Coal country to carbon innovation: Wyoming rare earths discovery could be a game changer for US

While many majors are walking away from the coal business to improve ESG metrics and appease investors, some savvy miners are looking at ways to advance clean energy projects on current and former coal mine sites.

Rare earths, essential elements to realizing an electrified economy, are being discovered latent in some old coal mines – which are seen as environmental legacy liabilities all over North America.

Ramaco Resources, (NASDAQ: METC) a Kentucky-headquartered pure play metallurgic coal miner with operations in West Virginia and Pennsylvania, has this month discovered new potential magnetic rare earth elements (REEs) at its Brook mine in Wyoming, the state which produces about 47% of the country’s coal and where virtually all coal is thermal.

Ramaco’s subsidiary, Ramaco Carbon, is partnering with laboratories, researchers, and manufacturers and is privately investing to create an ecosystem of carbon tech innovation — building what it calls Carbon Valley in Wyoming.

The discovery was made in a partnership with a federal research team from the Department of Energy’s National Energy Technology Laboratory (NETL), with validation from independent analysts at mining consultancy Weir International — and could pose a potential solution to growing demand that has eluded the US.

There is only one active mine for magnetic REEs in the United States, Mountain Pass in California, which is part owned by Chinese interests and exports its materials to China to be refined. Meanwhile, in recent years, China has come to control 91% of refining activity, 87% of oxide separation and 94% of magnet production, the Wall Street Journal reported.

Undersupply of magnet rare earths is projected to hit 60,000 tonnes by 2030. Adamas Intelligence predicts that from 2023 through 2040 global demand for NdFeB magnets will increase at a compound annual growth rate of 7.5%, bolstered by double-digit growth from electric vehicle and wind power sectors.

‘A new carbon age’

The Biden administration has already begun to look at coal ash, coal waste, and acid mine drainage as feedstock for rare earths. The United States government announced in April it has set aside $450 million to advance clean energy projects on current and former coal mine sites, giving special attention to those that can provide new economic opportunities for coal communities.

Following eighteen months of core drilling and independent chemical analysis, NETL researchers and Ramaco now believe that the Brook mine property contains what could be the largest unconventional deposit of REEs discovered in the United States.

The mine’s reserves are also low in any form of radioactive materials such as thorium, and the deposits are found at reasonably shallow depths — mainly in softer clay and related strata above and below coal seams, which makes rare earths easier and more economic to extract than from hard rock deposits.

Most rare earth is found in conventional hard mineral deposits such as cobalt, uranium, or lithium.

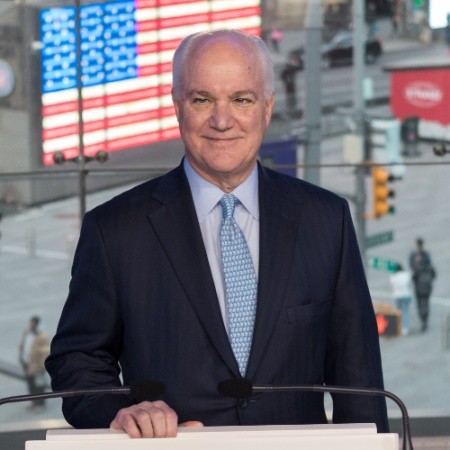

“Unconventional deposits are found in softer substances like clays — and clay- like stratus, which is what we’ve got. About 80% of the value of Chinese rare earth is found in ionic clay deposits — it is much less expensive to process because it’s a softer processing technique and it’s also less environmentally intrusive,” Ramaco founder and CEO Randy Atkins said in an interview with MINING.com.

The mine ranks among the highest relative concentrations yet discovered of magnetic rare earths (MREE) such as heavy REEs terbium and dysprosium, as well as lighter REEs such neodymium and praseodymium. Initial estimates are that about 28% of deposit concentrations may be in the form of MREEs.

These observations were from an assessment of 4,500 acres, less than one third of the total 15,800-acre area of the Brook mine.

Ramaco Resources acquired the Brook mine, near the town of Sheridan at the foothills of the Bighorn Mountains in 2011. It was in operations from 1890s to about 1930. Atkins has proposed a fundamentally new, environmentally positive use for carbon derived from its coal. Atkins is a past chairman of the National Coal Council, which is an arm of the Department of Energy.

“Our approach is to use the commodity as a low-cost carbon feedstock to make high-value advanced carbon products and materials that we call “coal to products.” We have coined the phrase “carbon ore” to refer to coal used in this manner,” Atkins said in a testimony to the Senate Committee on Energy and Natural Resources in 2021, which he called “The New Carbon Age”.

Ramaco bought Brook mine from Pittston Coal, which was owned by Brinks, the armored car company.

“Brinks was trying to get out of the coal business, so we rather opportunistically bought this reserve in 2011 — it was the last reserve they’d had. They owned it since 1912,” Atkins told MINING.com.

“Until the catalytic converter was made to convert petroleum into refined products, all the chemistry came from coal,” Atkins said.

“So we’re going back to that and using obviously a centuries worth of new technologies and advances in material and manufacturing to come up with a whole different way to look at it.”

“We bought it with the notion that we would develop it and see what we could make of it,” Atkins said. “I began to explore alternative uses of coal. We had started our permit mine planning and it became apparent to me that even though we were going to continue on the trajectory of planning and permitting the mine that the idea of opening a brand new thermal coal mine was a difficult proposition to justify deploying a lot of capital toward.”

“One of the areas that we highlighted was that critical minerals was a possibility of being derived from coal because there had been some work done actually in China and really not much had been done in the US,” he said.

Ramaco has already completed the permitting process for Brook mine, which took eight years — it is fully permitted to begin mining, and the company is aiming to begin in Q4 this year.

With the area already permitted, mine development could be initiated later this year, after the full year of water monitoring ends at the third quarter. More drilling and testing will continue to determine the ultimate size and character of the REE opportunity over the entire area, including the property that has not yet been assessed.

Ramaco entered into a cooperative research and development agreement with a National Energy Technology Lab trying to create an assessment of where rare earths might be found in the US —including everything from lignite to acid mine drainage to coal deposits in every basin, including uranium and cobalt and any other hard mineral they could be found in.

“They were frankly shocked that they had found concentrations and mostly concentrations in heavy rare earths that were higher than they’d found any place else in the world except outside of Western China and certainly higher than anything they’ve found in the US,” Atkins said.

In the last two years Ramaco focussed on more intense drilling and chemical assessment.

“We put down about 100 drill holes to try to define the nature of the of the deposit,” Atkins said. “We finalized our exploration report and it determined that we have what’s really the largest unconventional RE deposit in the US from their opinion and that it clearly also one of the ones that has the highest concentration of magnetic rare earths.”

Processing partnerships

With a clay deposit like at the Brook mine, physical separation and a light flotation process with a mild solvent separates the rare earths.

“We’re doing more testing to determine if these are ionic in character and if they are, then that makes it even easier to process, because then you just do an ion substitution, and the rare earths fall off — that’s why it’s kind of a big deal to have an ionic deposit because you don’t have to go through either a very expensive processing technique or ship it over to China.”

“As a result of this, we can instead probably look at the coal almost as a as a by-product of mining for the rare earths because the value is all going be of course in the rare earths and not in coal.”

Ramaco is working with the University of North Dakota, which has been doing processing on lignite and with the University of Kentucky, where testing on various terms of types of rare earth conversions from coal is being done to determine best practices.

“I’ve kind of been the only one waving the flag for the third leg of the stool, which is to use coal for alternative purposes, and I think it has a great future in a more technologic use than what people have looked at before,” Atkins said.

“We have financial capability to develop this without having to go get government loans. It’s nice to have Washington on your side and by virtue of doing this alongside a technology lab we have gotten a lot of good reality checks along the way because they have testing and assessment capabilities that nobody else has got — and we won’t be dependent upon China if we get this mine in.”

{{ commodity.name }}

{{ post.title }}

{{ post.date }}

Comments