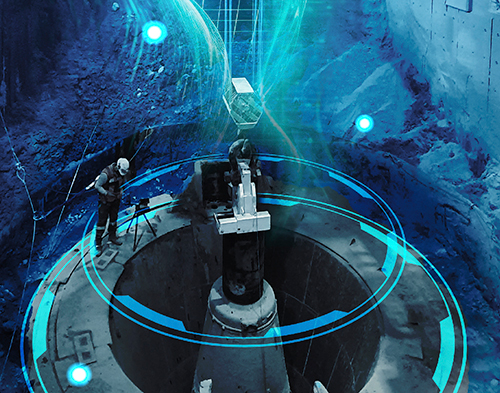

ME Elecmetal drives industry innovation by leveraging advanced digital tools to optimize crushing operations. Our approach goes beyond traditional methods, using large-scale data analysis to develop customized solutions that tackle our clients’ unique challenges. By integrating cutting-edge technology, we enhance operational efficiency, boost productivity, and deliver measurable value.

Our suite of optimization tools is designed to offer insights and wear monitoring, ensuring every decision is data-driven and focused on maximizing performance. However, our commitment goes beyond just delivering innovative tools – we work closely with our clients to provide expert guidance, continuous support, and tailored solutions that drive long-term success.

We provide unparalleled technical support and training, equipping our clients and their teams with the knowledge and skills needed for optimal performance. Our services include 3D laser scanning, ™ and QuickScan™ Crushing for precise wear analysis, liner change-out optimization to minimize downtime, and continuous improvement programs that drive long-term operational excellence.

The ME Elecmetal Difference

Extended Service Life

At ME Elecmetal, we utilize premium wear materials to enhance the longevity of our products, ensuring components operate efficiently for extended periods. This reduces the frequency of replacements, leading to lower maintenance costs and a more sustainable use of resources. By prioritizing durability, we help our customers improve operational efficiency while minimizing downtime and environmental impact.

Reduced Maintenance

With the extended service life of our products, the need for frequent preventive maintenance is significantly reduced. Our durable solutions minimize wear and tear, allowing for longer intervals between maintenance cycles – ultimately enhancing productivity and lowering operational costs.

Efficient Replacement Solutions

Our crusher products are engineered for quick and seamless replacement, minimizing downtime and ensuring continuous operations. By designing components that can be replaced with speed and precision, we help our customers maintain high productivity levels while reducing operational interruptions.

Expertise in Chamber Design Optimization and Liner Change-Out Forecasting

Our expertise in chamber design optimization and liner change-out forecasting allows us to anticipate potential component failures or wear patterns with precision. By leveraging advanced technology and data analysis, we can notify our customers well in advance, ensuring timely changes that help prevent unscheduled downtime. This proactive approach enhances operational efficiency, minimizes disruptions, and maximizes the lifespan of key equipment components.

Fully Integrated Technology

ME FIT®: Fully Integrated Technology

The ME FIT® Program harnesses over a century of expertise in the mining, aggregate, and recycling industries through our ME FIT Crushing and ME FIT Grinding optimization programs. Each program is custom-tailored to address the unique challenges of individual operations, aligning with our customers’ production strategies and productivity goals.

Our integrated solutions, provided through the ME FIT® Programs, deliver substantial value to our customers’ processes. Engineered for significant productivity enhancements, these solutions lead to more efficient and effective operations. At ME Elecmetal, our commitment is to elevate the performance and success of our clients.

ME FIT Crushing

The ME FIT Crushing Program is focused on optimizing efficiency in the initial stage of ore comminution. With ME Elecmetal’s in-depth expertise in the complexities of crushing operations, we quickly address the unique challenges and needs of our customers. This agility allows us to deliver solutions that enhance key performance indicators (KPIs) such as tons per hour, safety management, equipment availability, maintainability, and risk prevention.

We evaluate the value of our solutions not in isolation but by their comprehensive impact on our customers’ entire processes. By aligning with their priorities and operational strategies, ME Elecmetal positions itself as a strategic partner in crushing. Our commitment is to drive success collaboratively, ensuring our solutions play a significant role in achieving our customers’ broader goals.

VAP Philosophy

ME Elecmetal’s Value Added Philosophy is more than just a work methodology; it’s a strategic approach to overcoming complex technical challenges. This philosophy, which has long been a cornerstone of our operations, focuses on delivering holistic solutions that enhance the value of mining processes, building long-term relationships grounded in trust.

ME Elecmetal offers innovative products, services, and solutions that bring tangible value to our clients’ operations. Our commitment to improving efficiency, sustainability, and excellence drives our continuous pursuit of operational success in every partnership.

At ME Elecmetal, we are dedicated to elevating your crushing operations by providing the tools and expertise needed to optimize processes and boost productivity. Discover how our high-performance wear products, services, and solutions can enhance your processes!

Contact Us Today!

Learn more about our ME FIT Programs and other solutions by visiting www.me-elecmetal.com or contacting us at 480-730-7500.

SAVE THE DATE!

Mark your calendars for March 25-27, 2025, and join us at the America’s Center in St. Louis, Missouri for AGG1 2025! Meet the ME Elecmetal team at Booth 642 and discover the latest innovations and solutions for the aggregates industry.

Visit our website for more info: https://usa.me-elecmetal.com/en-us/events/agg1-academy-expo-2025/.

We can’t wait to see you there!

About ME Elecmetal

ME Elecmetal is a leading global supplier and strategic partner in the mining industry, renowned for its commitment to innovation and technology. Dedicated to delivering cutting-edge, sustainable solutions, ME Elecmetal consistently exceeds customer expectations worldwide.

With a comprehensive range of products and services – including grinding media, mill liners, crusher liners, and large specialty castings – ME Elecmetal is the preferred partner for crusher operators and mineral processors looking to optimize their operations.

The company operates nine state-of-the-art metallurgical plants strategically located across Chile, the USA, Peru, China, South Africa, and Zambia. With a robust manufacturing capacity exceeding 134,000 tons for foundry products and 600,000 tons for grinding media, the company continues to meet the growing demands of the mining industry.

ME Elecmetal’s commercial presence extends to over 40 countries, solidifying ME Elecmetal’s position as a global leader in delivering innovative solutions to the mining sector.

Learn more about ME Elecmetal’s global footprint and commitment to excellence in mining solutions at www.me-elecmetal.com.

Comments