Japan’s Sumitomo Metal Mining Co Ltd aims to increase its capacity to produce cathode battery materials and to broaden its range of products to meet rising demand from the electric vehicle (EV) sector, its president said on Thursday.

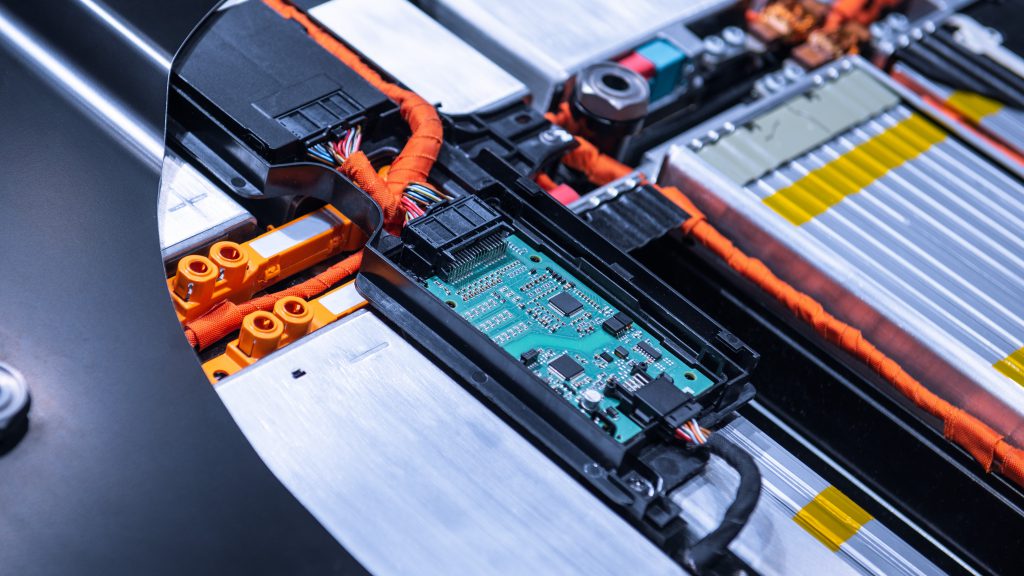

The company, which supplies the nickel-cobalt-aluminum (NCA) cathode materials for the Panasonic lithium-ion batteries used in Tesla EVs, is building a plant in Niihama, western Japan, to boost its monthly cathode production by 2,000 tonnes by March 2026 from 5,000 tonnes now.

It is considering further expansions with a view to raising its monthly output capacity to 15,000 tonnes by March 2031.

“We are considering making investments at the optimal timing and location, considering various changes in regulations worldwide including the United States,” President Akira Nozaki told an analysts’ meeting.

The Japanese company is also considering expanding its products to include lithium iron phosphate (LFP) following its acquisition of Sumitomo Osaka Cement’s LFP business earlier this year.

NCA cathodes and other nickel-rich cathodes can store more energy, but use costly materials such as nickel and cobalt. LFP cathodes typically hold less energy, but are safer and tend to be less expensive because they use materials that are more abundant.

China adopted the technology early and makes 95% of the world’s LFP batteries.

Sumitomo Metal set up its LFP project department in October to accelerate development of the technology in preparation for future market changes.

SMM, Japan’s biggest smelter of nickel, is also seeking a nickel mine project after abandoning a long-running feasibility study on an Indonesian nickel processing plant project in Pomalaa.

“We are accelerating the exploration of projects at various stages, mainly in the Pacific Rim region,” Nozaki said.

(By Yuka Obayashi; Editing by Barbara Lewis)

Comments