Steel alloys are mainly used in the steel industry – but battery and energy storage applications mean they will also play an increasingly important role in the energy transition, says Wood Mackenzie, a Verisk business (Nasdaq:VRSK).

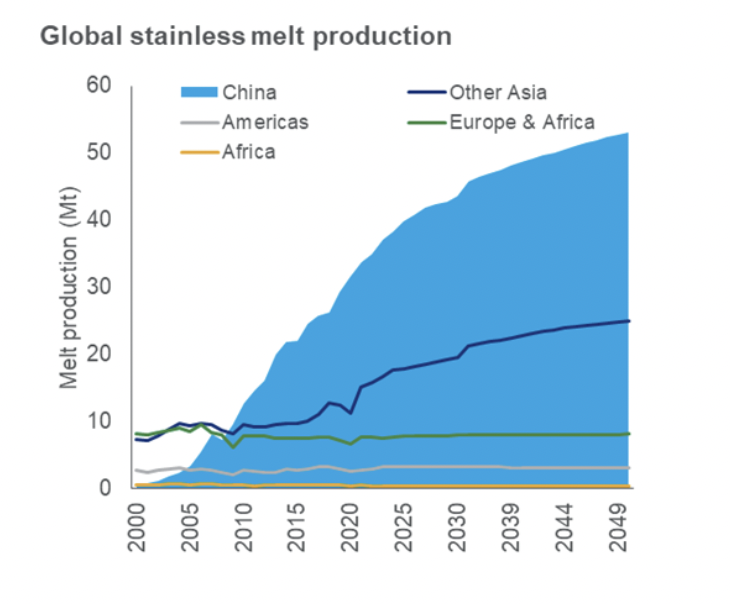

Global stainless steel melt production is expected to be about 62 million tonnes (Mt) in 2022, rising to 90 Mt by 2050. China currently accounts for 60% of production and is home to six of the world’s top ten producing companies. It is also expected to be the main driver of future growth, supported by Indonesia and India.

In contrast, production in Europe, the Americas and Africa will stay almost flat over the next three decades.

Stainless steel accounts for around 80% of world chromium consumption, 65-70% of nickel, and 20-25% of molybdenum. All stainless steel contains chromium, while use of nickel depends on the grade.

In the mature industries of Europe, the US and Japan, more than 50% of the input material is scrap, which contains nickel and chromium priced at a discount to the pure metal. As a younger industry, China has historically had less access to scrap but will be able to use more in future. This will flatten demand for chromium, nickel, and molybdenum over the long term.

Dale Hazelton, Head of Steel Alloys and Nickel Markets, said: “We expect demand for stainless steel to grow by 4% this year to 55 Mt. Home appliances have contributed strongly to recent demand, while the auto industry is recovering but still suffering from supply chain issues. Meanwhile, construction should get a boost from this year’s focus on infrastructure investment in China.”

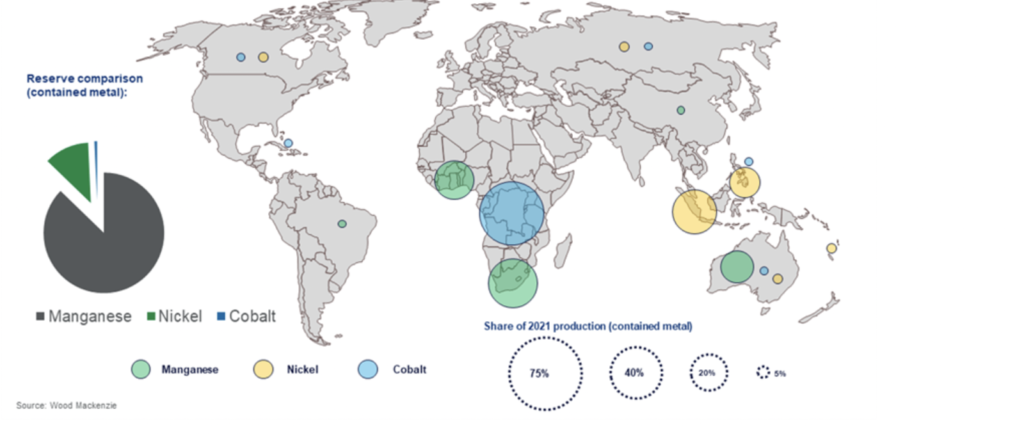

The bulk alloys include manganese, chromium, and ferrosilicon. Steel dominates their consumption, accounting for more than 90% of manganese and chromium demand and close to 75% for ferrosilicon. Manganese is generally used in typical carbon steels, while chromium and ferrosilicon are used more in stainless and specialty steels. Non-steel uses include non-ferrous alloys and batteries for manganese, foundries, chemicals and refractories for chromium, and iron castings and magnesium for ferrosilicon.

China’s 14th five-year plan set goals to reach peak crude steel output within the early 2020s. However, reforms are less focused on high quality and refined products, so stainless and other alloy steels will continue to see growth while Chinese carbon steel declines. As a result, global silicomanganese production will become less China-centred, while China’s share of global ferrochrome and ferrosilicon production will hold up, and even rise slightly.

Despite being a major producer of steel alloys, China accounts for only 4% of global manganese ore production and a negligible amount of chromium ore production. It is therefore becoming heavily reliant on imports of these raw materials.

In terms of the outlook for bulk alloy metals, only manganese shows any major shift in demand patterns over the long-term outlook. Several novel cathode chemistries use manganese, and this will underpin growth in demand from the batteries segment. When compared to other common cathode metals, wider geographic distribution, greater scale of production and larger reserves offer better security of supply for manganese. Moreover, production costs are an order of magnitude lower than for cobalt and nickel, which also face ESG concerns. As a result, manganese will enjoy a five-fold increase in use for batteries between now and 2040.

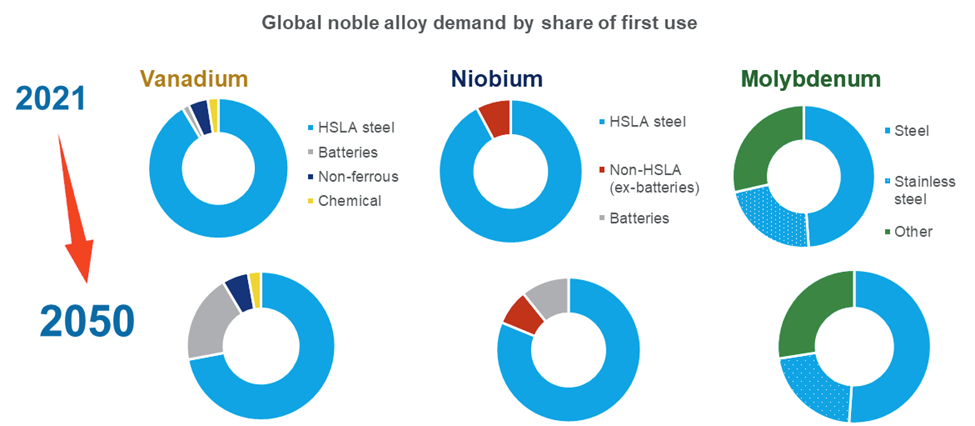

Wood Mackenzie includes vanadium, niobium and molybdenum in its noble alloys research. The use of all three is dominated by steel alloy production, which accounts for 90% of vanadium and niobium consumption, and about 70% of molybdenum demand.

Demand for noble alloys will be largely dependent on China, where crude steel output is set to decline. Despite this, demand for noble alloys will grow thanks to more stringent technical requirements for steel, especially in construction – adding very small quantities of these metals can improve properties such as strength and corrosion resistance. Meanwhile, noble alloys’ potential in lightweighting steels, energy storage and EV batteries will give them a role in the energy transition.

Most significantly, vanadium and niobium will find uses in battery applications, although the latter is still subject to technological improvements and successful commercialisation. In contrast, vanadium redox batteries (VRBs) are already being installed across the globe as part of energy storage systems (ESSs), particularly in China.

VRB uptake faces challenges relating to the cost of the electrolyte and the potential for vanadium price volatility. However, its advantages include long duration, stable chemistry and a longer lifespan than lithium-ion batteries.

Comments