Metals are the backbone of clean energy infrastructure and technologies, but the mining and processing of energy transition metals also generates significant carbon emissions.

From the lithium and cobalt needed for electric vehicle batteries to the rare earth metals which power wind turbines, procuring all of these metals comes at a cost to the environment.

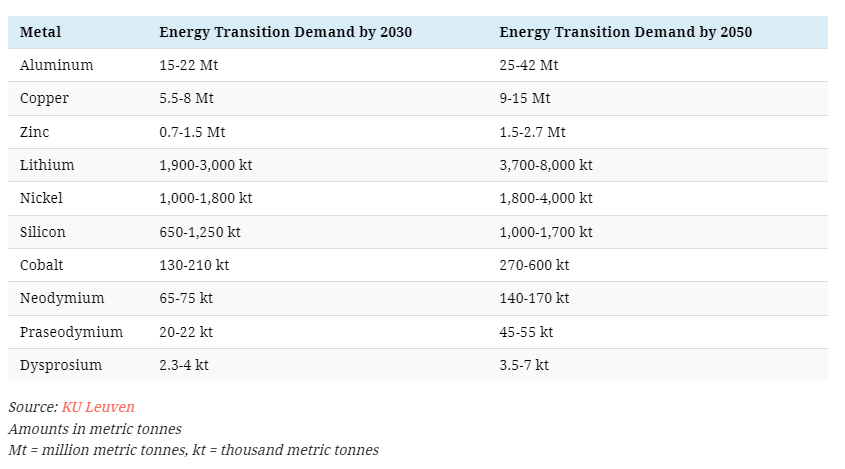

This graphic uses data from a KU Leuven report to visualize the carbon emissions from the mining and processing of various energy transition metals.

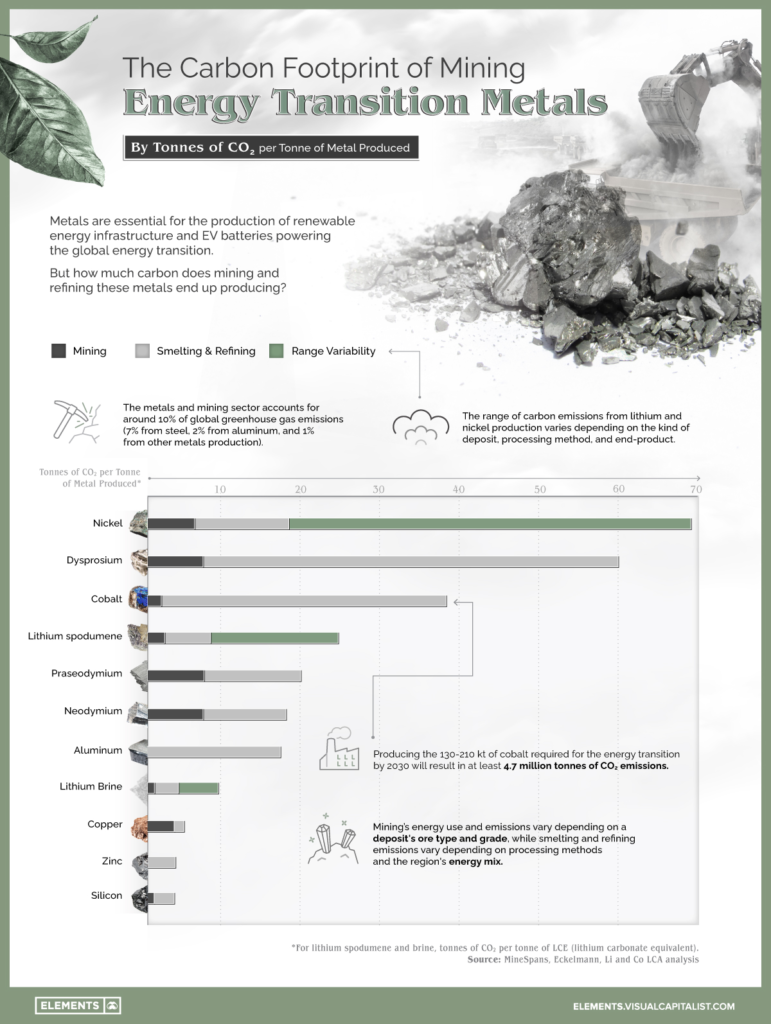

Metals mining and processing are highly energy-intensive operations, with the sector accounting for approximately 10% of global greenhouse gas emissions. While steel production makes up a large part of mining and metal emissions on the global scale (7%), other metals also generate millions of tonnes of carbon dioxide equivalent each year.

Nickel, dysprosium, and cobalt are the three metals which generate the most CO2, with nickel having a high variability depending on the deposit type and end product.

Dysprosium is an essential rare earth metal that is used in neodymium-based magnets found in wind turbines and electric vehicles. Nickel is primarily used in the production of stainless steel, but it is also essential alongside cobalt for the production of nickel-cobalt-aluminum and nickel-manganese=cobalt cathodes for EV batteries.

As a result, the demand for these metals is expected to increase significantly over the next three decades:

While electric vehicles decarbonize automotive emissions, producing the low estimates of the nickel and cobalt needed for the global energy transition (one million tonnes of nickel and 130,000 tonnes of cobalt) would result in almost 25 million tonnes of CO2 emissions.

Mining is a highly energy and carbon-intensive process due to the large amounts of heavy machinery and equipment required to extract ore from the ground. However, it’s the processing stages of smelting and refining that typically generate the most carbon emissions.

As seen with lithium and nickel on the chart, these emissions can vary greatly depending on the deposit type and processing methods used to make different end products.

Similarly, lithium production emissions also vary depending on their deposit type and end product.

While there’s plenty of variability, even the lower end of the ranges for nickel and lithium production results in large amounts of carbon emissions.

Along with carbon emissions from mining and processing operations, these projects have additional tolls on the environment.

Open pit mines dig up vast areas of land spanning multiple kilometers, releasing large amounts of dust and asbestos-like minerals. Along with this, mineral processing operations consume large amounts of water, and resulting mine tailings pose various risks if not stored and disposed of properly.

Simply put, the energy transition will require large amounts of land, energy, and water for the carbon-intensive process of metals mining and refining.

(This article first appeared in the Visual Capitalist Elements)

Comments