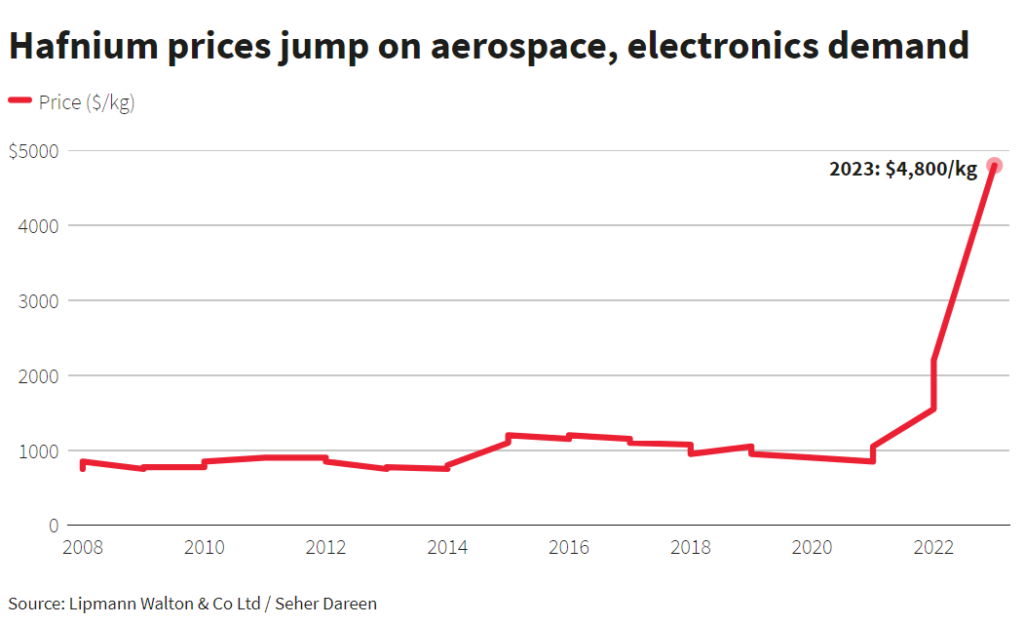

Shortages created by robust demand from the aerospace and electronic industries as growth accelerated after the lifting of Covid restrictions have fueled a 400% rise in hafnium prices, taking them to record highs.

Prices of the metal, valued for its anti-corrosive properties and used to make control rods for nuclear reactors, have shot up to $4,500-$5,000 a kg from $1,200-$1,400 a kg a year ago, traders said.

“We are seeing the price of hafnium rise as the market is structurally supply constrained,” Rowena Smith, chief executive at Australian Strategic Materials, said.

Hafnium is mostly used as an additive in nickel-based superalloys for industrial and aero gas turbine engines.

“With the resurgence of aircraft production and growing demand for hafnium tetrachloride coatings from semiconductor manufacturers for the next generation of nanochips, the hafnium market is now experiencing a period of significant imbalance between supply and demand,” Smith said.

Hafnium is a byproduct of the purifying of zirconium for use in nuclear plants.

Roughly 50 tonnes of zirconium is needed for each tonne of hafnium. Traders’ estimates of global hafnium supplies range between 80 and 90 tonnes annually.

Lipmann Walton’s Michael Husakiewicz said shortages of hafnium were between five and 10 tonnes last year. “The semiconductor and electronic industries held a relatively small share of the hafnium market, several percent in 2017-2018, now it’s probably double that number and growing.”

According to the US Geological Survey, Australia, Senegal and South Africa exported zirconium concentrates last year, while leading importers were China, India and Spain.

A small but significant 3% of hafnium is produced in Russia, but in the absence of an export licence from the Russian government for the dual-use material, it is out of reach for the larger market.

“Even though the quantities were small – a couple of tonnes per year – (Russia’s) absence from the market has increased hafnium deficit,” Husakiewicz said.

One trader said hafnium supplies from China could ease the shortages, but that exports from the country appear to have stalled.

China is likely to register the highest compound annual growth rate for hafnium use over 2023-2028, according to India-based Mordor Intelligence, given that the country expects to build six to eight nuclear reactors a year between 2020 and 2025.

(By Seher Dareen; Editing by Pratima Desai and Barbara Lewis)

Comments