Lithium-ion batteries are at the center of the clean energy transition as the key technology powering electric vehicles (EVs) and energy storage systems.

However, there are many types of lithium-ion batteries, each with pros and cons.

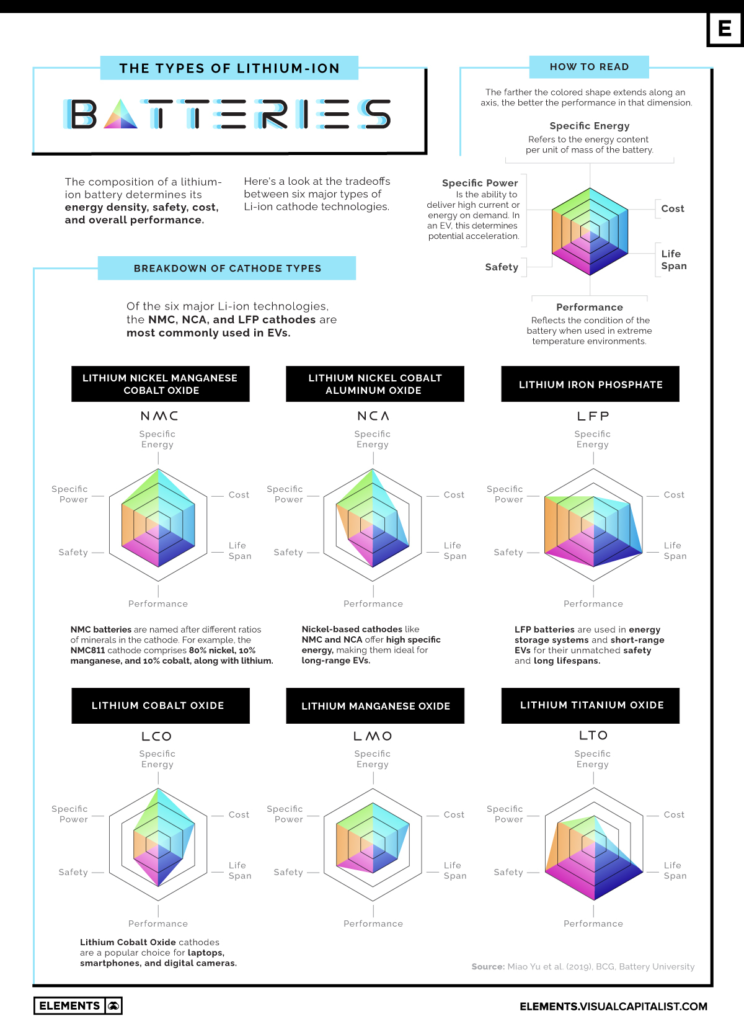

The above infographic shows the tradeoffs between the six major lithium-ion cathode technologies based on research by Miao et al. and Battery University. This is the first of two infographics in our Battery Technology Series.

Each of the six different types of lithium-ion batteries has a different chemical composition.

The anodes of most lithium-ion batteries are made from graphite. Typically, the mineral composition of the cathode is what changes, making the difference between battery chemistries.

The cathode material typically contains lithium along with other minerals including nickel, manganese, cobalt, or iron. This composition ultimately determines the battery’s capacity, power, performance, cost, safety, and lifespan.

With that in mind, let’s take a look at the six major lithium-ion cathode technologies.

NMC cathodes typically contain large proportions of nickel, which increases the battery’s energy density and allows for longer ranges in EVs. However, high nickel content can make the battery unstable, which is why manganese and cobalt are used to improve thermal stability and safety. Several NMC combinations have seen commercial success, including NMC811 (composed of 80% nickel, 10% manganese, and 10% cobalt), NMC532, and NMC622.

NCA batteries share nickel-based advantages with NMC, including high energy density and specific power. Instead of manganese, NCA uses aluminum to increase stability. However, NCA cathodes are relatively less safe than other Li-ion technologies, more expensive, and typically only used in high-performance EV models.

Due to their use of iron and phosphate instead of nickel and cobalt, LFP batteries are cheaper to make than nickel-based variants. However, they offer lesser specific energy and are more suitable for standard- or short-range EVs. Additionally, LFP is considered one of the safest chemistries and has a long lifespan, enabling its use in energy storage systems.

Although LCO batteries are highly energy-dense, their drawbacks include a relatively short lifespan, low thermal stability, and limited specific power. Therefore, these batteries are a popular choice for low-load applications like smartphones and laptops, where they can deliver relatively smaller amounts of power for long durations.

Also known as manganese spinel batteries, LMO batteries offer enhanced safety and fast charging and discharging capabilities. In EVs, LMO cathode material is often blended with NMC, where the LMO part provides a high current upon acceleration, and NMC enables longer driving ranges.

Unlike the other chemistries above, where the cathode composition makes the difference, LTO batteries use a unique anode surface made of lithium and titanium oxides. These batteries exhibit excellent safety and performance under extreme temperatures but have low capacity and are relatively expensive, limiting their use at scale.

Now that we know about the six main types of lithium-ion batteries, which of these dominate the EV market, and how will that change in the future?

To find out, stay tuned for Part 2 of the Battery Technology Series, where we’ll look at the top EV battery chemistries by forecasted market share from 2021 through 2026.

(This article first appeared in the Visual Capitalist Elements)

Comments