How Kal Tire can solve the challenge of scrap mining tires

As Kal Tire completes commissioning a new OTR thermal conversion recycling facility in northern Chile – a first for the country – the company is excited about what this solution at the top of the recycling hierarchy will mean for mines and end-of-life tire stockpiles in Chile, and across the mining industry.

KalTireMining.com

“It’s a very important step along that road of solving the enormous challenge of scrap tires and giving mines a way to operate in a way that’s more environmentally responsible.”

Scott Farnham

Director of Recycling Services, Kal Tire’s Mining Tire Group

SOLVING THE CHALLENGE OF SCRAP MINING TIRES

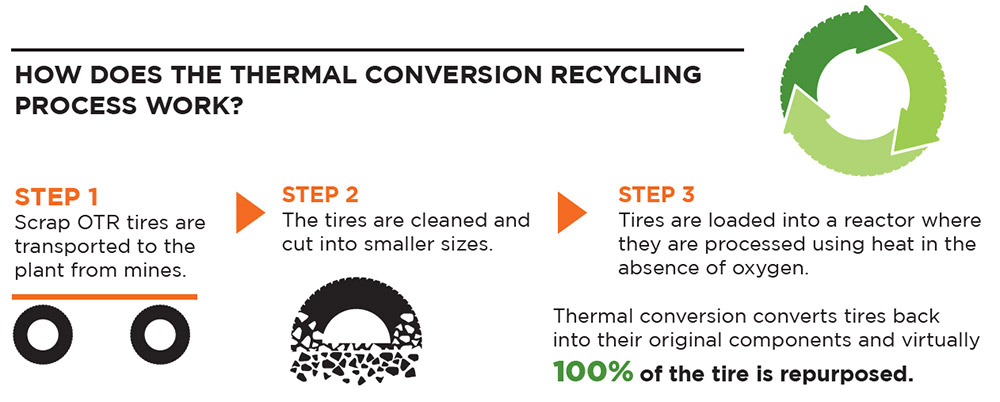

Kal Tire’s new OTR tire recycling plant in Antofagasta, Chile, employs a unique thermal conversion process that uses heat and friction to induce a reaction that converts tires into their base elements so they can be reused. At full production, the plant will recycle five 63” tires or 20,000 kilograms a day; if the plant runs a minimum of 250 days of the year, that’s 5 million kg or 1,250 earthmover tires in a year. Now, as Kal Tire begins to recycle some of the estimated 500,000 tonnes of scrap tires in Chile, the potential opportunities for reuse of the materials are growing, as is the appetite for an approach that creates this kind of circular economy. With a groundswell of interest in supporting a circular economy and ESG commitments taking greater focus in the mining industry, interest in Kal Tire’s recycling solution grows too.

Learn more about how our recycling and sustainability solutions can help your mine fulfill ESG commitments: https://www.kaltiremining.com/en/sustainable-solution/recycling/

Kal Tire’s Thermal Conversion OTR Tire Recycling Plant video

5 Comments

John Clark

Is this a tire recycle process for all tires o the planet. If “yes”, this will be a huge contribution to reducing wastes at municipal garbage dumps

Darrell Botha

Great intervention. I wouldike to run this in south Africa

Billy

It would be a good response to the current challenges posed by tire waste

samuel crisp

Fantastic. When will you adapt your process for the old horse and buggy, the automobile tires?

Wayne Johnson

What a tremendous procedure- well done hopefully we can apply this in Western Australia ?? please let me know if an opportunity exists.