Britishvolt, the UK startup which struggled to raise funds for an major electric vehicle battery factory in northern England, filed for administration on Tuesday in a blow to the country’s hopes of building a home-grown battery industry.

Britishvolt’s failure marks a step back for Britain’s car sector as industry officials and experts see domestic EV battery plants as essential to keep UK car production from shifting to mainland Europe.

Britishvolt had been in talks with potential buyers after securing a short-term funding lifeline in November to help keep it afloat.

Competing bids of around £30 million ($36.8 million) from three early investors versus Indonesia-linked investment fund DeaLab Group were rejected by Britishvolt’s creditors.

“We remained hopeful that Britishvolt would find a suitable investor and are disappointed to hear that this has not been possible,” Britain’s business department said in a statement.

The department said it would continue to work with local authorities and potential investors to secure the best outcome for the site.

A team from accounting firm Ernst & Young’s restructuring arm EY-Parthenon have been appointed as administrators.

The administrators said Britishvolt had gone into administration “due to insufficient equity investment” for its ongoing research and development of its sites”.

A majority of Britishvolt’s 300 staff were told on Tuesday they were being made redundant with immediate effect, two sources familiar with the matter said.

“The news that Britishvolt is filing for administration is deeply disappointing, and a blow to the UK’s transition to cleaner, cheaper transport,” said Ben Nelmes, chief executive of British transport research firm New Automotive.

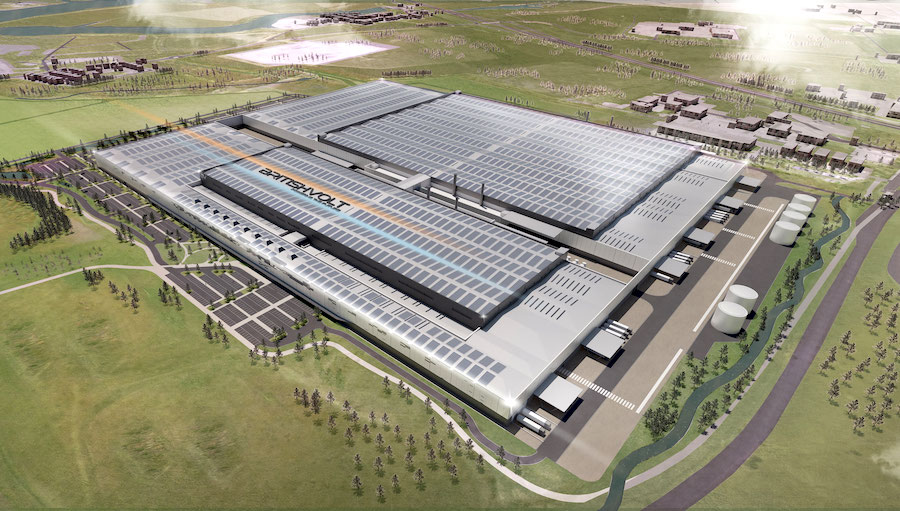

Britishvolt had previously outlined ambitious plans for a 3.8 billion pound ($4.65 billion) 38 gigawatt-hour plant in England’s industrial north to build electric vehicle batteries.

The planned plant site at Blyth is regarded as Britain’s best “shovel-ready” location to make EV batteries at scale, with the land already acquired and planning permission in place.

The British government under former prime minister Boris Johnson had touted Britishvolt’s project as a major milestone toward building an EV industry as the country heads toward a ban on combustion engine cars in 2030.

The government had committed 100 million pounds to Britishvolt’s plant, to be paid out once construction began. On Tuesday it confirmed no grant had been paid out because the private funding milestones had not been met.

“Back in July Boris Johnson when he was the prime minister told me that the cheque was in the post to Britishvolt,” opposition Labour politician Ian Lavery said in a statement. “But the reality is they have never received a penny from the government.”

Britishvolt had only raised around 200 million pounds by summer 2022 and had pushed back its production timeline.

Rising interest rates and the risk of recession have made fundraising much harder for many startups – especially those seeking huge sums for vast projects like an EV battery plant.

To comply with trade requirements with the European Union, a large part of an EV by value must be built in Britain to avoid tariffs.

Britishvolt had received backing from mining giant Glencore, which kicked off a funding round for the startup last February.

Industry experts estimate Britain needs four to six large battery plants to sustain a healthy car industry.

It currently has one small 1.9 gigawatt-hour (GWh) Nissan plant in Sunderland, northeast England. The Japanese carmaker is building a second 9 GWh plant at the same location with Chinese partner Envision AESC, which could expand to 25 GWh.

($1 = 0.8168 pounds)

(By Nick Carey, Michael Holden and Sachin Ravikumar; Editing by Kylie MacLellan, Louise Heavens, Jane Merriman and Emelia Sithole-Matarise)

Comments